Premium Aerotec’s ‘Force’ software module to enhance machining efficiency

January 19, 2022 12:29 pm

Aerospace experts are anticipating a significant growth, with more than 30,000 new passenger and freight aircraft required by 2033. This is going to pose immense quantitative and qualitative challenges to the existing aerospace manufacturing plants. Augsburg-based Airbus subsidiary, Premium AEROTEC, is ensuring its participation in this fiercely competitive field with the support of CGTech’s NC simulation software, VERICUT, and the application of the new Force module for ongoing operational reliability and machining efficiency.

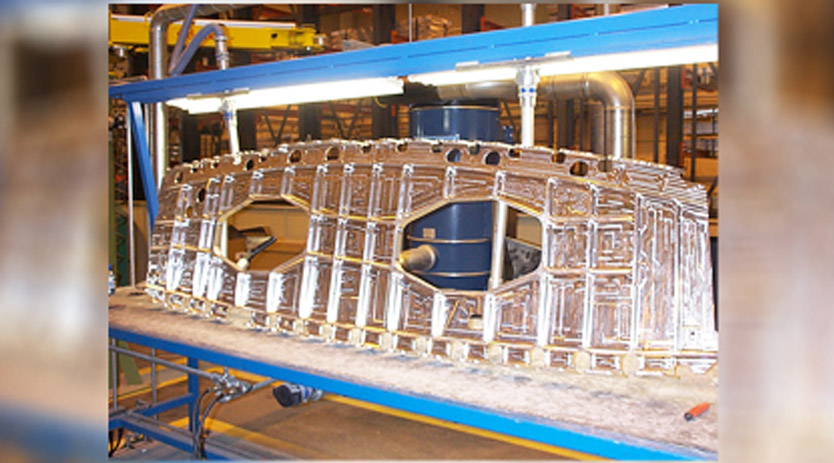

Premium AEROTEC is one of the world leaders in the development and manufacture of structures and manufacturing systems for civil and military aircraft alike. With locations in Augsburg, Bremen, Hamburg, Nordenham, Varel and Braşov (Romania), Europe’s leading aviation suppliers develop and manufacture the very latest in modern aircraft structures, from aluminium, titanium, and carbon fibre composites for the entire Airbus family. The company is a key partner in the development and production of the A350 XWB, as well providing parts for the Boeing 787 ‘Dreamliner’, the Eurofighter Typhoon, and the Airbus A400M heavylift military transport aircraft. Premium AEROTEC was established in January 2009, with the merger of the EADS plant in Augsburg with the facilities of Airbus Germany in Nordenham and Varel. Under the governance of the Airbus Group, the company’s headquarters are in Augsburg. Here, around 4,000 people are employed with the focus on the manufacture and assembly of fuselage parts and heavy-duty structural components for military and civil programmes, with the use of hybrid lightweight structures, carbon fibre technologies, infusion processes, and sandwich construction techniques.

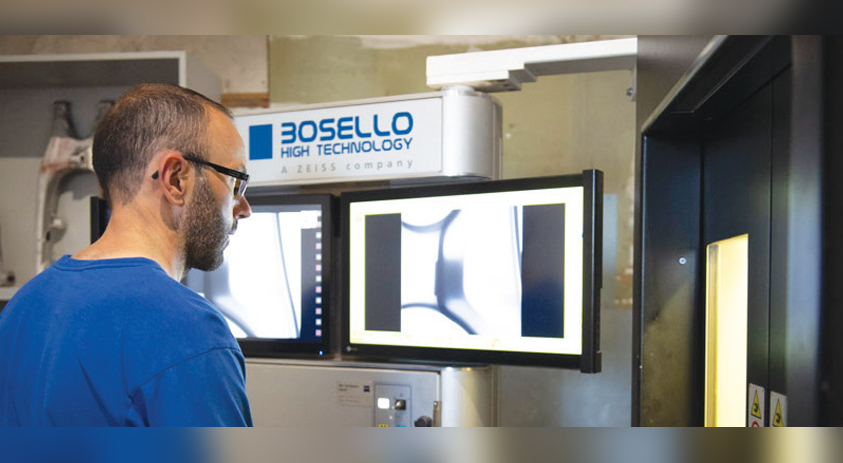

To guarantee the surface qualities and workpiece tolerances required, high performance material machining techniques are employed in Premium AEROTEC’s production area. These techniques must meet the defined quality required without scrap or elaborate repeat machining to rework components. They must also minimise the wear on the machines and cutting tools, reduce downtimes to a minimum, and be highly efficient even with complex components running in small batches; in other words, they must be fast, precise, reliable, and reproducible: without compromise. Of course, this is an environment familiar to many in the aerospace sector, where machine tool safety and security are critical to meet ongoing delivery targets. To ensure this the company has used the industry standard NC simulation software, VERICUT, as an integral element of its manufacturing processes since 1991. The fundamental aim is to avoid machine tool collisions, either with the structural components of the machine, the raw material or component, and even the fixturing systems.

VERICUT was chosen to check the NC code that generates the milling paths on the machine tools, and in 26 years of use it has more than proved its worth. “Today, there are no more prove-outs required on the machine. No NC program goes onto the machine without having been tested first in VERICUT,” explains Werner Flagner and Michael Hoffmann, under whose supervision more than 30 Premium AEROTEC personnel work with VERICUT.

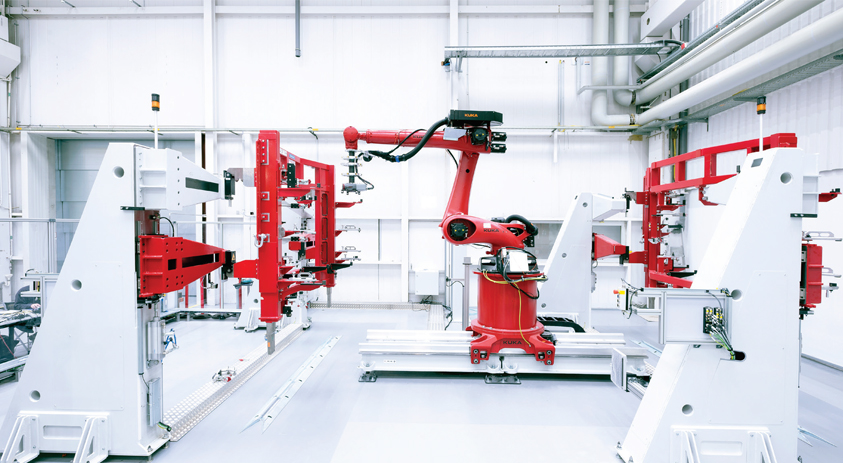

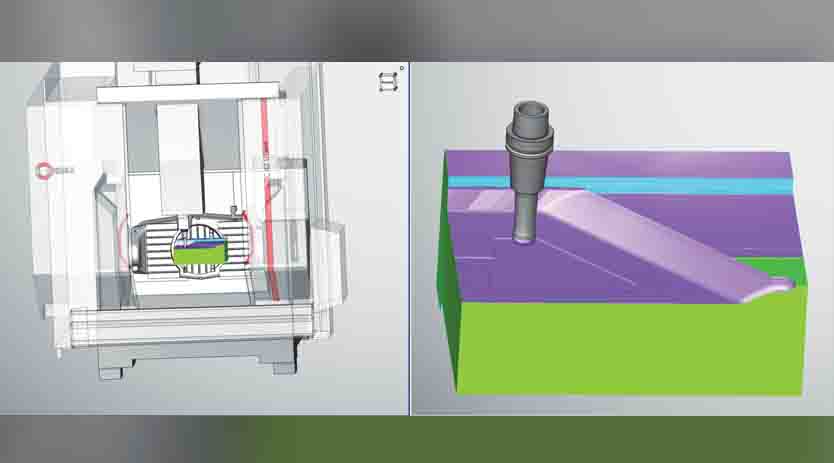

The leading independent NC simulation and optimisation software, CGTech’s VERICUT simulates the entire CNC manufacturing process, regardless of the machine, control system, and CAM systems involved, and tests the NC program for interferences and errors before anything runs on the real machines. More than 25 different machining centres used at Premium AEROTEC are simulated using VERICUT. AUTO-DIFF is a very important VERICUT module at the Augsburg plant. It provides an automated identification of the differences between a CAD model and a workpiece simulated by VERICUT. Within the module, anyone involved in the manufacturing process can detect points that have been incorrectly processed, or errors in the programming. “It is an ideal tool, that is particularly important when extremely expensive parts are involved, and which, when it comes to allowances and tolerances has proved to be indispensable,” says Werner Flagner. “AUTO-DIFF helps cut programming time and speeds up the entire process,” adds Michael Hoffmann.

Given the high material removal rates, of up to 98 percent, is it even possible to achieve a reduction in production times – including setting up, parts handling, measuring, and run-through? There are several approaches to improving machining efficiency. These include machining in a single setting, with the integration of different manufacturing procedures. Ideally, the complete machining process takes place in ‘one-hit’ reducing positioning errors or damage to the components during manual handling. Optimised workholding strategies and new machine tools with modern cutting tools also have the potential to increase cutting speeds, material removal volumes, and improve machining qualities, while also increasing service life. However, process safety and security remains an absolute requirement in manufacturing, and that is why Premium AEROTEC has applied the new physicsbased module, Force, from CGTech to increase efficiency while maintaining operational reliability.

Force is the culmination of a joint development between CGTech and UTC (United Technologies Corporation). A physical and scientific optimisation method Force is a software module within VERICUT that uses known physical parameters to determine the maximum reliable feed rate for a given cutting condition based on four factors: force on the cutter, spindle power, maximum chip thickness, and maximum allowable feed rate. It calculates ideal feed rates by analysing tool geometry and parameters, material properties of the stock and cutting tool, detailed cutting tool edge geometry, and VERICUT cut-by-cut contact conditions. Managing Director, Tony Shrewsbury, explains, “It relates to helix and rake angle, as well as the general geometric form of the tool. What is decisive is the material type – carbide or hard metal or HSS – and the issue of when the tool breaks. As loading peaks are also displayed in Force, these can be managed and reduced to ‘smooth’ the loading to make the cutting action less ‘shocking’ to both the tool, workpiece and the elements of the machine tool.”

Another advantage is that Force does not need any user findings; it is optimised solely based on the values determined. Likewise, no elaborate software tests are required. He goes on to state, “The issue is not about milling strategies of existing programs. No tool path needs to be changed. Force simply divides, or splits, the path to introduce advances. Everything is governed by the feed advance, so the geometries are not altered.”

Premium AEROTEC has really gained right from the start with the new Force solution. The savings achieved so far are around 22 percent reduction in machine cycle times with programs optimised by Force, with a substantial improvement in tool life as well. Tony Shrewsbury is confident there are still more potential benefits to be seen in the future: “Force is extremely well-suited to materials that are difficult to machine, and for complex multi-axis operations. We are encountering both these factors increasingly, not only in the aerospace sector but in all precision machining industries. For real world efficiency gains, Force is the most innovative software currently available.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi