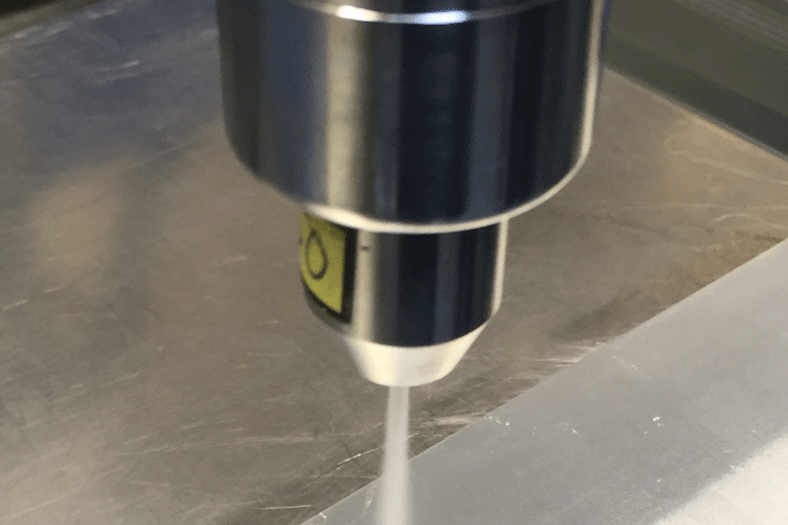

Optimum preparation of bonding sites with CO2 snow

July 9, 2020 12:00 pm

Cleaning structural joining surfaces effectively and efficiently

In order to save weight, an increasing number of assemblies used in the automotive industry today are made of plastic or lightweight metal which need to be glued together. The reliable pretreatment of the joining surfaces is a must, especially where structural components are concerned. This is where quattroClean comes into play. The climate-neutral technology has a number of advantages over other dry cleaning processes.

Lightweight construction is not new to the automotive industry. However, as electromobility is becoming more popular and CO2 emissions continue to be reduced, this topic is becoming increasingly relevant. OEMs and suppliers are therefore turning to lighter materials such as aluminum and plastics for body parts, e.g. doors, vehicle roofs, trunk lids, tailgates and engine hoods. Changes in manufacturing and joining methods such as bonding instead of welding, riveting or screwing, enable further weight savings. To guarantee the necessary adhesive strength when bonding structural body parts or battery housings, for example, the joining surfaces must meet high cleanliness and wettability requirements.

Efficient partial dry cleaning instead of full-surface wet cleaning

For various reasons, conventional wet-chemical cleaning processes with water-based media or solvents are not suitable for this. Among others, the areas to be joined invariably have to be much cleaner than the rest of the component. Such cleaning processes cannot be integrated into a production or assembly line – or can only be integrated with extreme effort. Consequently, dry processes are preferable, for example the environmentally-friendly quattroClean snow jet cleaning technology from acp systems AG. It is implemented in a wide range of industries for the selective or full-surface cleaning of components made from practically all types of material. The cleaning process is so gentle on materials that even delicate substrates can be treated.

The cleaning medium used by the technology is liquid carbon dioxide, which is generated as a by-product from chemical processes and energy generation from biogas and therefore environmentally neutral. It is guided through a wear-free two-component ring nozzle and expands on exiting to form fine CO2 snow. This core jet is then bundled by a separate jacketed jet of compressed air and accelerated to supersonic speed. When the easily-focused jet of snow and compressed air impacts on the surface to be cleaned, a combination of thermal, mechanical, sublimation and solvent effects occur. The interaction of these four mechanisms of action detaches particulate (e.g. dust, chips, abrasion, micro burrs) and filmic contamination (e.g. separating agents, drawing oils, emulsions, silicones, traces of powder) in a reproducible manner. The aerodynamic force of the compressed air carries away the detached contamination, which is then removed by an integrated extraction system.

Cold, easily-automated cleaning process with wide operating window

Developed more than 20 years ago, the quattroClean technology is one of the most efficient, effective and versatile dry processes on the market. Various process-related properties enable the technology to achieve better and more reliable results in series production than other dry cleaning methods such as atmospheric pressure plasma or laser cleaning. It is also more robust and has a wide operating window. A further advantage is that the component areas to be treated do not become hot when they are cleaned.

Thanks to the scalability of the industry 4.0-compatible quattroClean system, it can be easily adapted to different applications and component geometries in a space-saving way. All process parameters, such as the volume flows for compressed air and carbon dioxide, the number of jets and length of time and area the jet is applied to, are precisely tailored to the respective component as the result of pilot tests performed in the acp technical center. The parameters also take material properties and the type of contamination requiring removal into account and can be filed as part-specific cleaning programs in the system controls. Tailored system concepts are developed by acp on the basis of standard modules. These take the form of stand-alone solutions and as well as systems for integration into production lines and networked manufacturing environments.

Adhesive pretreatment of structural components made of plastic and metal

The quattroClean process established itself over atmospheric pressure-plasma cleaning as a pretreatment (removal of separating agent residues and surface activation) for two parts to be joined that are made of fiber-reinforced polyamide (PA) and non-reinforced PA. Components cleaned by plasma were unable to meet the requirements of the destructive adhesion test carried out after bonding. Furthermore, the narrow window of the plasma cleaning process meant that parameters such as exposure time, distance and angle of incidence of the plasma had to be strictly observed in order to clean the surface effectively and not overactivate the plastic. For this application, acp worked together with the company to develop a multi-stage process in which the components are not only cleaned automatically but also activated and bonded.

An Asian OEM was looking for a process to remove minimal amounts of residues of drawing oil from formed aluminum body parts before bonding. The company carried out comparative tests with plasma, laser and quattroClean cleaning technologies. While the plasma process proved to be unsuccessful, laser cleaning was able to remove the drawing oil. However, the component became hot during cleaning, which resulted in undesirable side effects. This was an exclusion criteria, as was also the relatively low speed of the process. In addition to achieving the target cleanliness values and demonstrating high process speeds and reliability, the quattroClean process also impressed with its robustness and cost-effectiveness. According to the OEM’s calculations, investment costs are only a quarter of those for a wet-chemical process, and operating costs are less than half.

For more details, visit: www.acp-systems.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi