United Grinding setting standards in machining

March 15, 2017 12:32 pm

We do not just sell a machine because we believe selling a machine is the easiest part in the whole process – our prime target is to have a satisfied customer.

Philippe Selot, Manager Marketing – Comm, United Grinding Group AG

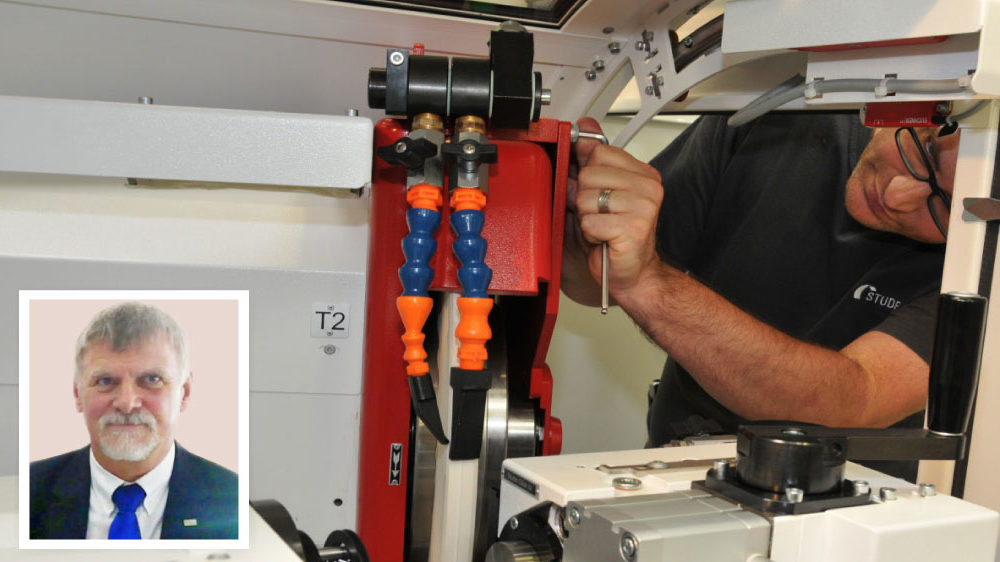

With its eight strong corporate brands viz. Mäegerle, Blohm-Jung, Studer, Schaudt-Mikrosa, & Walter-Ewag, United Grinding is creating waves in hard fine machining markets across the world. Subhajit Roy caught up with the company’s Manager Marketing – Communication Philippe Selot and President – India Operations CR Sudheendra during IMTEX 2017. Interview excerpt:

Philippe, could you give us a brief overview of your business activities in India?

Philippe: United Grinding is by far the world’s largest supplier of grinding machines. We have a 25 per cent of market share worldwide and the world’s second largest group is not even half of what United Grinding is. We have 3 brands namely Mägerle, Blohm, and Jungunder ‘Surface & Profile’ business. In the ‘Cylindrical’ business, we have Studer, Schaudt and Mikrosa brands whereas Walter and Ewag are the strong brands under the ‘tooling’ segment.

In India, we have been present for a considerable time having an office in Bengaluru for sales, services and support along with a technology centre. We provide the same quality of service that we offer in Europe.

Do you have any future plans to manufacture in India?

Philippe: No, because the volume of machines sold in India is not sufficient enough to start manufacturing in India. We have various facilities that are spread around the globe and we import the products as per the requirement.

What are the USPs of your sales and services that make United Grinding a stand out from the rest of the competitors?

Philippe: In terms of innovative, reliable, and high-end technology products, United Grinding is the world leader. We sell about 43 per cent in Western Europe, 7 per cent in Eastern Europe, 27 per cent in Asia and 23 per cent in the US. So, we are absolutely a global company with 2,300 employees around the world.

Further, we do not just sell a machine because we believe selling a machine is the easiest part in the whole process – our prime target is to have a satisfied customer. It is certainly something that we fulfil than the other competitors. We have a very professional outlook and our manpower is best trained.

Sudheendra, globally you have a market share of over 25 per cent. What is your share when it comes to Indian market?

Sudheendra: On the cylindrical grinding with our brand like Studer we have market share of around 17-18 per cent whereas in the tool side Walter has the share of 25 per cent. Brands like Mäegerle are extremely high capital intensive projects oriented and are not like the regular machines. They are basically used in aerospace and energy sectors. In India, aerospace industry is still predominantly government controlled and private players are yet to make significant mark there.

Which brand gives you greater business in the Indian market?

Sudheendra: If we look at the numbers till now, Studer and Walter are selling the maximum machines. Slowly the things are changing and brand like Schaudt which is globally popular for camshaft grinding is gathering stream.

Are you bringing any India-centric product?

Philippe: Our products are always tailored as per the applications of the customer. We have 60 per cent standard machine and 40 per cent are tailored as per the customers’ requirement. We have to adapt the machine and the application as per the customer wants. So, the concept is not India specific but application specific tailoring.

How beneficial is Industry 4.0 going to be?

Philippe: It is a natural development of technology trend. Though the entire industry is talking about Industry 4.0, we are yet to get its clear definition. As far as our business is concerned, the main target is to make our customers efficient – the machines have to be efficient and then customer will have to be benefited from the investment. Preventive maintenance, long-term reliability and zero breakdown with improved machine-to-machine and man-to-machine communication will determine the parameters of Industry 4.0 in our business domain. We are integrating variety of futuristic features in our machines in this regard.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.