Connecting the physical and virtual worlds

June 11, 2018 5:58 pm

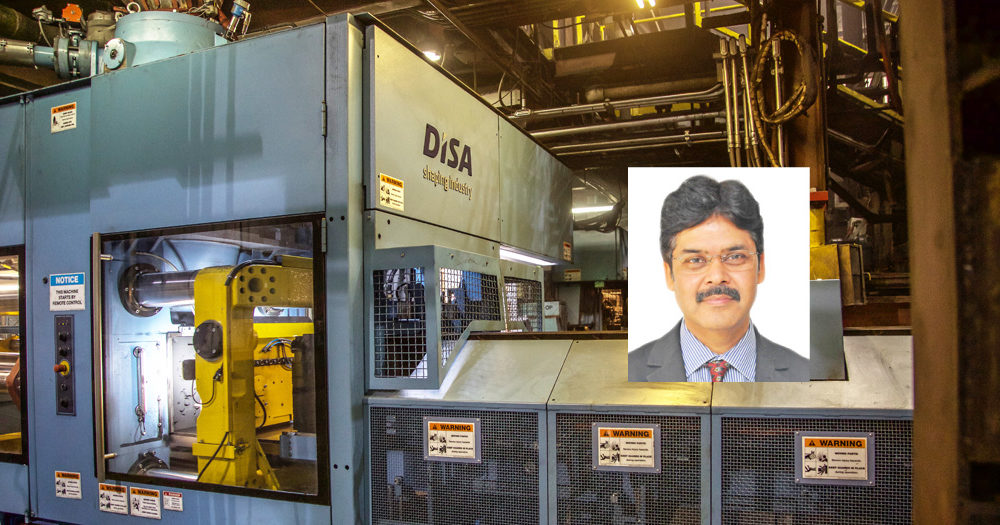

Lokesh Saxena,

Managing Director, DISA India Ltd

Tomorrow’s interconnected factories will offer completely new opportunities for optimisation, as well as reducing energy consumption and waste at all stages of production.

IIoT and the future of manufacturing

The Industrial Internet of Things (IIoT), is part of what has been hailed as the fourth industrial revolution (Industry 4.0), in the course of which physical and virtual worlds connect. The word ‘revolution’ gives a clue to the type of change one can expect to see. Lokesh Saxena, Managing Director, DISA India Ltd, says, “Tomorrow’s interconnected factories will offer completely new opportunities for optimisation, as well as reducing energy consumption and waste at all stages of production. The change will be profound, but not unfamiliar.”

He adds, “Digital transformation is a phenomenon we have been encountering throughout society. It’s changed how we use taxis, how we buy things and how we communicate. It includes things like smart homes, smart cities, and smart factories. Industry 4.0 could also be described as “smart industry” – it’s the industrial version of digital transformation.”

Industry 4.0 has started to arrive in the industry, foundry industry as well. Basic technologies like machine-to-machine (M2M) communication or remote monitoring services (RMS) have been in use for a while, sowing the seeds of digital transformation.

Customers here at DISA, are seeking foundry solutions from global organisations to help them unlock the full potential of Industry 4.0. Much more is still to be done to fully achieve this, both on the side of equipment manufacturers and its foundry customers.

In future, equipment data from foundries will be integrated to make key information and insight available to plant directors instantly, enabling them to take suitable proactive, predictive and corrective actions to maximise Overall Equipment Efficiency (OEE) as well as efficiency, output quality and productivity of the foundry as a whole.

This may start by working towards more localised solutions in an initial phase, and then builds on those localised solutions to expand them into cloud applications. Eventually, this will create a powerfull web of actionable information exchanged and shared between foundries, customers and suppliers.

IoT and data technologies are easier to adopt

Saxena believes no industry will remain untouched by IIoT. However, many IIoT and data technologies are easier to adopt in very controlled processes and environments – automotive assembly lines, for example. Processes like metal casting are highly technical, but also slightly less easily controllable – due to the myriad of external factors impacting on them.

An assembly line, on the other hand, is about logistics and orchestration, something that is much easier to capture with IIoT technology and for which solutions can be easily transferred between industries. The foundry industry will be applying IIoT and other digital technologies to its unique technical processes, so it won’t be able to borrow as much from other industries and it might therefore take it a bit longer than others to implement Industry 4.0 deeply and on a large scale. Saxena adds, “It’s certainly a much trickier challenge and feels that it as our role at DISA to help foundries accelerate their IIoT adoption and develop the best solutions faster.”

The other dimension to look at in terms of ease of adoption is scale. Mass production industries will see higher and faster levels of IIoT adoption – sectors like automotive manufacturing or precision components, and process industries like oil and gas, pharma and power – because they will see big returns more quickly.

Security vulnerability will drive a careful evaluation of the implementation of IIoT, in addition to a sound business case and a good ROI over time.

DISA’s preparedness in the area of IIoT

Saxena informs, “For us here at DISA, and indeed across the wider Norican Group, the focus is less on ourselves and more on our customers’ readiness for IIoT. Within DISA, we have been working on solutions that create the foundations for IIoT in foundries, developing data platforms and solutions that work in foundry contexts and with the very specific technical processes of that industry in mind.”

Saxena further added, “We tackle this for our customers from two ends: firstly, we’re developing standalone innovations that use data and connectivity to deliver a specific benefit or payback; secondly, and in parallel, we are creating overarching data foundations that will eventually connect the whole foundry.”

Taking both of these approaches at the same time means that the customers can benefit from data, analytics and IIoT now, justifying the investment with a clearly defined payback, while they can rest assured that all these seemingly isolated solutions will be able to connect as a whole in future.

Examples for these two approaches are company’s recently launched DISA MAC and DISA Foundry Cockpit. The former is a device that collects and analyses dimensional data of moulds in real time and, using clever software, prevents less-than-perfect moulds from being poured, saving foundries a lot of money on avoidable scrap and rework. The DISA Foundry Cockpit is a data platform for foundries that could, ultimately, run on any piece of foundry equipment, enabling analysis of data across foundry processes to continuously optimise production. It also lays the foundation for advanced use of data for machine learning and AI. The important detail here is that the DISA MAC already works using the DISA Foundry Cockpit, but one doesn’t have to buy into a huge foundry-wide data system.

He adds, “These two solutions were developed in-house at DISA, but within the Norican Group we and our customers now also have the services of Norican Digital at our disposal. Norican Digital brings together the combined experience of the Norican Group, knowledge of the industries we serve and the emerging digital technologies that can help our customers thrive. This centralised resource allows us to accelerate the development and adoption of technology in a way that is robust, proven and makes sense for our customers. Norican Digital will give our IIoT efforts a huge additional boost – something our customers will notice very quickly.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.