The journey towards a Connected Enterprise

December 11, 2017 12:27 pm

“While the industry sets a digital, connected enterprise as a norm across businesses, another factor that would propel the transformation faster is regulatory intervention which sets the setting for the industry-wide revamp.”

The term Industry 4.0 is fast becoming a cliché in the business world. Along with it comes a plethora of subjects, ranging from digital disruption, data, analytics to connected devices – all of which are now becoming necessary concepts to be imbibed in the core goals of a company. Connectivity is ramping up each day and devices are no longer standalone devices today.

If estimates from a Gartner report from February are to be believed, the world will witness 8.4 connected devices that fall in sync with the Internet of Things (IOT) this year, and by 2020, the number will rise to 20.4 billion. For companies, this means terabytes of data flowing in and an increased spending on endpoints. The Gartner report estimates that figure at $2 trillion for this year. As jarring as these figures may seem, there is an inherent reason why companies have big plans for Industry 4.0 and the answer lies in the abundant opportunities that arrive with it. While companies get on the bandwagon of becoming more agile by using smart devices, the most promising aspect of imbibing new-age technologies lies in minimising surprises or shocks with constant monitoring. The technologies have further paved the way to significantly boost efficiency and performance rates while keeping processes and operations flexible by revamping every functionality in an organisation.

Digital processes are now being innovated upon and companies are increasingly forming ways to connect shop floor and top floor seamlessly. The idea being that it saves time to boost productivity in a company – a core goal for companies that have remained unchanged over the years. This one aspect has stayed along the era of assembly line to now where the demand is tilted towards creating tailor-made products, considering customers’ insights and needs. Industry 4.0 promises an uninterrupted production cycle with minimal downtimes, while adding a cherry on top in terms of flexibility and efficiency. The market today strives for connected enterprises that simplify the core goals and break barriers with integrated controls and information. Taking an enterprise with old and archaic systems on this journey, however, remains the biggest challenge. The ideal roadmap for this would be a combination of greenfield pilots and brownfield step by step transition. After all, we cannot boil the ocean, given the limited budgets and the bandwidth to execute large transitions without affecting business as usual.

Revamping processes

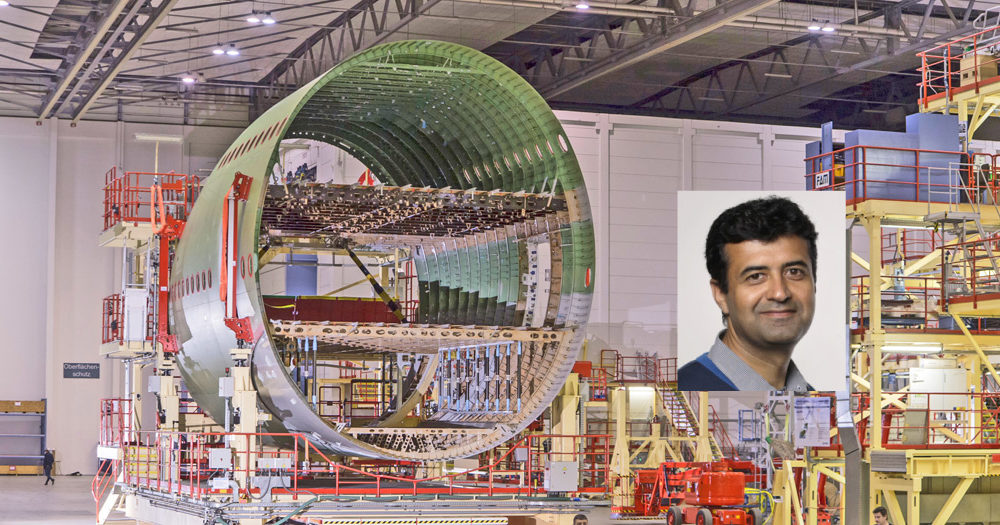

One of the biggest changes that an organisation vying to become a connected enterprise will have to shoulder is refurbishing its processes. A connected enterprise warrants staying connected with the end user on each stage of creating a product – from design to the market. For establishing a truly connected enterprise, there is a need to automate processes to minimise human interference, which thereby allows uninterrupted work.

This approach requires installing remote monitoring devices like sensors and analytics that keep an eye out for anything out of the ordinary, along with a central backend system that keep processing data to filter out relevant details. For a company like Tata Technologies which has joined the bandwagon helping organisations to become a connected enterprise, the work towards creating central systems has been an ongoing effort. For one automotive company, we created a central system that could connect over 1,000 dealers to a factory network, which helped deliver automation, data authenticity, and attain real-time market information. In another instance, we used advanced analytics to help another automotive manufacturer to increase their sales by using advanced analytics that could decode the purchasing pattern of the customers.

Such advancements and central systems form the base of a connected enterprise that can cut human interference and boost efficiency – the core pillar on which a connected enterprise stands on. They set the base for processes to become continuous while existing systems are upgraded for an enterprise to become truly connected. Technologies like constant monitoring, data analysis and predictive analysis, Manufacturing Execution System (MES), top floor to shop floor connectivity, digital designs – all contribute to create a holistic organisation that thrives in connectivity.

At par with technology

The idea of rehashing these technologies is incomplete without access to and leverage of high-end technologies that are now becoming a norm of life. The time is now ripe for industries to redefine traditional machinery design approaches to imbibe new ways of manufacturing that hold the promise of high productivity and efficiency. The steps towards imbibing connected enterprise by way of technology is based on five key elements and one paramount aspect to this is putting in place an integrated safety process.

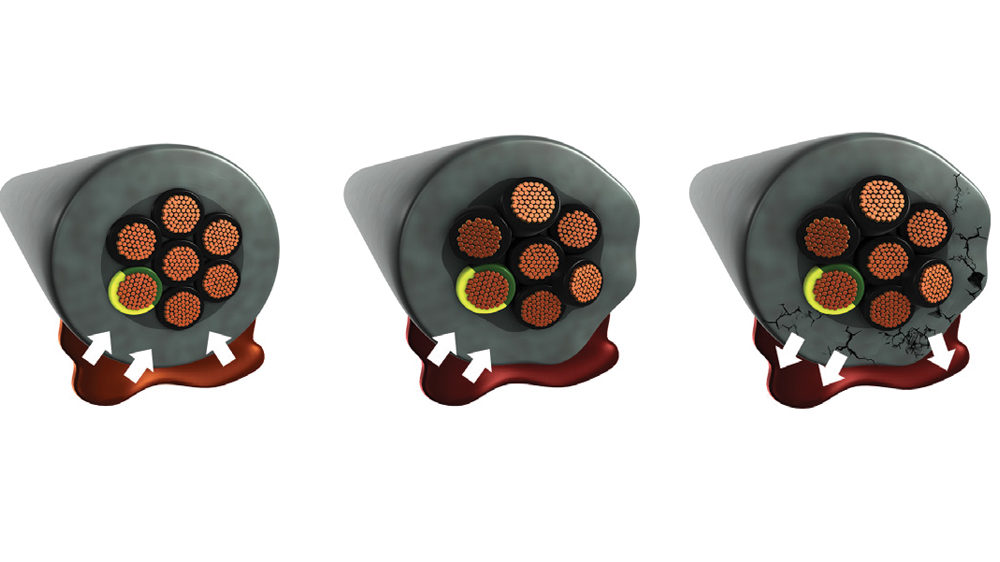

Companies need to ensure compliance to safety regulations to keep their data safe and it begins by blending standard, safety controls onto a single platform that leverages intelligent, machine safety designs. Such controls help guarantee productivity as safety-related issues can be spotted in real time and the concerned operators can be alerted promptly to resolve issues while minimising downtime. The second aspect, albeit a connected one, is to ensure that the data is safe. While establishing a wholly connected enterprise, the idea is to make data available at all levels of production to sales. It is also imperative that the data is kept safe and secure. Control systems need to be connected to make information accessible and actionable, while connectivity ensures alerts in case of a breach.

The third element for a connected technology platform lies in simplifying the infrastructure for networks, which ultimately cut risks of integration. Solutions like a single open Ethernet/IP network or a control and information platform can save crucial time and confusions through a simplified infrastructure. They also pave the way for real-time diagnostics and analysis, which formulates the fourth element of a connected enterprise. Devices like sensors help collate data and deliver real-time data for predictive analysis, which is now crucial for a company’s strategy ahead. They help minimise repair and troubleshooting times, while allowing organisations to monitor critical parameters that can avoid issues. The fifth element that is imperative to establishing a well-functioning and connected enterprise is boosting operational efficiency through design tools that help cut system complexity and fasten system design, commission and installation.

The complete connected enterprise

For companies to re-establish themselves as a connected enterprise, the plethora of steps needed to be taken may be jarring, just to strategise and think about. It is to ease this transformation for companies that Tata Technologies offers Connected Enterprise solutions that include services for Digital Transformation, Extended Manufacturing Solutions, Data Intelligence, Customer Experience Management (CXM), Supply Chain Management (SCM) – most of which are integrated to aid the transformation journey in the enterprise. They set the stage for a company to gain that competitive edge in the market and to ensure that their vision to become a digital company becomes a reality.

While the industry sets a digital, connected enterprise as a norm across businesses, another factor that would propel the transformation faster is regulatory intervention which sets the setting for the industry-wide revamp. Policies and regulations are needed to help create a conducive environment for companies to become smart and connected with systems which need basic telecommunication infrastructure. This infrastructure will create the first step to a future where companies could be termed as connected and eventually create an entire ecosystem that would boost the growth of an economy and would lead to better standards of living. It would help create an industry that lives by the digital revolution and heralds innovation to boost overall economic competitiveness.

It is, thereby, imperative to not just make digitalisation and connected enterprises as individual efforts by companies but a collaborated one for a bigger cause.

Authored by:

Geena Binoy, Vice President – Connected Enterprise IT Solutions, Tata Technologies

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi