E-Mobility and Die & Mould

October 1, 2020 9:53 pm

How e-mobility will drive the demand for die & mould in India?

Electric Vehicles (EVs) provide great potential to drastically reduce local air pollution, greenhouse gas emissions, resulting climate change impacts, and oil use from the transport sector. Governments across the world are extending their supports for introduction of EVs. The Indian government had also launched the FAME scheme (Faster Adoption and Manufacturing of Hybrid & Electric Vehicles in India) in 2015 under the National Electric Mobility Mission Plan (NEMMP), to promote faster transformation from Internal Combustion Engines (ICE) to EVs. According to Society of Manufacturers of Electric Vehicles (SMEV), in India, EV sales, excluding e-rickshaws, grew by 20 per cent at 1.56 lakh units in 2019-20 driven by two-wheelers.

As per a new study by Castrol, most consumers in India would consider buying an EV by 2022, but most also believe that it won’t be until 2025 that the majority of new cars purchased are electric.

Generally, thousands of stamping dies sets are used for a car, which accounts for about 40 percent of total output value of the car. Also, a huge volume of plastic mould, sheet metal mould and die-casting mould are used. Further, a majority of parts in automotive production rely on mould forming. Thus, die and moulds are critical components of automotive industry.

With increased emphasis on green mobility, a major shift in automotive manufacturing is being witnessed on the road from ICE to EVs. This move is transforming the die and mould industry as well.

So, let us understand the EV industry from die and mould industry’s point of view. According to Vivek Nanivadekar, Executive Director, FIBRO India Precision Products Pvt. Ltd., “The ICE and its power transmission and related components will be replaced by batteries. As such dies and moulds required in ICE technology will be replaced by dies and moulds required in batteries and it`s power transmission. Everything such as bonnet, boot, doors etc. in vehicle will remain the same. In fact due to miniaturisation of batteries and power transmission components, control panels and overall use of improved smart technology in the vehicle, the requirements of high precision dies and moulds will become more critical.”

In addition, the faster obsolescence of technology will demand high precision dies and moulds at the shortest lead time. In Nanivadekar’s opinion, this will also call for change in designing and manufacturing technology of dies and moulds. The basic metal of dies and moulds could be replaced light weight non-metallic material and subtractive manufacturing could be replaced by additive manufacturing. The possibilities are limitless but the principally the dies and moulds would remain as important catalyst in EV, he observed.

Vishal Bagthadia, Sr. Application Engineer, DesignTech Systems explains, “If we compare a traditional vehicle with an EV, the major difference is that the ICE and exhaust system are replaced with the battery pack, motors, power electronics and electric-driven powertrain. However, vehicle systems like e-braking, suspension, steering, interior, frame and body parts will still be part of an EV.”

The design and manufacturing of dies and moulds represent a significant link in the entire production chain because nearly all mass produced discrete parts of EV which are mentioned above are formed using production processes that employ dies and moulds. Therefore, the die and mould industry will still play a vital role in manufacturing of these components, said Bagthadia.

How e-mobility will drive the demand for die and mould in India

The weight of an EV is significantly higher than of an ICE vehicle. Thus one of the trends in the EV industry emphasises on light-weighting which often leads to complex designs for manufacturing. During the process of developing light weight designs, the companies need to consider vehicle safety norms, performance criteria as well as manufacturability. This can be achieved with structural optimisation techniques used during virtual simulations with due considerations of manufacturing processes like casting, forming, injection moulding, etc.

Commenting on how e-mobility will drive the demand for die and mould in India, Nanivadekar said, “There will be demand for higher precision in die and mould. Indian tool rooms (should) start preparing themselves in terms of knowledge, machining techniques etc. to meet the challenges. There is a need to upgrade the training centers to produce the tomorrow`s die makers. I am afraid otherwise India will be only CKD (completely knocked down) assembly center.”

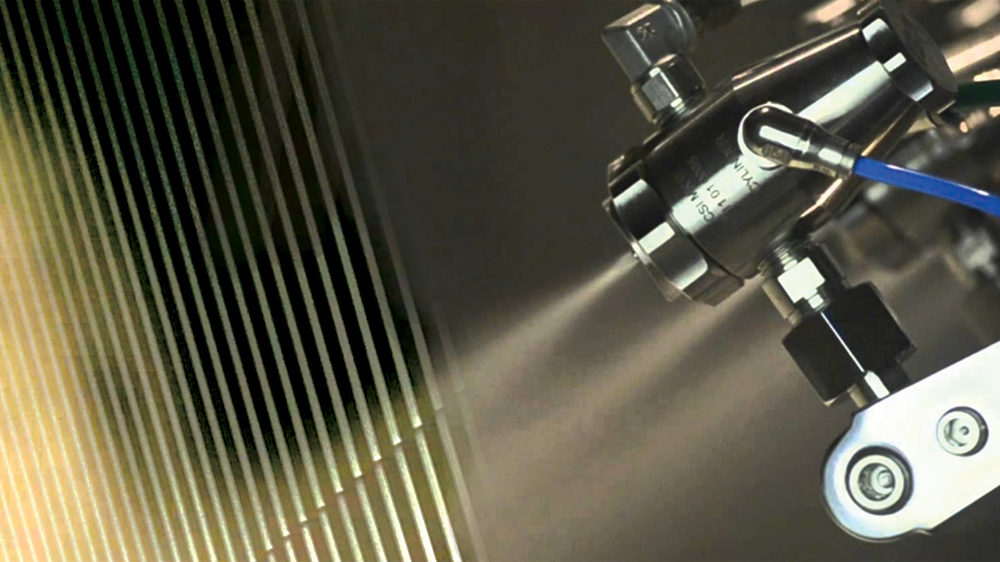

Bagthadia said, “With increase in demand for high precision and complex designs for manufacturing, die and mould makers in India will be compelled to develop and implement the latest technology in part and process design including process modelling, rapid prototyping, rapid tooling, optimized tool path generation for high speed cutting and hard machining, machinery and cutting tools, surface coating and repair.”

Nanivadekar recommends, “Upskilling is the mantra to meet the ever changing requirement of die and mould. Die and mould is the fundamental need of engineering industry and it will remain forever in one form or other.”

Expertise of FIBRO India in EV

FIBRO has two verticals – Rotary Tables and Standard Parts for die and mould. “Our Rotary Tables for automation will not have any adverse impact by e-mobility, rather the demand would increase. We are ready to meet the demand of tomorrow`s automation,” Nanivadekar states.

For example, FIBRO has Direct Drive rotary table with stepless RPM monitoring. In the field of Standard parts, the company is closely working with auto OEMs and manufacturing or developing the standard parts accordingly, informs Nanivadekar. He adds, “We have remote sensing of pressure of the nitrogen gas springs in operation used in dies. Similarly, we have electronic tapping unit used in the press tool. We also have range of sensors to qualify the equipment for Industry 4.0.”

Expertise of DesignTech Systems in EV

DesignTech Systems is a CAD/CAM/CAE, PLM solutions and additive manufacturing technologies provider in India. According to Bagthadia, currently simulation is playing an important role in the ongoing improvement of EV technology in discovering new ways to augment innovation, boost efficiency, and performance, while reducing costs and time of development. It can also provide accurate results to measure performance at the earliest possible design stage.

DesignTech Systems provides a range of solutions covering various technology disciplines of an EV such as motor design, battery pack design and validation, battery thermal management, external aerodynamics, structural design & analysis, crashworthiness, manufacturing simulations, EMI/EMC, antenna design & IoT, vehicle dynamics, math & system modelling and many more.

Quotes

Upskilling is the mantra to meet the ever changing requirement of die and mould. Die and mould is the fundamental need of engineering industry and it will remain forever in one form or other.

Vivek Nanivadekar, Executive Director, FIBRO India Precision Products Pvt. Ltd.

With increase in demand for high precision and complex designs for manufacturing, die and mould makers in India will be compelled to develop and implement the latest technology in part and process design…

Vishal Bagthadia, Sr. Application Engineer, DesignTech Systems

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi