Make in India: A win-win for all stakeholders

July 5, 2016 5:27 pm

To be a truly factory hub for the world, India needs to ease the complicated tax structures.Ameer A Munaff, Managing Director, FEIN Power Tools India

Foreign direct investment (FDI) into the country has been increased by 37 per cent to US$ 39.32 billion during 2015. Ameer A Munaff, Managing Director, FEIN Power Tools India Pvt Ltd believes that the main reason for the sudden surge in the foreign direct investment that can directly attribute to “Make in India” initiative is it offers a win-win state for all stakeholders.

Impacts of “Make in India”India launched “Make in India” program to create employment opportunities for it’s approximately 60 per cent youth of the total 1.25 billion population who are below 30 years of age. India’s GDP has been growing at about 7 per cent a year over the past one decade. The trade deficit has been growing steadily reaching 5.6 per cent of GDP in the fiscal year ending March 2016. Though the numbers look promising, India mostly exports products that are less trade efficient like rice, cotton, diamonds, garments, etc. meaning most of India’s manufacturing and exports, contribute a small fraction of the global trading commodities. The “Make in India” campaign was designed to push the manufacturing sector from the present 16 per cent of GDP to 25 per cent of GDP. The concept isn’t totally ripe yet to reap the benefits, although there is a sense of optimism that it can trigger manufacturing driven growth.

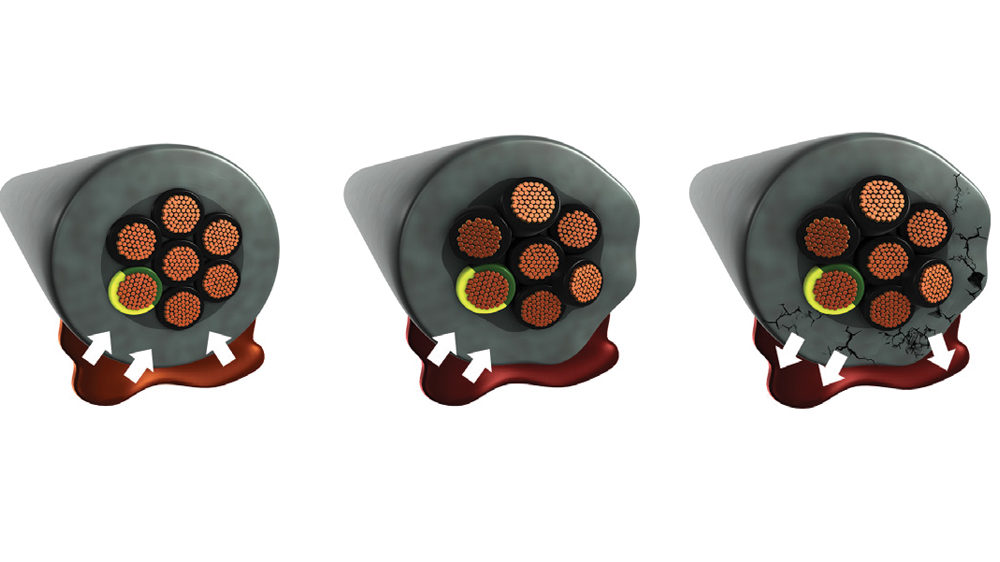

FEIN being one of the premium power tool manufacturers offering solution to the needs in metal, interior and automotive industries of all sizes, has started seeing the change in terms of the demand. As the industries are growing on a positive note, the demand has risen two-fold this quarter when compared to the last year.

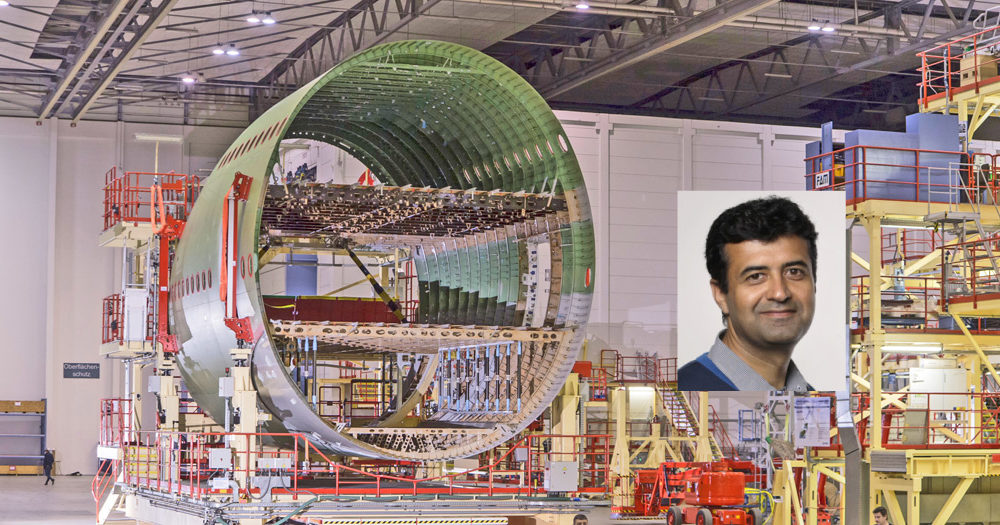

“Make in India” to reduce imports, create jobs “Make in India” focuses on 25 sectors including defence manufacturing, automotive and components, aviation, machinery, etc. where several reforms have been initiated to boost manufacturing. Among these, electronics, defence manufacturing and aviation sectors can substantially reduce India’s major imports and sectors like infrastructure and agriculture are aimed at boosting domestic growth. This boost is expected to create more job opportunities.

Why all eyes are on IndiaThe main reason for the sudden surge in the foreign direct investment that can directly attribute to “Make in India” initiative is it offers a win-win state for all stakeholders. India offers cheap skilled labour to the MNC’s and they in turn offer employment for the Indian citizens. Indian government offers sops and benefits to the companies and given that India is one of the largest consumer markets, the benefits to the companies catering to Indian consumers are very high than in terms of importing. Abundant raw material resources too give a competitive edge in terms of low-cost manufacturing inputs, thereby reducing the overall cost of production. According to the latest report, Foreign Direct Investment (FDI) into the country has increased around 37 per cent after the launch of “Make in India” programme till February this year.

C. & E. FEIN GmbH invested to set up the subsidiary in India seven years back as India is a very significant and interesting market for the FEIN group. The company believes that the presence in India would strengthen its position globally and highlights the strategic importance of the Indian market while writing the next chapter in its success story as an inventor of reliable power tools and a flourishing international business. FEIN’s professional tools will bring a huge difference in the Indian market by way of giving cost effective and efficient solutions for the toughest industrial applications for day-to-day work. FEIN is responding to the growing significance of the Indian market by forming its own subsidiary here. This set up is very important to strengthen its position globally and FEIN India would also be a hub for all SAARC countries for these tools which would be exported from here in future.

Beyond the roadblocksFor a bright future, India must proceed steadily down the path of economic reform, development and modernisation. To be a truly factory hub for the world, India needs to ease the complicated tax structures. India needs to build corridors across the length and breadth of the country to boost manufacturing and showcase India as a global manufacturing destination of the world.

In terms of development, skilled manpower should be in constant supply to meet the rising demands. This can be done by opening more industrial training institutes and skill development centres across the country. FEIN India has stepped forward in this regard as part of CSR activity to train and certify students of economically challenged section to help them industry ready. And those who perform outstanding will be hired as trainees for a career with FEIN India.

Simplifying the process of doing business is the key to invite investors and boost manufacturing. Like investing, a proper and easy exit option is mandatory for the stake holders. Though India has moved up 12 places in the World Bank’s ease of doing business index in the last one year, more transparency is expected by the investors.

Making big strides with “Make in India”FEIN being the inventors of power tools with roots and manufacturing unit in Germany decided to take the first step towards being a part of “Make in India” initiative by setting up a design and testing centre in India. The main reason being Indian SMEs has many characteristics that are similar to their counterparts in Germany. The second step will be to work on sourcing components, precision items etc. which would finally lead to a situation where these volume products will fit for future manufacturing facilities that will be established.

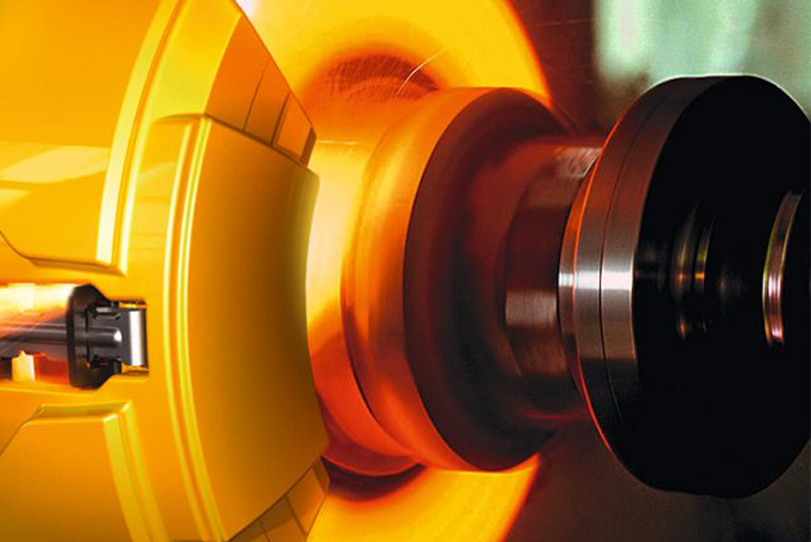

About FEINThe world’s first power tool was invented by C. & E. Fein GmbH. Wilhelm Emil Fein founded the company in 1867. In 1895, FEIN invented the electric hand drill, the first-ever power tool. Today this long-standing company is a world-renowned power tool manufacturer. The German manufacturer of premium products develops and produces application solutions for the metal working, interior outfitting and automotive sectors and is the specialist for professional and extremely reliable power tools for industry and manual trades. FEIN holds more than 800 active industrial property rights, including around 500 patents and patent applications. FEIN markets its products through 61 representations including 19 international subsidiaries world-wide. For over 149 years, FEIN has been synonymous with application solutions and premium quality.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi