From 0 to 1200

April 6, 2022 7:09 pm

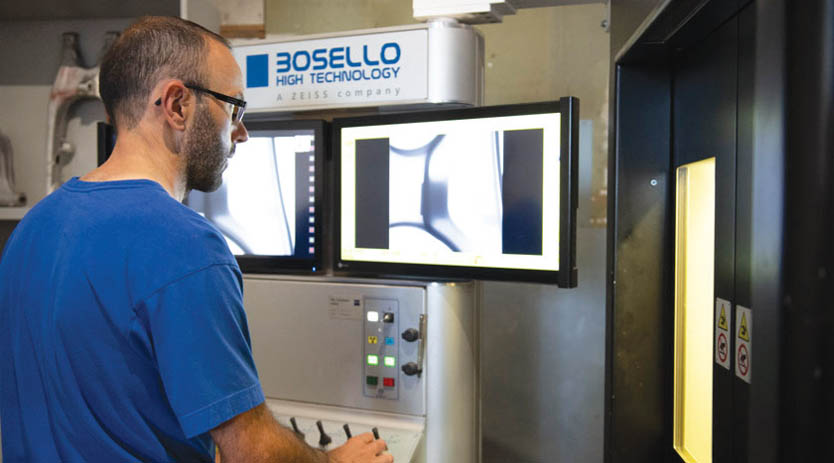

Additively manufactured pistons for the Porsche 911 GT2 RS to meet the highest quality standards developed by ZEISS.

Additive manufacturing offers enormous potential for optimised and new components alike. At Porsche, 3D printing technology is already being employed in several areas. And now, a joint project from Porsche, Mahle and Trumpf, in cooperation with ZEISS, has successfully 3D-printed highly stressed drive components for the first time, using generative processes to manufacture pistons for the high performance engine of Porsche’s top-of-the-line 911 model: the GT2 RS. The entire team headed by Porsche project lead Frank Ickinger is more than pleased: “This makes a performance boost of up to 30 horsepower conceivable with the 700PS twin turbo engine, and with higher levels of efficiency at that.” The “printed” high-performance piston project is a total success. A milestone in the history of additive manufacturing.

Baden-Württemberg connection: four partners, one objective

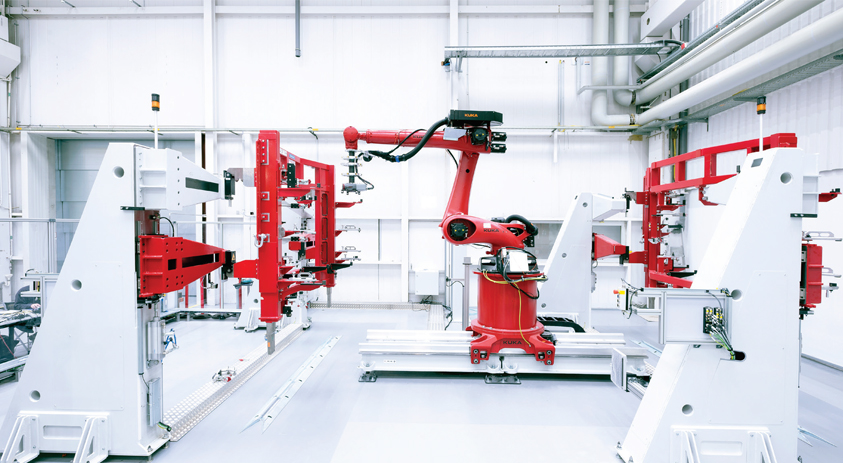

As in motor sports, the development and manufacture of the components is a team effort. The project is headed by Porsche. Mahle, a cooperation partner of the project, provides the requisite know-how for the development and manufacture of drive components and for additive manufacturing. Trumpf is the project‘s specialist for additive manufacturing systems, colloquially known as 3D printers. The quality and performance of the materials used and of the components is ensured by means of solutions from ZEISS. Quality assurance is essential across the many individual steps of the manufacturing process, from powder to finished component. To meet the specific requirements of this kind of manufacturing, a comprehensive quality assurance process was developed by ZEISS. The goal of the project, apart from manufacturing the piston prototypes and thus improving the efficiency of the components, is to develop an additive manufacturing process capable of meeting the highest quality standards while remaining lean and cost-efficient to make series production possible. This process will ultimately be used for the manufacture of other components as well.

The additive manufacturing process

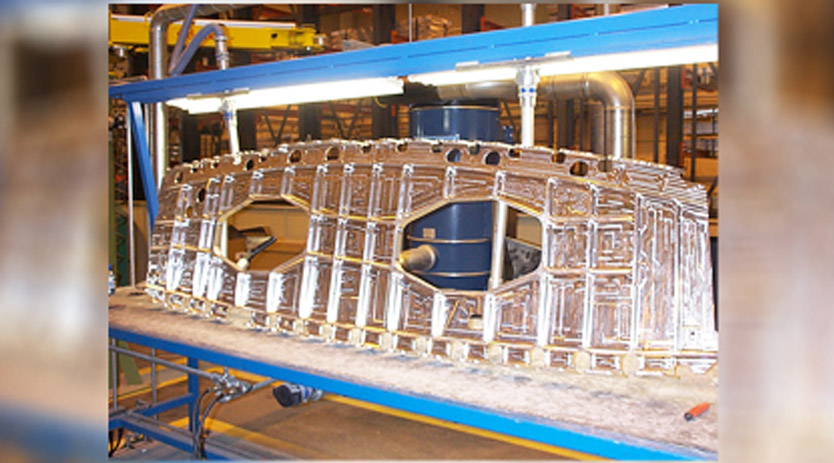

At the foundation of this manufacturing process is a metal powder made from a special alloy developed by Mahle. The powder is applied layer by layer inside a metal 3D printer from Trumpf and fused at selective points using a laser. Over the course of 12 hours, 1,200 layers are applied to form the piston blanks. To ensure that the 3D printed pistons meet the high requirements, a comprehensive quality assessment is needed. “With this piston material in particular, which had never been printed before, it was of course a challenge to generate the right component quality. “With the help of ZEISS, we were able to do this very well,“ summarises Frank Ickinger from Porsche‘s Advanced Engineering Powertrain division.

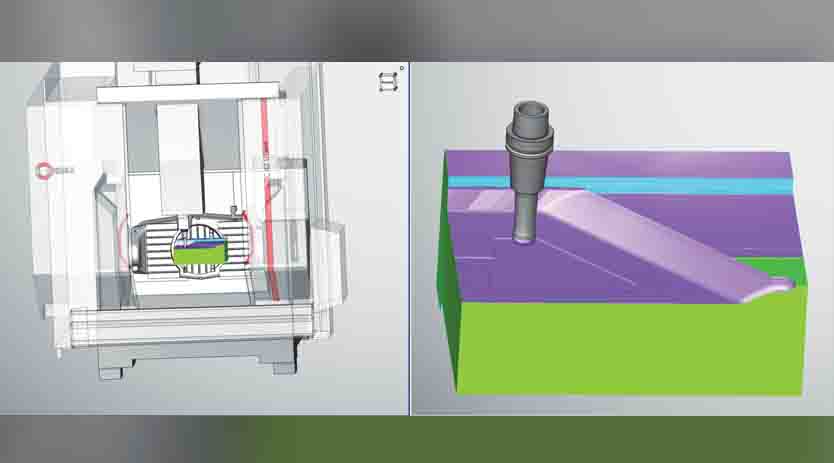

Optimising the design

A big advantage of this process is that it enables the creation of a novel bionic architecture. Topology optimisation is used to simulate the load paths and hence to define a structure appropriate for the load. As such, the advance development project is able to achieve a weight reduction in its pistons of 10 percent as compared to the welded series pistons. The 3D printed piston prototypes also feature an integrated cooling channel — this would not be possible with standard manufacturing methods. “With the new, lighter pistons, we are able to increase engine speed, reduce thermal load and optimise combustion,“ explains Frank Ickinger. From powder to performance components. The starting material used to 3D print the pistons is a powder developed by Mahle. But not all powders are the same. The powder‘s particle size distribution, particle shape, chemical composition and even porosity inside the powder particles are examples of properties which can influence component quality. The fact that the powder‘s properties can change each time it is reused must be taken into account, and deviations need to be detected in a manner that is appropriate for the production process.

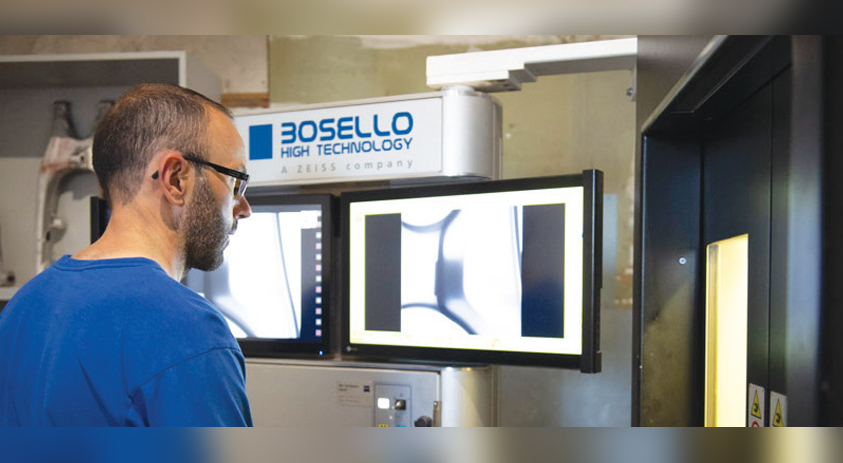

For example, if the powder‘s particle

Size distribution changes as a result of repeated use, the quality of the applied powder layer may be affected, and simultaneously the risk of pores forming as a result, or of other component defects arising, may increase dramatically. Light microscopes, scanning electron microscopes and X-ray computed tomography from ZEISS are used to analyse the quality of the powder before and after piston production, and the microstructure of the finished component is tested in order to identify defects or property characteristics. Through further processing of the analysis data and additional evaluation processes, it is possible to determine optimised settings for printing. Successful print results must also go through a variety of post-processing steps to ensure that the material and component properties are optimal. During process development, for example, the component‘s structure can be inspected using specially equipped scanning electron microscopes or X-ray computed tomography before and after the heat treatment processes. To analyse the impact of individual production steps on the final quality of the component, an optical 3D scanner or industrial computed tomography are used in addition to a coordinate measuring machine. The ability to seamlessly combine these procedures is a decisive factor. The pistons still on the print bed were scanned using a 3D scanner. Once they are removed from the bed, the individual production steps as well as the internal structures can be inspected using computed tomography while defect analysis is performed at the same time. At the end, a final measurement is performed with the coordinate measuring machine.The core capability of ZEISS‘ comprehensive quality assurance process is the linking of all data across the various analyses. On the test bench Now the 3D printed pistons must head to the test stand and prove themselves in the GT2 RS engine. In a 200-hour endurance run on the test stand, the components are subjected to 24 hours of high-speed driving, 135 hours of full load and 25 hours of towing load at various engine speeds, non-stop. “If 3D printed components can withstand loads such as these, it is possible to 3D print many other automobile parts as well,“ says Frank Ickinger enthusiastically. “Even though we simulated everything, to see the pistons work without any problems on the test stand — that makes me very proud,“ adds Volker Schall, Head of Product Design at MAHLE International GmbH. In the end, the results impressed many more people than just the engineers. All of the pistons passed the demanding tests without a single failure. A clear sign that the quality assurance process works properly.

Pioneers of additive manufacturing

Additive manufacturing offers enormous potential for optimised and new components. Combustion engines, for example, can be improved and made more environmentally-friendly. But there are also many opportunities to use these production methods in e-mobility as well. “We‘ve done pioneering work in additive manufacturing with this project,“ says Dr. Bernhard Wiedemann about the collaboration with Porsche, Mahle and Trumpf. “The resulting process in which the pistons are manufactured and at the same time the quality is analysed and ensured across the entire production process is one of a kind.“

Additional design freedom, lightweight construction and functional integration combined with quality assurance from ZEISS. The entire team behind Porsche project lead Frank Ickinger is more than pleased. The “printed“ high-performance piston project is a total success. A milestone in the history of additive manufacturing at Porsche.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi