Shot blasting process for any surface

July 13, 2018 6:27 pm

Quality Spares Centre is one of the few companies to offer a vast and qualitative range of industrial steel abrasive products. Owing to the dexterous team, state-of-the-art infrastructure and the quality, the company accomplished in attaining the maximum satisfaction and trust of its esteemed clients.

Process of shot blasting

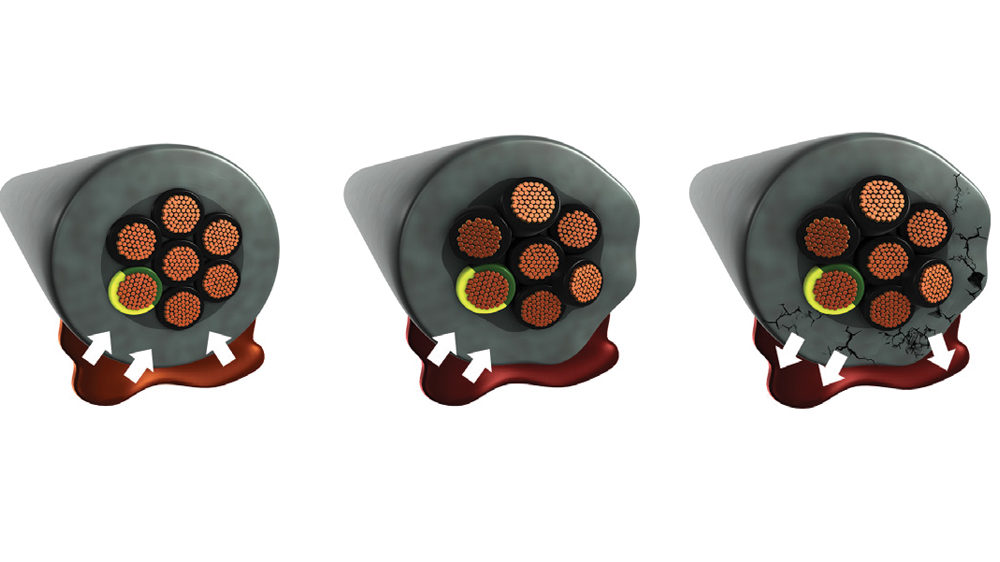

Shot blasting is a fabulous process to give the desired finish to critical components than using different technology. It still remains one of the lesser known processes but an important one. It is a process that is normally done on concrete or metal surfaces. While similar to a sandblasting process, shot blasting is very much different in both the way; it is executed and effective. Shot blasting is used in almost every industry that uses metal including aerospace, automotive, construction, foundry, ship-building, rail, etc.

Benefits of shot blasting over conventional sand blasting

Steel beads are shot inside a machine onto the component to clean it in an industrial manner. To begin, one needs to load the machine with the beads or shot pellets. The beads blast off any stains embedded on the components that can’t be removed through normal cleaning methods.

Application

• Roughening surfaces in preparation for thermal spraying, painting, bonding or other coating operations

• Removing rust, scale, sand or paint

• Providing a matte surface finish

• Removing flash from molded components

• Cosmetic surface enhancement or etching

Shot blasting machines

Shot blasting ensures that the steel is cleaned to bare white metal giving the best possible surface essential for the application.

Shot blasting machines are available in a variety of different types and sizes. The great thing about shot blasting is that there is hardly any dust or clean-up involved in the process. It is not only done to help finish the component but to prepare it as well.

Achievement

Being unaware, here-in-before the auto components industries have been using the sand blasting medium for surface treatment of components such as nuts, bolts, screws, clutch plates etc. etc. But by evolving a new technique the company has accomplished this function by using shot blasting process in place of sand blasting i.e. completely automatic component feeding in place of the conventional manual feeding.

Authored by:

Rajan Sikka

Proprietor

Quality Spares Centre

www.shotblastingmachine.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi