The fabrication industry is benefiting from computer-aided manufacturing

February 13, 2023 1:53 pm

The market’s growth is expected to be aided by rising demand for machining and efficient fabrication techniques.

Several factors like new infra projects initiated by the government, modernisation of Railway infrastructure and manufacturing facilities, development of Metro networks in all majors cities of India, privatisation and modernisation of defence projects under the “Make in India” and “Atmanirbhar Bharat” initiative from government driving the metal fabrication industries in India.

Metal fabrication industry in India

The big cluster of MSMEs present in India is actively supported by the government and acts as a driving force to boost the metal fabrication industry. As demand grows, the skilled workforce and automation requirements are also increasing. Optimisation of the fabrication process is essential to match the global standard in terms of quality and also to become price competitive on the world stage.

Rising demand for metal processing and machining

The increasing demand and supply for metal fabrication across numerous industries, such as automotive, aerospace, military, and manufacturing, are expected to boost market growth. The market’s growth is expected to be aided by rising demand for machining and efficient fabrication techniques. The growing demand is fueled by programmed production techniques in the element fabrication sector, which aids in the creation of trustworthy fabrication amenities. Increased advancements in sectors like computerisation and robotics are paving the way for new technologies and solutions to be implemented in the metal fabrication market. It is expected to rise in the next year due to increased demand for metal processing and machining in various growing economies worldwide.

The Indian Metal Fabrication Market is anticipated to register a CAGR of greater than 5 percent during the period 2022 – 2027. It is considered one of the fastest-growing markets in the global metal processing industry. The main advantage of the metal fabrication industry of India is the availability of a workforce at a competitive cost.

The Indian metal fabrication market is fragmented, with many small- and medium-sized companies and EPC companies. The rising demand for goods and services across various sectors in India, combined with the fact that global manufacturing companies focus on diversifying their production by setting-up low-cost plants in countries like China and India, is expected to drive the Indian manufacturing sector.

Thermal cutting processes in metal fabrication operations

Metal fabrication is one of the integral parts of industrial operations. It involves several processes that are used to cut, shape, or mould metal structures into the final product. Any fabrication operation starts mainly with the cutting process.

Let’s talk about the steel industry and three primary metals, i.e., Carbon Steel, Stainless Steel and Aluminium. The cutting process will be carried out mainly by plasma, oxyfuel, laser, and waterjet processes. In India, the plasma, oxyfuel and laser cutting processes drive the fabrication industries on huge scales.

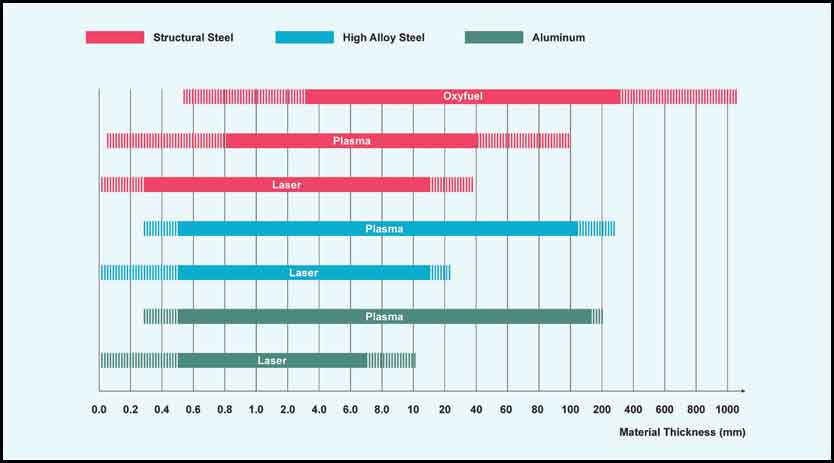

Selecting the proper process for the appropriate application is critical and will give a competitive advantage in industries. In the battle to reduce costs, engineering and manufacturing departments constantly look for an edge. The graph below will provide clear ideas for selecting the cutting process if we discuss the application area for the thermal cutting process.

Oxyfuel process

In certain applications, even though this process has certain limitations, you cannot have an alternative for this process. To optimise this process and reduce the cost of operation, We Messer has introduced a unique torch, “ALFA “, to carry out this process in the most optimum way to reduce the cost and improve the cut quality. Additionally, this torch will reduce operator skill requirements to carry out the Oxyfuel process. Furthermore, an automatic inbuilt ignition inbuilt height control system will also reduce gas consumption during operation and optimise the uses of plates.

The second critical process is the plasma process. This process has also involved improving its footprint in fabrication industries over decades. This process started with Air plasma and oxygen plasma and is now upgraded to high-definition plasma resulting in improved consumables life, cutting quality and productivity.

Most fabrication industries are also engaged in edge preparation of the plate for welding surfaces. In this scenario, plasma cutting with a bevel will play an important role in providing the optimum solution. We Messer, are pioneers in providing solutions for edge preparation in fabrication industries. Our newly introduced, high-speed ELEMENT machine with a bevel tool is the perfect solution for this requirement. Our bevel machines are successfully working in good yellow Industries, shipbuilding, windmill and railway industries worldwide.

Laser cutting, particularly fiber laser, is the latest trend in sheet metal industries. Every fabrication industry, particularly thin sheet industries, wants this process due to cost-effectiveness, cutting quality and high productivity. Fabricators need to choose the right products for their application.

Messer India offers a very reliable and unique solution in this process. Our Flagship products, like FiberLight and FiberBlade machines, are catering these industries.

Advancements in technological tools for metal fabrications

The metal working market uses a variety of ERP technologies and software. This facilitates data access and speeds up the decision-making process. Companies in the metal fabrication industries are benefiting from an increase in the use of computer-aided manufacturing technologies, which is helping them improve operational efficiency and production.

Material handling process for thermal cutting machine duty efficiency

Plate/ Material handling also plays a vital role in the productivity of any fabrication unit. Processes like laser and plasma need huge material handling requirements to feed the machines and remove the cut parts. We are witnessing a major bottleneck in today’s fabrication industries due to poor infrastructure for Material handling in fabrication units. Even though cutting equipment is very reliable, has high speed and capability to run 24X7, utilisation of this equipment is not increasing more than 60 percent to 70 percent most of the time, mainly due to infeed and outfeed or availability of proper material Handling in units. Material handling is key for any fabrication unit to optimise world class equipment. And as always, Messer India is always a pioneer in visualising fabrication industries’ requirements and coming out with solutions for Material handling. We have recently launched a cost-effective material handling solution for fabrication industries, particularly for Plasma and Laser cutting processes.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.