Robotics in Hazardous Environments

August 14, 2017 2:44 pm

An industry insights on why use robots in hazardous environments.

Robots in hazardous environments help in preventing accidents which can cause severe threat to life of the operator, co-worker, equipment and the environment. With help of robots, some processes can be made faster, more reliable and safer. In other words, robots helps to create a safe working environment with less amount of risk and hence, helps to achieve better results. Here’s a look at what experts have to say on why use robots in hazardous conditions:

Present unique challenges

Sharing his opinion on why use robots in hazardous environments, Subrata Karmakar, Head – Robotics, ABB India Ltd says, “Hazardous applications in the manufacturing industries present unique challenges. For instance, operations such as hot billet handling for forging press, working inside a painting booth, arc and spot welding application for different automotive manufacturing industries, and handling sheet metal in a press line pose hazard to the human health. Such risky applications add challenges to the manufacturing industry’s daily operations.”

Karmakar believes however, “With the help of robotics application, we can reduce these risks and achieve better quality output. Robotics applications also improve repeatability and achieve faster production cycle with less downtime. Overall, it creates a safe working environment.”

By using robots in hazardous application, not only we try to reduce human involvement, but also improve efficiency, productivity and quality of production through Robot-based automation.

IRB 6640: Perfect robot focusing on high production capacity

ABB is one of the leading supplier of industrial robots and robot software, equipment and complete application solutions. With presence in over 53 countries, ABB has globally installed more than 300,000 robots, supported by the broadest service network and offering in the industry. Moreover, Karmakar informs, “Our wide array of robots supports different industries and applications. For instance, the IRB 6640 is the perfect robot for applications focusing on high production capacity, especially in the hazardous applications. Available in two foundry prime variants with a payload of up to 235 kg, the IRB 6640 is particularly suited for harsh washing and cleaning applications.”

Over the last few years, ABB India has installed robots in various industries and they have been effectively operating in harsh and hazardous environment. The IRB 6640 robot with 130 kg handling capacity is working in a refractory factory in the dusty and silicon particle environment, the IRB 7,600 robot handling 500 Kg load of pick and place of hot billet in the extreme temperatures of 1,100 degree, and the IRB 4,400 robot with 60 kg handling capacity for skimming application for taking the sludge out from the red hot molten aluminium in ingot manufacturing shop.”

Robotics helps to cut the accidents, injury claims.

Ajay Gurjar, Dy. COO & Head – Sales & Marketing, Yaskawa India Pvt Ltd, Robotic Division, says, “Robotics helps to cut the accidents, injury claims and health issue by removing workers from hazard and dangerous environment. Robots are generally used to perform unsafe, hazardous, highly repetitive, and unpleasant tasks. Robotics has many different functions such as material handling, assembly, arc welding, resistance welding, and machine tool load and unloads functions, painting, spraying, etc.”

Many jobs in automotive manufacturing are hazardous. Sometimes, the dangers are obvious, as when forging, welding and painting where person has to work in hot and humid atmosphere with in exposure of silica, asbestos, banzopyrene, welding fume, nitrous oxides and Isocyanates gases and impurity which create the health issue like asbestosis, COPD, lung cancer, asthma and hyper sensitivity pneumonitis. Other times, they’re more insidious, like the musculoskeletal disorders resulting from lifting, twisting and repetitive motions. Lung cancer is increased among current and former foundry workers making vehicle parts.

Gurjar informs “Historically, there has been exposure to three carcinogens in the foundry environment; asbestos, benzopyrene from the fumes of the molten metal and silica. Similar to machining, metal working fluids, called drawing compounds, are used when cold rolled steel is stamped out into metal parts (stamping) or compressive force is used on heated metal to form metal parts to conform to the shape of dies (forging). The potential for the development of asthma and hypersensitivity pneumonitis in forging and stamping would be similar to machining.”

Yaskawa’s Drip proof protection robot

“Yaskawa has Drip proof protection robot which is most successful product protection against hazards environment in term of dust, heat and water splash. Drip proof robot has one more layer of special protection coating so this Robot can perform the best in hazards environment. Yaskawa globally has proven installation of this product in foundry, forging and bricks industry which are the most hazards environment for worker,” claims Gurjar.

MA1440 and MA2010 robot model

In arc welding numerous safety risks exist for welders such as electric shock, exposure to gases and toxic fumes, and welder’s flash burns to the eyes cornea. “Robotic welders have proven themselves in reducing the number of accidents to workers in the metal fabrication industry and Yaskawa hold the no1 market share with the help of MA1440 and MA2010 robot model in India has a most preferred brand for our customer,” asserts Gurjar.

Slim, fast six-axis MA1440 and MA2010 welding robot increases productivity and achieves highest welding performance. Large 50 mm thru-hole for torch cabling, sensor wires and water cooling. Eliminates cable interference, simplifies programming and reduces cable wear.

Yaskawa Product DARWIN-Chemo Cancer-Drug Compounding Assist System (CDCAS)

The anti-cancer drugs used in chemotherapy are toxic to normal cells, so the exposure of healthcare workers to these drugs is a problem. Healthcare workers have high expectations of robots that can compound and prepare these dangerous drugs, and they believe that such robots can improve the lives of many people. However, Gurjar feels, “To achieve automation, in addition to measures against exposure, it is necessary to secure the precision and efficiency of the preparation work itself.“

Yaskawa has so far developed robots optimised for various applications such as arc welding, spot welding, painting, and clean applications. Gurjar informs, “We have continued to develop and launch new products with improved basic performance aspects such as payload, speed, environmental performance, and reliability and have also improved the ease of use. That performance has now been raised further by combining the latest Yaskawa GP/AR Series with the new model controller YRC1000, which supports the global expansion of the end users.”

In addition to new robots, Yaskawa has also developed peripheral devices such as arc welding power sources, vision systems, and force sensors and we propose these as solutions in combination with Yaskawa. This is in order to offer automation solutions for applications such as welding, painting, and handling, which is what, is ultimately demanded by the end users for hazards environment.

Helps in preventing accidents and unnecessary exposure

According to Kishan Daas GT, Business Manager-Training Academy, DiFACTO Robotics & Automation Pvt Ltd, “Robots should be used in hazardous environments to protect individuals from accidents and unnecessary exposure to noise, smoke or fumes, toxic material, bio-hazard substance, etc.” Daas feels that robots can carry out operations and process with precision and consistency, which is difficult for human operators. One such application is sampling and formulation analysis, by using industrial robots with the laboratory equipment we can get excellent throughput; using robots prevents risk of process contamination and reduced interaction with humans.

Daas adds “Robots are used in disassembly of ammunitions, like bombs and rockets. Robots can move heavy objects and parts precisely and eliminate human risk. If these tasks are not carried out precisely there is a chance of an explosion. Robots are used to handle radioactive substances in power plants, labs and in assembly of equipment’s which use such substances.”

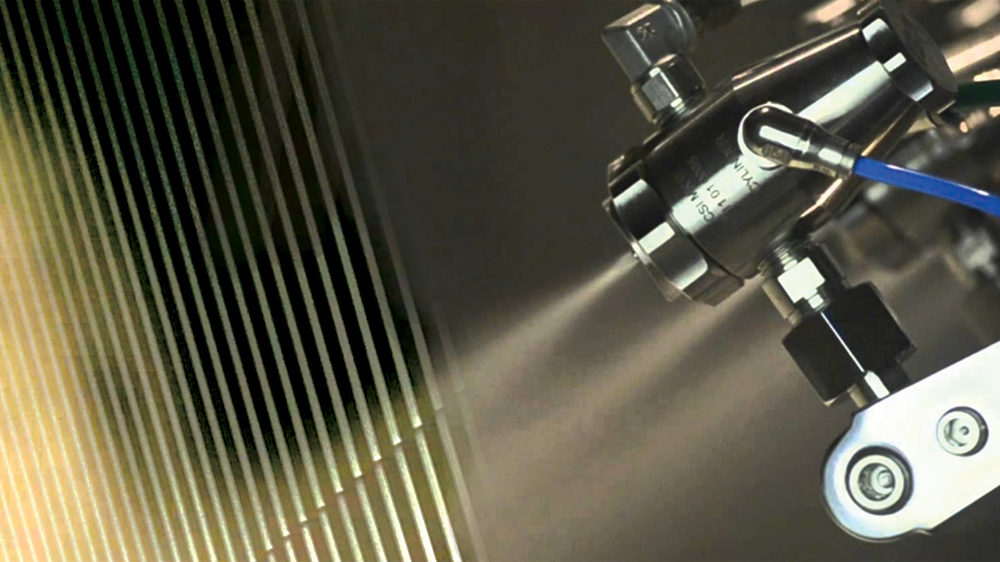

More common applications of robots in hazardous areas where high pressure fluids, like air, water, solvents, etc., are used to wash down or clean paint deposits, remove sludge, clean machined equipment, etc. Such operations pose multiple threats like they create lot of noise, the fluids can cause severe physical injury; can cause major accidents due to mishandling. Many applications in the foundry and casting plants like pouring, extraction, fettling, de-burring, handling, etc. should be automated using industrial robots and thus distancing operators from particulate matter and high temperature environments. Paint shops are explosive environment and use of robots in paint shops is highly recommended, and, apart from safety the quality of the product is enhanced by robot painting process.

“Using robots in hazardous environments helps in preventing accidents which can cause severe threat to life of the operator, co-worker, equipment and the environment,” informs Daas. “Some processes can be made faster, more reliable and safer using robots. However, robots can be integrated with additional sensors and continuous in-line monitoring and feedback mechanisms monitoring multiple parameters, which can terminate a process at the instant a threat is detected or the very moment the process parameters cross a certain value, such a capability is very limited if the case of human operator.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi