NORD Drivesystems offers the next generation of efficient energy-saving motors

July 31, 2023 1:45 pm

According to Amit Deokule, Director – Sales & Marketing, NORD Drivesystems, implementing suitable drive systems based on the NORD ECO BOX’s findings, one can effectively reduce CO₂ emissions, lower energy usage, and optimise various costs related to administration, maintenance, and wear.

What latest advancements have taken place in the drive systems for energy efficiency?

The NORD ECO BOX offers a comprehensive understanding of energy consumption in your system, enabling the identification of opportunities to minimise energy requirements. Its advantages lie in providing measurable data, precise analysis, and the ability to utilise potential energy savings. This innovative tool allows for detailed measurement of energy consumption in your drive system or individual drives, providing valuable insights into consumption patterns and identifying areas for potential savings.

The NORD ECO BOX breaks down consumption, utilisation, and total cost of ownership (TCO) values through thorough data analysis, allowing for informed comparisons with other drive systems. This facilitates environmentally and economically responsible decision-making.

By implementing suitable drive systems based on the NORD ECO BOX’s findings, one can effectively reduce CO₂ emissions, lower energy usage, and optimise various administration, maintenance, and wear costs. Furthermore, lowering variants offers opportunities to streamline production, logistics, storage, and service processes, improving efficiency.

Please discuss new technology trends for motors or components for transmission systems.

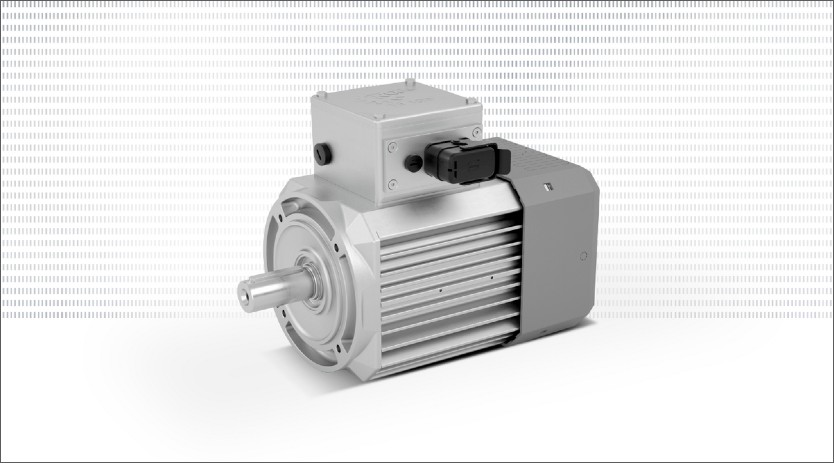

NORD Drivesystems introduces the next generation of efficient energy-saving motors. The IE5+ synchronous motor substantially increases energy efficiency, complementing the standardised geared motor variants of the LogiDrive system and effectively reducing the need for multiple variants. Ideal for intralogistics applications, this latest generation permanent magnet synchronous motor surpasses the efficiency of the current IE4 series with significantly lower losses.

Its unventilated smooth design allows it to maintain high efficiency that, at times, is significantly above efficiency class IE5 across a wide torque range, making it particularly well-suited for operation in partial load conditions.

Further, in the context of increasing demand trends, the expanding Indian market in various sectors presents significant opportunities for automation and machine tools. Among these industries, Intralogistics stands out with a tremendous demand for automation in areas such as warehousing and airports.

How do you evaluate Industry 4.0/5.0 role in improving automotive production?

In Industry 4.0, the conditions of machines are monitored, and a broader database is analysed using intelligent algorithms. This is made possible through the Internet, cloud solutions, and enhanced data bandwidth. As a result, predictive maintenance becomes feasible, allowing potential drive damages to be detected based on evaluated operating parameters before they occur. Additionally, drive units can form intelligent groups and communicate with each other, enabling independent problem-solving in case of issues in conveyor systems (e.g., alleviating congestion, opening bypass routes). This global networking and interaction give rise to the Industrial Internet of Things (IIoT). The ultimate goal of Industry 4.0 is to achieve flexible, modular, and self-organising production that coordinates processes decentrally and autonomously.

· The NORD drive electronics feature an integrated PLC, enabling all drive units to operate autonomously by locally pre-processing data and communicating externally. Furthermore, they can perform process, and movement controls decentrally, effectively reducing the central control system’s workload.

· NORD Drivesystems’ drive units can control actuators in conveyor systems or production plants through their analogue and digital input interfaces, allowing intentional manipulation of processes. These drive units can receive, process, and transmit analogue and digital sensor signals and data from internal and external sources (e.g., photocell barriers, temperature sensors, or vibration sensors) via the inverter PLC’s input interfaces.

· NORD Drivesystems’ drive electronics come equipped with integrated interfaces compatible with all common field bus types, enabling seamless communication with various automation environments. This facilitates internal or global networking within the Industrial Internet of Things (IIoT) and allows connection to cloud solutions, unlocking the full potential of Industry 4.0.

What primary advantage is available with the design and 3D printing of parts and accessories?

The primary benefit of designing and 3D printing parts and accessories lies in the simplified and accelerated manufacturing process, reducing waste and ease of production.

What demand trends in the automation and machine tool segments influence the gears and motors market?

With the rapid growth of Indian industries, there is a significant opportunity for the gears and motors market. NORD Drivesystems, as a leading drive technology company, caters to various industry sectors worldwide with its comprehensive solutions.

NORD Drivesystems offer extensive application knowledge and technical support, providing complete drive solutions from a single source. Their global presence ensures strong service capabilities, and their products are known for their high quality, reliability, and long service life. NORD Drivesystems’ wide range of products adheres to recognised international standards, making them a reliable choice for industries seeking top-notch drive technology solutions.

What automation technology trends are occurring in the gear, Motors and transmission segment?

In the current landscape, automation technology has become indispensable across various industries. The demand for gearboxes, motors, and electronics is consistently increasing due to the rise of automated conveyors, storage systems, airports with advanced baggage handling, automated car parking systems, and many other applications. NORD is a trustworthy and skilled partner to its customers, offering custom-made, high-efficiency drive solutions and extensive expertise in various applications and industries.

In essence, our motto is “Our solution. Your success.” We are dedicated to providing solutions that lead to your success and growth.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi