A cut above for the manufacturing industry

August 7, 2019 3:24 pm

The cutting and the milling industry has witnessed a disciplined growth with increase in demands at national as well as at an international level. Here, is an industry analysis evaluating the growth, design and future of cutting and milling tools.

Cutting tool industry in India is growing and changing every day. Over the years, the tool manufacturers have upgraded their basic tool materials and its capabilities. On the other hand, evolving needs of the customers have led cutting tools vendors to include innovative and industry-specific solutions.

Divya Purohit, Business Line Manager, Atlas Copco India Ltd. says, “We have been witnessing a huge demand of energy saving machineries from our customers, and we as a manufacturer, are making persistent attempts to meet their demands by bringing them a product that guzzles possible less power.” The CNC and VMC machine manufacturing require wide compressor solutions. By catering to their demands by providing compressors, compatible to their machineries, Purohit says that the machines they manufacture, will adapt the required capricious note that falls into the typical cutting tool technology, further saving energy by reducing the average consumption of customers. However, many vendors are looking forward to have new tie-ups to widen their services into this segment.

Gautam K. Ahuja, Managing Director, Dormer Tools India Pvt. Ltd, is of the opinion that that the growth in cutting tools will come from the aerospace industry. Though the industry is its nascent stage in India, they offer significant potential. Other sectors the Indian government has opened to the private sector are railway and defense, which will also support growth in these areas. Ahuja says, “The cutting tool industry is ready for the challenge these sectors bring and creating the products fit for the future. New product development will focus on providing customers with high tool life and productivity.” All segments, however, are subject to market conditions. The GDP in India is low, mainly due to the general elections, coupled with a global slowdown.

The industry is showing disciplined growth with increase in demands at national as well as at an international level. I see the automotive, heavy and light engineering sectors as the key drivers to the growth of cutting industry as India is becoming a hub for major automobile and auto components manufacturers. As a part of initiative taken by the government for “Make in India”, a lot of investments are done in the country’s power generating capacity, railway networks and increase in the production of defense goods and aerospace; significantly contributes towards the rise in demand for cutting tool industries in India. Even the growth in machine tool industries can result into the growth of cutting tool industry in India.

Maulik Patel, Executive Director, SLTL Group says, “The government’s vision towards increasing the contribution of manufacturing industry into the country’s GDP, will result into increase in overall demand of cutting tools. As an agile, and competitive market, I believe the Indian cutting tool industry is going to perform strong in national as well as in international market.”

R&D undertaken while determining cutting tool applications

R&D is a key difference maker that helps any company to become a leader or pioneer in the entire industry. The operations and requirements differentiates the key focus areas of R&D for each and every industry as well as the companies. R&D at any companies or in any industry is done mainly to increase effectiveness and working efficiency of the company and bring innovations in the products manufactured by them. Patel says, “At SLTL Group, we have a strong focus on innovations. Our in-house R&D team is always focused towards taking extensive measures to develop the new systems and bringing upgradations in the technology. Our team always look forward to bring solutions towards various industrial challenges with innovative technologies.”

Purohit’s customers are not bound just in India, but are globally too. Hence, they are said to receive quite a lot of customised requirements globally, which are met from their global engineering centre in Pune, where all the R&D is being carried out. This keeps them close to the market, particularly, to the Indian market and its changing trends. He says, “We keep upgrading the necessary changes in our CNC and VMC machines, and the required software. We ensure on meeting our customer’s prerequisite changes and delivering them the most attuned output product. Our products and solutions are edged, after taking the future needs into account, and hence ensure sustainable product for our customers.”

Futuristic cutting tool design

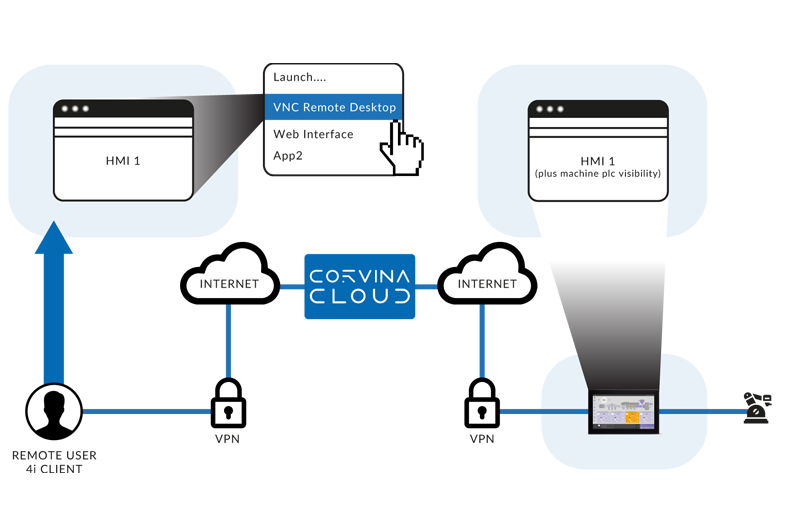

We have seen a strong growth in cutting industry in the last few years. The Indian cutting tool industries is very adaptive to grow ahead with an aim to increase the output in the existing setups with upgradation in the technologies like automations, Industry 4.0 and IoT. According to the market demands, industry can grow themselves by making an attempt to incorporate the advanced technology in their current as well as future operations.

Patel is of the opinion that due to rapid increase in automations, the futuristic technologies have always helped the industries to meet its demand and grow themselves towards the current openings in the market. He says, “We would like to grow always and bring the innovations that can help the industries become smarter.”

According to Purohit, there are two things to be considered while catering to the market, one is the generic products and the other, customers with particular demands. Their customised solutions for the customers are completely taken care by their Indian factories. He says, “While talking about the upcoming products, one of our major focus is the noise factor. For say, the piston machines, they have a heavy noise load, and, as an attempt to reduce the noise in any loading machine, one of recently launched compressors are noiseless. We found that the CNC and the VMC machine manufacturers, are keen to have out products incorporated, as an added value for the customers because of its reduced noise level. Since we have been boosting the idea of saving energy and reducing the pollution of various kinds, this is just a one step ahead for us, to reduce the amount of energy being consumed, by reducing the loud noise to almost nil.”

Selecting the right milling tool

Certain factors must be considered when selecting milling tools. Combining high cutting data with long tool life for high-performance milling cutters contribute to an increase in the productivity of manufacturing processes and to a more favorable cost structure. Manoj Sharma, Product Manager, Miranda Tools says, “Selecting a right end mill for job is most important in machining process. A high performance cutter with high cutting parameter and with long tool life contribute a lot in tools planning.”

He suggests the following major factors must be considered while selecting a tool:

• Material to cut

• Type of cutting operation as roughing/finishing/plunging/slotting

• Number of flute- 2/3/4 or 6 flute

• Specific tool dimension as diameter tolerance, length of cut, reach of tools and profile etc.

• Type of coating for more aggressive running parameter and prolonged tools life

Real cost of choosing standard tooling

Standard tooling is based upon proven technology and years of trial and error. The upmost benefits of having standard are saves time, fast delivery and availability for universal applications. With customised tooling, according to Sharma, tool manufacturers should study application at shop floor, drawings and approvals needs to be done before finalising. Once on shop floor, he suggests that it is better to go for special tooling which gives a long term benefit.

Operational safety and performance of milling cutters

Safety features to keep in mind to clean every insert seat properly during indexing, use of proper Torx Key, sufficient coolant at high pressure at the cutting edge, and using optimum parameters. Ahuja says, “Pramet cutters are balanced for operational safety. The performance of Pramet cutters is one of the best in the industry, whether it is face milling, square shoulder milling, high feed cutters etc, even at one of the highest parameters. We specialise in reducing cycle time in milling and thereby improving productivity.”

New product development will focus on providing customers with high tool life and productivity

Gautam K. Ahuja – Managing Director, Dormer Tools India Pvt. Ltd

The Indian cutting tool industries is very adaptive to grow ahead with an aim to increase the output in the existing setups with upgradation in the technologies.

Maulik Patel, Executive Director, SLTL Group

We keep upgrading the necessary changes in our CNC and VMC machines, and the required software to ensure meeting our customer’s prerequisite changes.

Divya Purohit, Business Line Manager, Atlas Copco India Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.