Redefining pressure management for pharma sector with VEGA

March 20, 2021 11:59 am

This article talks about the uses and impacts of VEGA’s measuring instrumentation, adaptors, and adaptors across the manufacturing processes in pharmaceutical sector.

Pharmaceutical manufacturing involves critical yet diverse processes that decide the fate of the end product, which needs to be within the prescribed regulation as laid by law enforcement authorities. These processes include mixing, evaporating, filing and CIP/SIP cleaning. The success of these processes also depends upon the instrumentation that is being used by the manufacturer. Each of the instruments involved in the process is required to be adhering to certain standards of hygiene and required process parameters, and at the same time be able to deliver precision and reliability to the process. The instrumentation should also empower the operator to find right balance between longevity and maximum productivity. Understanding the pain points, instrumentation veteran- VEGA offers a measurement instrumentation portfolio consisting level sensors, pressure sensors and level switches, each giving distinct advantage to the manufacturer.

Uncompromised precision

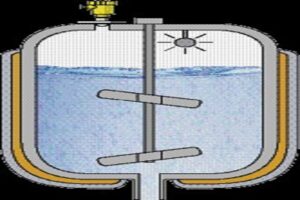

Pharmaceutical manufacturing, typically will have bioreactors and fermenter vessels, which commonly employs bottom agitators, side jackets for propagation of cell growth in seed or production reactors. Such internal installations may cause problems while taking level measurement, giving false echo thereby unreliable measurement. However, thanks to its strong beam angle of our devices based on 80 GHz radar technology, for example, VEGAPULS 64, the uncompromised precision in taking measurement is absolutely possible. The 80 GHz based radar sensors are able to deliver precise measurement in all process conditions, be it an aggressive media, high temperatures and pressure, foam generation or condensation. The uncompromised precision in delivering measurement helps optimizing the production processes and adherence to the product quality as per the set-regulations.

Pharmaceutical manufacturing, typically will have bioreactors and fermenter vessels, which commonly employs bottom agitators, side jackets for propagation of cell growth in seed or production reactors. Such internal installations may cause problems while taking level measurement, giving false echo thereby unreliable measurement. However, thanks to its strong beam angle of our devices based on 80 GHz radar technology, for example, VEGAPULS 64, the uncompromised precision in taking measurement is absolutely possible. The 80 GHz based radar sensors are able to deliver precise measurement in all process conditions, be it an aggressive media, high temperatures and pressure, foam generation or condensation. The uncompromised precision in delivering measurement helps optimizing the production processes and adherence to the product quality as per the set-regulations.

Bringing colour in view, intelligently

The product families VEGABAR and VEGAPOINT prove that automation can be quite simple and highly efficient at the same time, without compromising on dependability, hygiene or accuracy. The new measuring instruments are perfectly tailored to standard applications that nevertheless do not tolerate compromises when it comes to quality. The pressure sensors and level switches are equipped with 3600 switching status, hence making it easy for an operator to monitor the process event from the distance. The choice of 256-colour combination gives an operator freedom to set parameters as per personal choice and process environment. Additionally, there’s a lot of sensor intelligence built right into the new compact series: the standard IO-Link protocol ensures universal and, at the same time, particularly simple communication. This means that the instruments have a standardised communication platform that enables seamless data transfer and simple integration of the system. With this tool, sensors can be installed, parameterised and, if necessary, put back into operation faster and more cost-effectively. IO-Link transfers parameters automatically if an instrument has to be exchanged.

Hygienic adapters

Be it a level sensor, pressure sensor or level switch, VEGA has a standardised hygienic adapter that perfectly fits the requirement of the manufacturer. This also helps them to employ these sensors without any on-site modifications making the installation easy and cost-effective. In addition, it helps in reducing the down-time when sensors need to be changed as well as optimizes the manufacturer’s inventory as fewer instrument versions can be stocked as the fittings can be interchanged.

Be it a level sensor, pressure sensor or level switch, VEGA has a standardised hygienic adapter that perfectly fits the requirement of the manufacturer. This also helps them to employ these sensors without any on-site modifications making the installation easy and cost-effective. In addition, it helps in reducing the down-time when sensors need to be changed as well as optimizes the manufacturer’s inventory as fewer instrument versions can be stocked as the fittings can be interchanged.

Zero-incompatibilities

The instrumentation used in pharma manufacturing should adhere to certain surface roughness criteria, instrument housing and specific requirements of the wetted part that comes in contact with the medium. Unless these are strictly observed, chances of contamination are abundant. VEGA delivers instruments that complies with standards like 3-A, complete SS housing and securely protected sealing eliminating the contamination fear.

Easy set-up and accessibility

The new VEGABAR and VEGAPOINT instrument series can be easily read out and configured via Bluetooth with a smartphone or tablet. Radio technology is making processes more flexible. Wireless communication provides better accessibility. It allows parameterisation, display and diagnostics from a distance of up to 25 meters, thus saving time and avoiding dangers. Especially in environments such as clean rooms, where physical access involves a lot of effort, setup and operation become considerably easier.

For more info, visit: https: https://www.vega.com/en-in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi