The future of laser cutting

November 4, 2020 11:33 am

Advanced laser cutting machines are in high demand as they work with high precision and very low wastage. Here’s an exclusive analysis on the laser cutting machine market in India.

– Subhajit Roy, Executive Editor

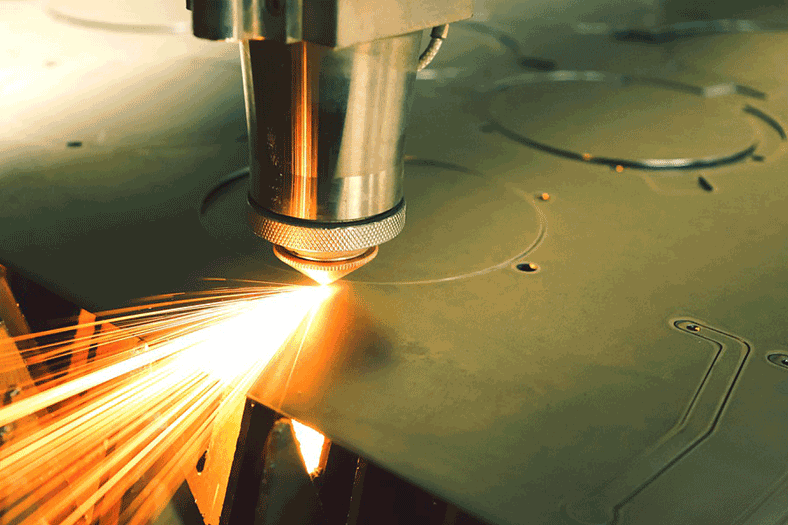

Laser cutting is now one of the most widely used manufacturing processes in the world – whether it is aerospace, automotive, electronics, semiconductor or medical equipment, laser cutting offers a huge range of benefits and uses. Laser cutting machines are increasingly being used for adding precision in cutting, engraving and even welding. Further, laser cutting offers substantial benefits to the design for manufacturing process that helps products reach market more quickly and with less cost.

According to industry experts, laser cutting technologies are beneficial as they consume low energy and have high efficiency. The quality and accuracies provided by laser cutting technologies are much better than conventional cutting technologies.

As per a research report by DataM Intelligence Analysis, the global laser cutting machine market is expected to grow at a CAGR of 9.5 percent during 2020-2027. “The rise in automation in manufacturing industries owing to the demand for high-quality products all around the world is anticipated to drive the market for Laser cutting machine in the forecast period,” the report said.

“The laser cutting technology has huge potential and is about to grow exponentially year on year. There is a big market for that. Also, as the manufacturing sector in India going to see a revival and the main motto of the country is ‘Vocal to Local’, we expect demand for laser cutting machines to grow. Today many small entrepreneurs and manufacturers are adopting advanced laser cutting machines to improve their practices,” said Dr. Arvind Patel, Founder Director, SLTL Group – Sahajanand Laser Technology Ltd. while sharing his views during an interactive session on ‘The future of laser cutting’ conducted by OEM Update recently.

Dr. Patel also represented Indian Machine Tool Manufacturers’ Association (IMTMA) at the session. He informs that the industry as well as IMTMA is taking many initiatives to deal with illegal imports.

Commenting on the preparedness of the Indian laser cutting machine manufacturers to meet the international quality, Maulik Patel, Executive Director & International Business Development, SLTL Group – Sahajanand Laser Technology Ltd. said, “The new policies being framed by the government are all favouring to manufacturing in India. Looking at the long-term perspective, as the growth is going to happen, being an Indian company we feel that the sheet metal industry is poised to grow. At the same time, we need to make sure that we have to conquer in global markets and not only in Indian market. And when it comes to the global markets, we have to meet global standards – the quality level of each and every product has to be of that level. So, Indian manufacturers are definitely poised for exponential growth, not only in India, but in global markets.”

Challenges

Highlighting the challenges for the Indian laser cutting machines manufacturers, Utkarsh Landekar, Head – Laser Business & Exports, Messer Cutting Systems India Pvt Ltd said, “The primary challenge what we are facing is the pricing of laser power sources. Compared to our neighbouring countries (like China), prices offered by the laser power source manufacturers in India are higher. As a matter of fact, power sources being imported from Europe and Japan are a bit expensive. Though the local power source manufacturers are sourcing the solutions at a very low price, the question is of the reliability because comparatively they are new in the market. So that is a primary challenge.”

He adds, “The second challenge is the awareness of the laser safety. Machineries which are coming at a cheaper price are not safe and the safety awareness is too low. We are trying a lot to create awareness, but somehow many users do not understand its importance. So that’s why the growth of laser cutting machines industry is not at so fast rate.”

Improperly used laser devices are potentially dangerous. It can cause a range of health issues – from mild skin burns to irreversible injury to the skin and eye. Thus, Amarkant Jha, CGM – Technical Center at Amada (India) Pvt. Ltd. also believes that safety remains the prime concern. He said, “Even at the exhibition centers, almost 90 percent of machineries come without their enclosures and laser being hazardous can cause severe damage to human eyes as well as skin. The government should think about how to stop use of laser cutting machines that are unsafe for the operators because there is a long term effect of laser radiation to the human health. I think we should not play with the life of human beings just to get a machine at lower price.”

Conclusion

Reports suggest that the global laser cutting machine market is primarily driven by the high rise in automation owing to the demand for standard quality products all around the world. Explaining three factors that will drive the growth of laser cutting machines market in India, Maulik said, “Firstly, the growth and development of SMEs and MSMEs sector will be the major growth driver. Secondly, automation and thirdly digitalization are the key factors driving the growth of the laser cutting machines market.”

Today, manufacturers across sectors are investing in automation of laser cutting owing to the minimal downtime and energy conservation needs. Laser cutting machines manufacturers are increasingly integrating Internet of Things (IoT), Artificial Intelligence (AI) and artificial neural network (ANN) to make their machines efficient and intelligent. Thus, the future of laser cutting lies in automation.

The laser cutting technology has huge potential and is about to grow exponentially year on year. There is a big market for that.

Dr. Arvind Patel, Founder Director, SLTL Group

Firstly, the growth and development of SMEs and MSMEs sector will be the major growth driver. Secondly, automation and thirdly digitalization are the key factors driving the growth of the laser cutting machines market.

Maulik Patel, Executive Director & International Business Development, SLTL Group

The government should think about how to stop use of laser cutting machines that are unsafe for the operators because there is a long term effect of laser radiation to the human health.

Amarkant Jha, CGM – Technical Center, Amada (India) Pvt. Ltd.

The primary challenge what we are facing is the pricing of laser power sources. Compared to our neighbouring countries (like China), prices offered by the laser power source manufacturers in India are higher.

Utkarsh Landekar, Head – Laser Business & Exports, Messer Cutting Systems India Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi