Henkel to lead today’s and build tomorrow’s adhesive markets

January 11, 2019 4:00 pm

Henkel’s LOCTITE brand is the trusted choice for engineered, high-performance adhesive, sealant and coating solutions. We combine innovation and technology to deliver product solutions that are essential to countless industrial applications. We lead today’s and build tomorrow’s markets with our technologies with strong brands in adhesives, sealants and functional coatings. Here, we present some of Henkel’s LOCTITE anti-seize compounds and the innovative Bonderite duaLCys process.

LB 8008

LOCTITE LB 8008 C5-A is an exclusive anti-seize lubricant paste in a brush top can, with copper and graphite suspended in a high quality grease. Applications include screws, nuts, pipes, exhaust bolts and brake calliper bolts. Resistant to extremely high temperatures (up to +980C) and protects from rust, corrosion, galling and seizing. It has an NLGI Grade of 0.

• Resistant to very high temperatures up to +980C

• Unique brush top

• It has an NLGI grade of 0

• Protects from rust, corrosion, galling and seizing

• Used for screws, nuts, pipes, exhaust bolts and brake calliper bolts

LOCTITE LB 8012

LOCTITE LB 8012 is a black, metal-free anti-seize lubricant with MoS2 and rust inhibitors in a brush top form. Formulated to protect assemblies during running-in periods, it resists high static loads and the MoS2 paste ensures maximum lubricity. It has an NLGI grade of one and is resistant to temperatures up to +400C.

• Metal-free

• Protects assemblies during running-in period

• Resists high static loads

• MoS2 paste insures maximum lubricity

• NLGI Grade 1

• Temperature resistant to +400C.

LOCTITE LB 8007

LOCTITE LB 8007 is an exclusive general purpose anti-seize lubricant paste with copper and graphite suspended in high quality grease. Typical applications include screws, nuts, pipes, exhaust bolts and brake calliper bolts. Resistant to extremely high temperatures up to +980°C and protects from rust, corrosion, galling and seizing. It has an NLGI Grade of 0.

• Resistant to very high temperatures up to +980C

• Unique aerosol of copper, graphite and grease

• It has an NLGI grade of 0

• Protects from rust, corrosion, galling and seizing

• Used for screws, nuts, pipes, exhaust bolts and brake calliper bolts

LOCTITE LB 8156

LOCTITE LB 8156 is a white anti-seize lubricant with mineral oil, lithium soap and ceramic designed to protect surfaces exposed to high temperatures up to +900C. It can be used on surfaces subjected to high loads/low speeds at high temperatures. It is typically used in applications with an operating range of -30 to +900C.

• Designed to protect surfaces exposed to high temperatures up to +900C

• Prevents seizing or jamming in joints exposed to high temperatures (e.g. exhausts of combustion motors and fittings or oil and gas burners).

LOCTITE LB 8023

LOCTITE LB 8023 is a black, metal-free, brush top lubricant and anti-seize made from graphite, calcium, boron nitride and rust inhibitors. ABS approved, it protects assemblies from fresh and salt water. It works especially well in high humidity conditions. It has excellent lubricity, superior water wash-out spray resistance and prevents galvanic corrosion. High temperature resistance to 1,315C.

• Metal-free

• ABS approved

• Temperature resistant to +1,315C

• Fresh & salt water/high humidity resistance

• Excellent lubricity and superior water wash-out spray resistance

• Prevents galvanic corrosion

LB 8101

LOCTITE LB 8101 is special purpose grease used for exposed mechanical systems. It is used to lubricate chains, open gears, worm screws and cables, and protects against water ingress. It also provides excellent resistance against wear and withstands high pressure. The product is also designed to resist centrifugal forces on high speed mechanisms. It is typically used in applications with an operating temperature range of -30C to +170C.

• Chain lubricant

• Special purpose grease for exposed mechanical systems

• Protects against water ingress

• Excellent wear and high pressure resistance

• Lubricates chains, open gears and worm screws

• Operating temperature range of -30C to +170C

LOCTITE LB 8103

LOCTITE LB 8103 is a black, mineral oil and MoS2-based grease, which is suitable for heavy loads, withstands vibration and can be used on moving parts at all speeds. This is also suitable for higher-stressed joints, plain- and roller-bearings, socket joints and slideways. It has an NLGI Class 2 rating and can withstand temperatures to +250C.

• Suitable for heavy loads and withstands vibration

• For moving parts at all speeds

• For higher-stressed joints, plain- and roller bearings, socket joints and slideways

• NLGI Class 2

LOCTITE LB 8104

LOCTITE LB 8104 is a colorless grease based on silicone and thickened with silica gel. It has a wide temperature range (up to +200C), lubricating most plastics and elastomeric components. It has an H1 NSF Reg No of 122981 and is graded NLGI Class 2/3.

• Silicone grease

• Valve and packing grease

• Wide temperature ranges up to +200C

• Lubricates most plastic and elastomeric components

• H1 NSF Reg No.: 122981

• NLGI Class 2/3

LOCTITE LB 8035

LOCTITE LB 8035 is a brownish, water miscible cutting fluid, primarily for general automated machining of all steel and cast materials. It is also suitable for aluminium and non-ferrous metals. Although this emulsion is bactericide-free it is highly resistant to micro-organisms, bacteria and fungi. This clean running fluid provides excellent cooling and lubrication and is also low foaming.

• Universal application

• Bactericide-free

• Highly resistant to micro-organisms, bacteria and fungi

• Excellent cooling and lubrication performance

• Low foaming

LOCTITE LB 8711

LOCTITE LB 8711 (known as LOCTITE PENETRATING ) is a brown, thin, solvent-based, liquid aerosol lubricant, standard ‘tool’ for disassembly and assembly of machinery, piping, valves and other metal fitted parts. As a lubricant it deposits a thin, oily coating that displaces water and moisture under the most severe conditions. It also prevents rust and allows for smooth movement of metal parts.

• Aerosol

• Standard ‘tool’ for disassembly and assembly of machinery, piping, valves and other metal fitted parts

• Prevents rust and allows for smooth movement of metal parts

LOCTITE LB 8040

LOCTITE LB 8040 is a special mineral oil designed to free rusted, corroded and seized parts. The shock-freezing effect will cool parts instantly down to -43C and cause microscopic cracks in the layer of rust. This allows the lubricating ingredients to wick directly into the rust by capillary action. The product leaves a thin film on the released parts that lubricates and prevents rust. It is used for emergency repair, as it releases rusted, corroded and seized components.

• Universal application

• Bactericide-free

• Highly resistant to micro-organisms, bacteria and fungi

• Excellent cooling and lubrication performance

• Low foaming

LOCTITE TG 100

LOCTITE TG 100 is recommended for high-temperature heat transfer in normal applications. It is used between heat generating devices and the surfaces to which they are mounted or other heat dissipating surfaces. This product delivers excellent thermal resistance, offers high thermal conductivity and virtually no evaporation over a wide operating temperature range. It is nonflammable, oxidation resistant and does not promote rust or corrosion.

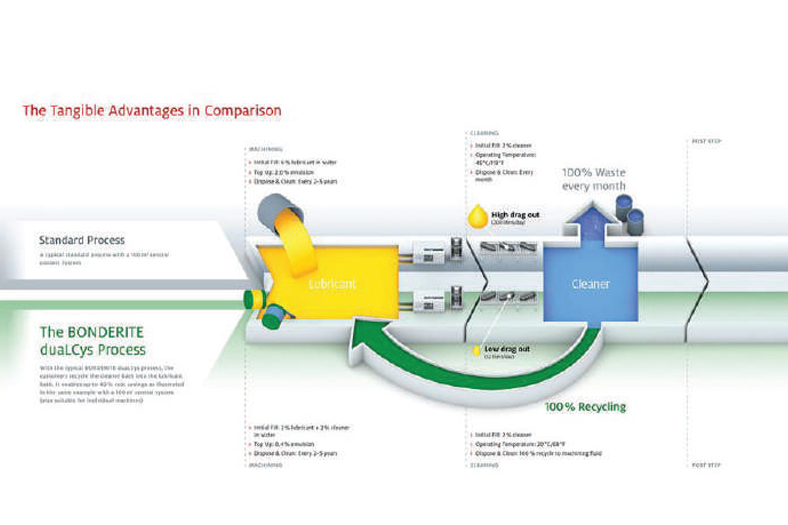

Henkel’s Bonderite Dualcys Process is fast establishing itself as a game changer for greater efficiency and safety in machining and cleaning. Two years after it was first introduced to the metalworking market, Henkel’s innovative Bonderite duaLCys process has proven its superior cost-efficiency and sustainability over conventional cooling lubrication and cleaning processes. Most recently, the process demonstrated these advantages in a demanding precision tool machining project at German customer Mapal.

Bonderite duaLCys is part of Henkel’s comprehensive portfolio of process solutions for the metalworking industry that can be tailored to the precise needs of customers across their entire value chain from casting and machining to assembly. The innovative duaLCys technology offers significant improvements in all competitive criteria, including time, fluid and energy consumption as well as product quality and process safety. Essentially, it leverages the synergies between the process fluids by recycling the cleaner into the lubricant bath rather than discarding it as waste.

Inspired by the bactericide-free duaLCys technology, Henkel has developed an entire range of standard and specialised, one-component products:

• Bonderite L-MR 20717 is the all-rounder, suitable for nearly every machining operation, to include a wide variety of operations and materials.

• Bonderite L-MR 21164 is designed for the machining of various specialised materials such as brass, copper, zinc-coated, aluminium alloys, and pure magnesium. It also provides stability in very hard water conditions.

All the products are free of both boron and formaldehyde, and offer excellent bio -stability, corrosion protection, high lubricity and good cleaning ability. Featuring very fine dispersion, they also function well in a wide range of water hardness and applications, and deliver improved sustainability as well as significant cost savings.

Over all systems and customer installations in the past 18 months, Bonderite duaLCys has reduced the cooling lubricant consumption by 60 percent. The process has been widely adopted for almost all metal substrates throughout the automotive industry and is fast entering other market segments.

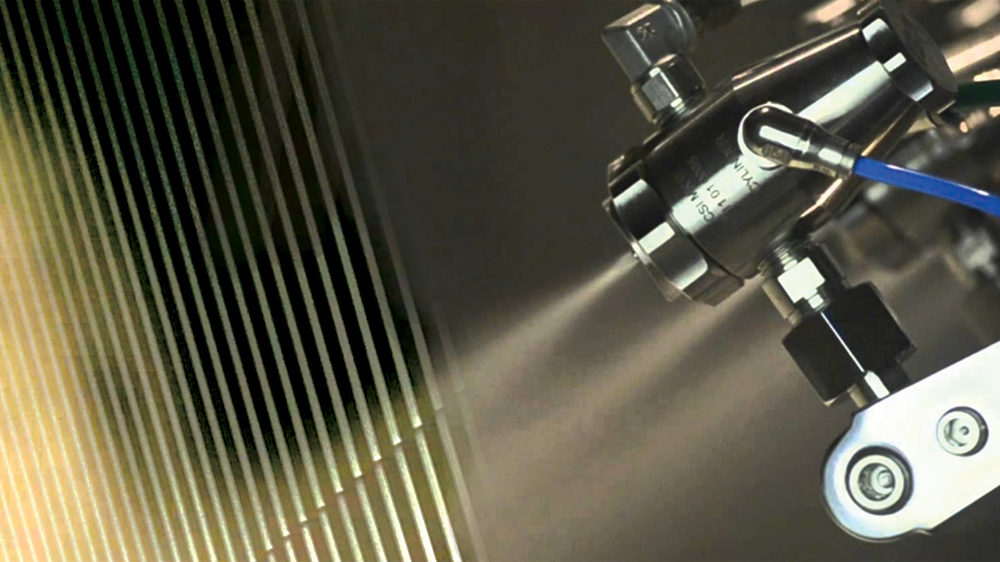

Henkel’s duaLCys process utilises the synergy between a lubricant and a cleaner: Bonderite C-NE 10466 high-performance, water-based neutral cleaner, and Bonderite L-MR 21466 cutting fluid. The cleaner produces no foaming in most common water hardness, provides excellent corrosion protection and can be used at room temperature. The machining fluid is a finely dispersed lubricant. Both are free of boron and bactericides and have very strong bio stability. The system is suitable for most metal substrates, including steel, stainless steel, cast iron and aluminium alloys.

The Bonderite duaLCys process requires less water and saves energy by allowing the cleaner bath to operate at a reduced temperature.

In addition to minimising waste while delivering low reject rates and high surface quality, Bonderite duaLCys also offers improved working conditions resulting from the use of safer, more predictable solutions. In the automotive industry, the process can provide a competitive edge to OEMs, Tier 1 suppliers and machining companies alike by enabling a more cost-effective, sustainable way of manufacturing metal parts such as powertrain components, wheels, HVAC compressors and other machined parts.

“The Bonderite duaLCys process is a unique concept in the area of machining and in-process cleaning for the metalworking market,” adds Desinger. “Recycling the cleaning fluid instead of throwing it away, and making use of its synergies with the water-soluble cutting fluid, results in an excellent combination of high lubricity, superior part cleanliness and excellent corrosion protection.”

Enhanced lubrication for longer tool life

Machining tools last much longer in operations using Bonderite duaLCys, thanks to its much higher lubricity as well as its superior cleaning capability, compared to conventional products. The lubricant also features pre-cleaning properties due to its combined formulation. Operations can save up to 40 per cent in process costs and reduce lubricant drag-out by as much as 70 per cent.

For more details, contact:

Henkel Adhesive Technologies India Private Limited

www.henkel.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi