AI and 3D Printing Predominating The Automotive Industry

July 9, 2019 3:32 pm

Automobiles are early adopters of technology trends as the industry is consumer centric, technology craving yet at the other side of the spectrum very cost sensitive. Here, industry experts discuss how AI and 3D Printing is causing waves of changes in the automotive industry

All OEMs focus on enhancing customer value and put a special focus on research and development, which enables them to stand out as innovators and technology leaders in a highly competitive market.

Type of artificial intelligence technologies in vehicle

Artificial intelligence in various forms has become evident in automobiles globally. Ninad Deshpande, Head – Marketing, B&R Industrial Automation Pvt Ltd informs, “Voice assistance and autonomous vehicles is being a few notable in early adoptions. Real-time tracking of weather forecasts for assisting the driver with adapting the nature of driving have been explored and considered. This has a large impact in autonomous vehicles too as this assistance serves as a great input for managing driving.”

Further, Deshpande adds that connectivity with parking spaces in real-time enables a large reduction in time and fuel consumption, while searching for a parking spot. This acts a useful tool in large malls, theatres or sports arenas. Real time traffic or accident assistance, provides alternate routes for vehicles to reduce travel time, which is especially essential aspect for ambulance. In addition, there are many more avenues, which will be dominated by AI in near future.

AI is reinventing 3D Design

In India, the main motives of automotive sector are complete assembly of automotive parts by the OEMs, practically the most important part, and further assembly of entire supply chain. AI and related technologies are just multiples of it. The increased lead of the previous assembly has to be rightly defined with time, place, where it gathers the other sub-assemblies’.

Sharadi Babu, Chief Executive Officer, AXISCADES confirms, “In AI, we do the complete simulations of an assembly line to realise and understand its performance pattern. Moreover, you are aware of the installation process and the parts being used, so as to ensure in stocking those parts for near availability. Also, the entire process of installation and workflow is monitored by the Intelligence process. The AI platform is being delivered to ensure timely availability or the immediate requirement of system parts, including the pre-assembly and post assembly activities.”

Design of vehicles on paper is not prehistoric but there are now tools available, which assist the designers in understanding the design feasibility. This reduces rework and improves vehicle performance. Simulation tools enable testing of vehicle in various environments and terrains. This provides a clear understanding of dynamics, balance even before the vehicle is manufactured. Deshpande says, “These techniques also help in reducing the time-to-market for a vehicle as well as saves enormous costs. Similar design and simulation techniques are being deployed in manufacturing processes, which helps in reducing downtime, increases machine availability, increase time-to-market. A seamless integration between the design tools and automation environment further reduces the programming effort during execution.”

Hurdles in AI

Higher costs of implementation, inability of major consumers to pay premium for add-on features provided are the biggest challenges for Indian OEMs to adopt and implement such advanced technology function in their automobiles. However, according to Deshpande, “This is owing to the fact that majority buyers are cost conscious and not technology or feature oriented. This will change in due course, however, it would take time to change, as it needs a change in buyer’s perspective.”

Babu, suggest, “The AI is adopted in clearance with OEM, to match the level, and categorical adoption. The type of integration done by Daimler for commercial vehicles is different from Renault, Nissan. So, it depends on the type of vehicle and the level of configuration, as today, you can order a multiple variations of the car; low end, medium, and high end cars, as the assembly lines are same in all these variants.”

AI enables one to customise their assembly line, where, only 60 – 70 per cent of the assembly line is standard and the remaining 30 per cent configuration is customised in line with the trending requirement, ensuring the workflow in every car has relevant messages and services to the warehouse along with the required components to assemble them. Shortly, various OEMs adopt various automotive, depending upon their needs the requirements. I have seen places, where highly strong assembly lines have been installed with the help of AI.

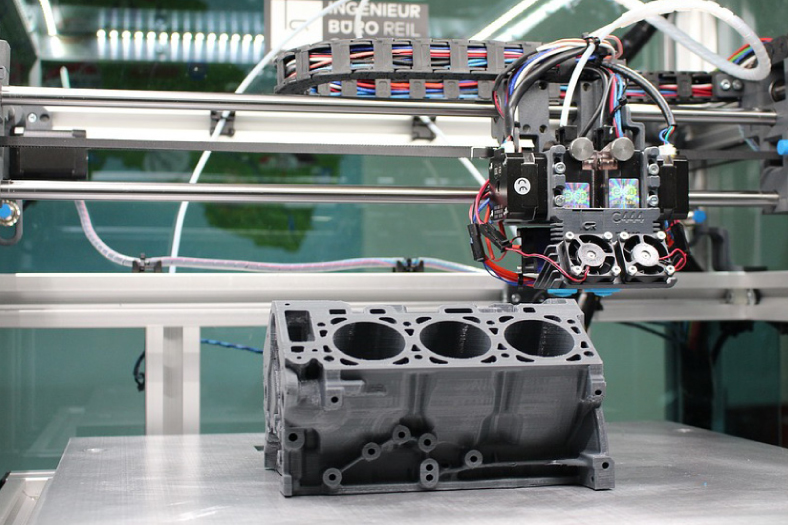

3D printing in automotive

Additive manufacturing is playing a vital role in transforming production lines in all industries. Today, 3D printed products have become a common occurrence in manufacturing from consumer goods to automotive to aerospace. Additive manufacturing provides possibilities for individualisation or customisation as well as for reducing wastage and making product manufacturing efficient and economical.

Deshpande says, “Automotive industry is dynamic with a constant focus on reducing waste, improving efficiency and quality in production and thus improving overall profitability. With 3D printed products, automotive industry will be shifting gears in the aspects of optimisation, scalability and flexibility.”

With the possibility of individualised components able to be manufactured in small batches in automobiles, it makes it possible for manufacturing plants to have a single line for manufacturing not only different variants, but also different models. Deshpande assures, “This would eventually provide for better space utilisation, reduce operational costs. Coupling these 3D printed products with intelligent product transport technologies such as the B&R ACOPO strak and integrated vision are expected to revolutionise production lines, especially for the auto component and ancillary industry. These technologies are game changing from the point of view of the working of a production line. A seamless integration, between additive manufacturing, adaptive manufacturing and integrated machine vision will play a crucial role in revolutionising production lines in the near future.”

3D printing catering to the aftermarket

3D printing is an absolutely different application, with a different perspective, and it today is a predominantly used for prototyping. They are said to be best fit in certain areas, it is yet to be meet the requirements of the industry in terms of real application. Since 3D printing involves both, design and manufacturing is a different aspect of design and manufacturing, where an assembly or a component is completely resigned on a system.

Babu states, “We have executed several projects, by redesigning fuel injection pump, hydraulic manifold among others, moreover, 3D printing have eased the assembling process by cutting down the requirement of 30 parts, to almost 6. Still the composition of material and purchasing the adhesives, laser, must comply with 3D printing standards to use them in an extended market. Predominantly, hydraulics used in block manifolds is delivered in 3D printing and in several automotives.”

Usually, aftermarket and spares for automotive parts is a major market, repair market especially for automobiles is enormous. This is a market additive manufacturing, which is being added into the aftermarket, for providing value added services to consumers.

Apart from these spares especially for replacements in case of damage or fault, there is a budding market for customised components where consumers are also willing to pay a premium. Individualised products provide a unique aspects to the automobile may it be for dashboards, gear shifts, driving wheel, bumpers, car spoilers, headlamps or any other aspect of the car exterior making the automobile either more appealing, sporty or unique. Deshpande, concludes, “In addition, there are many other components internally, which would be then made to order based on the customer needs especially for those model, which are no longer manufactured and spares supported by OEMs. In my opinion, this is just the start for the entry in this market segment for 3D printed components. 3D printed part owing to the vast benefits over the subtractive manufacturing of components will gain traction in automobile making the manufacturing and after sales service and upgrades cost-effective as well as customised.”

With 3D printed products, automotive industry will be shifting gears in the aspects of optimisation, scalability and flexibility

Ninad Deshpande, Head – Marketing, B&R Industrial Automation Pvt Ltd

The AI platform is being delivered to ensure timely availability or the immediate requirement of system parts

Sharadi Babu, Chief Executive Officer, AXISCADES

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi