Dalmec’s solution for handling multiple seat variants ensured effective space utilisation

July 5, 2021 7:30 pm

The case study highlights how Dalmec offered an indigenous solution to a leading automobile manufacturer to handle different seat variants and enabled the operator to work ergonomically in a compact work environment.

A leading luxury car manufacturer in India had an ambitious plan to expand its customer base and help the company to continue working on its vision of powering progress. To accomplish their goals, the company was planning to launch a new model in the Indian market. The launch of the new model required expansion in existing capacity.

The company was looking for-a proven material handling solution provider, to handle captain and complete type seats. While working closely with various clients for the last 60 years and more, we have gained knowledge necessary to design the right solutions – for every environment and applications. Our long-standing partnership with the client and a well-established track record, made us manufacturers’ obvious choice. Equipped with decades of experience in manufacturing manipulators for the auto and ancillary industry, we took this challenge and collaborated with the client to work on various aspects of the applications.

Project requirements and challenges

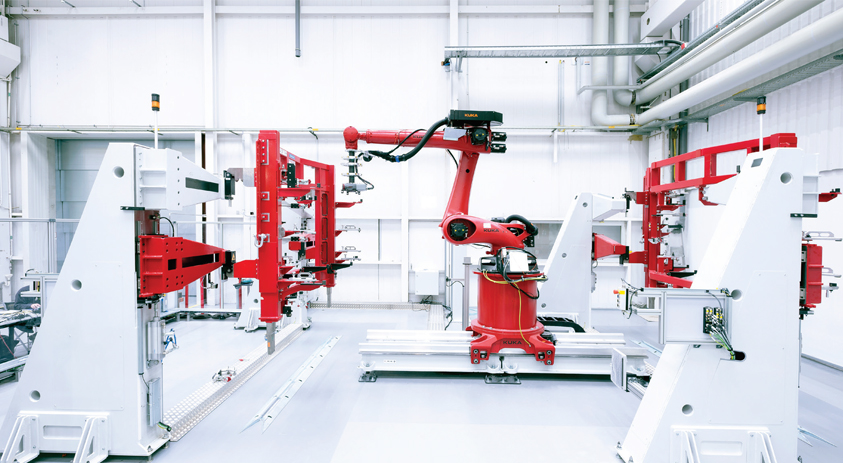

The augmentation of the existing facility resulted in limited space availability. In addition, during our site visit, we also observed that the existing cranes and plant utilities fully occupied the overhead rail arrangement. The captain and complete seats weighed approx. 35 and 60 kgs. respectively. While the captain seat mounting was a simple pick and place operation, the complete/ bench seat assembling required lifting and rotation movements.![page 47 [1]](https://www.oemupdate.com/wp-content/uploads/2021/07/page-47-1.jpg)

Dalmec’s solution:

After taking all the inputs from our client, the Dalmec team went to the drawing-room to custom build the manipulator suitable to work in compact space and, if possible, design a single solution to handle all the variants.

The team conducted an in-depth study of plant layout, min. & max. load and lift condition ‘and manipulator, in reaching requirement to offer a solution that could efficiently handle all types of seats and carry out installation at LH & RH side. We followed of European standards of safety and quality guidelines, thereby ensuring worker safety and product reliability. The seat assembling is continuous and repetitive operation; hence we conducted a comprehensive ergonomic study to facilitate fatigue-free operating conditions.

Considering floor space constraints, we initially thought of an overhead track system. However, the site conditions did not allow us to have an overhead manipulator. So, we started working on the concept of a column mount manipulator with inter-changeable grippers. Dalmec requested the client to arrange seat samples for designing the manipulator gripper. After a detailed study on seat material, cushion contour and possible gripping points, we suggested a scooped gripper to handle the captain seat and a jaw type gripper to lift and rotate the complete seat. Rubber padding was provided on grippers to protect cushions while gripping action.

Considering the long length of the complete seat and LH & RH installation conditions, Dalmec proposed an extended arm manipulator. The extended arm countered the offset weight of around 40 kg and allowed component handling at practically no-load condition. A leather covering was provided over the extended arm to prevent damage to the automobile body during installation process.

Benefits for the client:

- Single solution for both variants ensured effective utilisation of space.

- With our manipulator the operator gained control of seat movement in assembly line; thereby eliminating chances of accidents.

- Specialised grippers facilitated quick gripping without damaging seat cushions.

- Our solution notably reduced the physical fatigue of operator and increase productivity.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi