Driving technologies on display at Phillips Demo Day

September 19, 2022 12:45 pm

Phillips Machine Tools India, a global supplier and manufacturer of cutting-edge technologies, establishes a technical centre in Noida to strengthen its market presence in the northern market. To commemorate the opening of the technical centre, the company hosted a Demo Day here during the fourth week of August 2022. This exhibition highlighted various technologies such as milling, turning, grinding, EDM, Additive Manufacturing, automation, and metal forming.

At this event, we displayed an industrial Grade Printer. This X7 carbon fibre 3D printer fundamentally enables engineers and designers to improve manufacturing operations at light speed. It is used to print industrial production parts. It has many new features and benefits in terms of improving the speed, more materials, and online inspection also. The blacksmith software is AI-based, which is the best in industrial grade printers. It also enables the customer to match the output with the original design, which is crucial for the customer to ensure the accuracy of the parts. The Markforged is known for strength in the 3D printed parts, which is one of the best in class in the 3D printing category. In terms of materials, we are known for composite materials. One of the base materials is onyx, which is a mix of Nylon and Carbon fibre. We were delighted to meet the customers looking to start a new journey of adopting disruptive manufacturing, technologies, and 3D printing.

People are looking into new ways of Digital Manufacturing. The best part is they are seeing that these are machines which are going to help them to improve or to add value to their customer base as well. By adding up this technology, their portfolio will allow them to enhance their return on investment to help them improve overall environmental sustainability. It helps them to overcome the challenges of the supply chain and to overcome the challenges of skilled workforce shortage as well. And on top of that, it adds value to their customers. It is also remarkable for them to see additive and subtractive under one roof.

As event partners, the company partnered with Mastercam India, Tungaloy India, REGO-FIX Group, Ahire Machine Tools, and MMC Hardmetal India for this Demo Day edition in Noida. Each of the partners had run special promotions for Demo Day attendees. Continue reading about the comments and trends for solutions, products and automation scenarios in the changing environment.

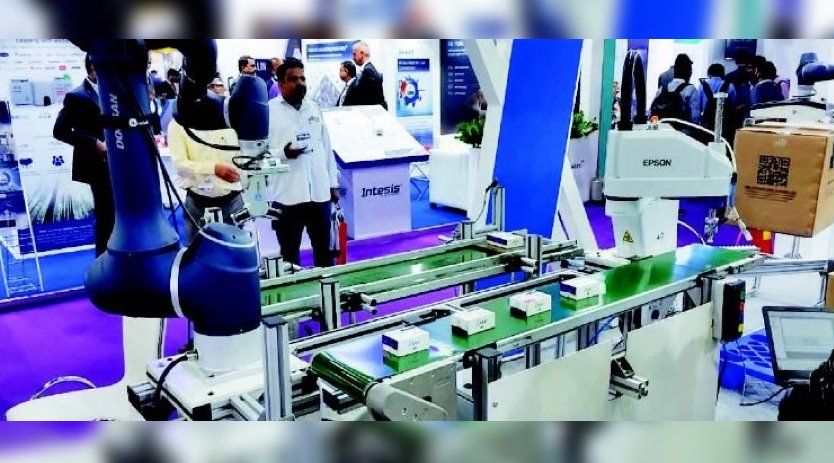

Businesses are now attempting to transition to Industry 4.0, a major robotic trend. We, an automation company, offer a variety of industry 4.0 solutions. We demonstrated collaborative robots, palletizing solutions, vision-based pick and place applications, etc. Some are IoT applications, and some soldering solutions are also suitable for dispensing applications. Our customers come from the electronic manufacturing solutions, FMCG, and automobile industries so you can work anywhere a robot can go. We do a lot of work with refractory ceramics, abrasive industries, food, and similar processes for our IoT solutions and other automation work. Our robots and robotic solutions are prevalent. Many businesses are now attempting to transition to Industry 4.0 and make greater use of technology.

Regarding robotic trends, collaborative robots are a new thing that has emerged in which people, humans, and robots work together. The industry 4.0 implementation is a major robotic trend where people want real-time information. Predictive maintenance is essential. We are just getting started. People are catching up; we also have a predictive maintenance solution in which we sense vibration for motors and then use predictive analytics to see if the vibration changes over time from a baseline pattern. So if this changes, the system can automatically notify someone, “I see a different vibration pattern, and it is now time for you to go check it before it begins to fail.”

We displayed new generation cutters and Solid carbide Tools at this event. Such as WJX cutter: High feed milling cutter having double-sided inserts (6 Corners); WSF406W: Face milling cutter for cast iron machining with an adjustable runout system; WWX400: Shoulder mill having double-sided insert (6 corners); VPX: Multifunctional cutter with high-efficiency machining and it has tangential mounting inserts; VQ series End mills: End mill series for difficult to cut material; Alimaster End mills: Highly efficient multi-functional for Aluminium alloys machining; MHS Drill: Solid carbide drill for Die & mould machining and Thread end mill: For machining Precision thread in a range of material including hardened steels up to 65HRC. In respect of indexable milling and drilling solutions from industry 4.0, in recent times, Mitsubishi Japan has developed new indexable milling solutions like WSX445, WJX, ASPX, WSF406W, FMAX, WWX400 and VPX milling cutters, besides complete new range in drilling like centring and chamfering drills, Flat bottom drills, high-efficiency drilling for Aluminium alloys. If we talk about industries, we deal in all kinds of industries like Automotive, Aerospace, Die & Mould, Medical, Oil & Gas and Energy. And, for aerospace, we have a wide range of products in our basket like exchangeable Head end mills for machining Aluminium alloys, Multi-functional cutters for highly efficient milling. Also available are round insert cutters, vibration-controlled end mills to cut for Difficult to cut materials, and VFX cutters for Titanium Alloy milling.

Our new generation products, will help customers improve their productivity and reduce cycle time and cost per component. With the new industrial revolution, there is advancement in metal cutting technology.

We are focussed on being a “Full Line Supplier’ to our customers, and our product line is designed as per need. We have a range of standard and customised solutions for Turning, Grooving, Drilling and Milling, along with a range of basic adaptors to suit all types of machines. Along with the products, we also offer services to provide a full solution to the customer. We have a technical team which works on the proposal for new components to offer complete solutions to our esteemed customers. We also participate in productivity enhancement exercises to reduce the cycle time of the existing components. Customers can contact our local team for such activities. The Demo Day at Phillips’ event allowed us to demonstrate highly productive solutions on the latest in machine tools. Customers can witness the cutting and get a feel of the product to implement on their shop floors. We take feedback from each segment for updating our product line based on the needs of the specific industry segments. This ensures that we offer the right solution every time. We have specialised solutions for all segments like Automotive, Die and Mold, Aerospace, general engineering, medical and the power sector. We can offer a complete solution for any component from these specific industries.

Aerospace has particular requirements due to the material being used. We need the right grade and geometry to offer the best solution in this industry. We have the AH8000 series of grades designed for machining superalloys, which is very popular in the Aerospace industry worldwide. We have unique turning holders, “Tung-Tun Jet”, which increases the tool life drastically. Altogether, we have the complete product basket available for the Aerospace segment.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi