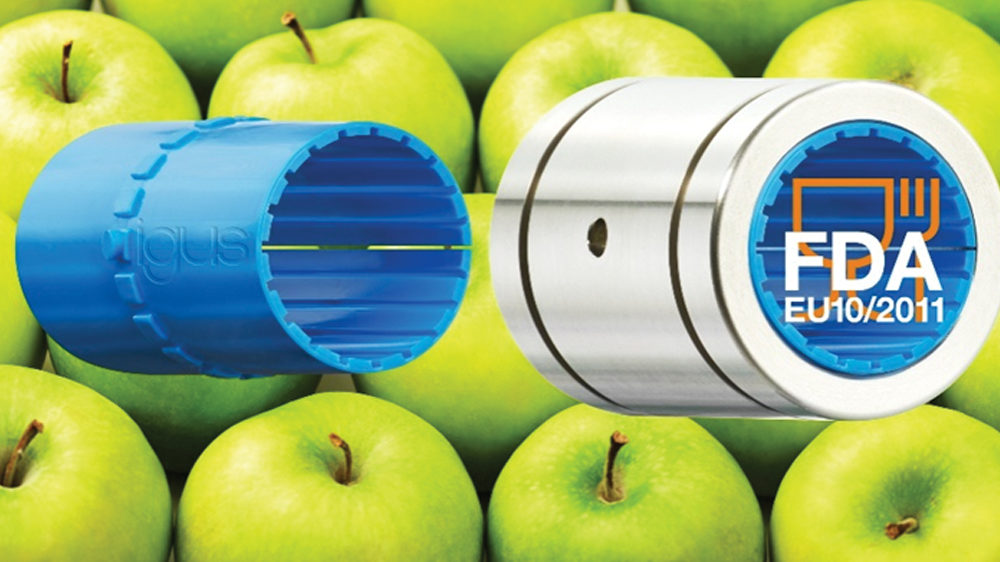

igus launches FDA-, EU-compliant plastic liners

October 8, 2018 3:02 pm

New igus linear guide systems has been tipped to ensure precise and quick adjustment of machines in the food and beverage industry, according to the company. Integrated, maintenance-free and wear-resistant liners used in the carriages enable the linear guides to glide without lubrication. The firm has now developed an FDA and EU-compliant liner made from the high-performance plastic iglidur A160, which is particularly suitable for the special hygienic requirements of the food industry. It is particularly characterised by its long service life

on FDA and EU-compliant stainless steel shafts and in wet areas.

The food industry requires its installed machine elements to be clean, lubrication-free and corrosion-resistant, making maintenance-free plastic solutions the right choice.

Lubrication-free linear guide systems from igus are already being used in numerous applications in the food and packaging industry, be it in beverage filling systems or in the bottle processing industry. Liners made of high-performance plastics ensure a smooth and clean adjustment. Users can now rely on hygienic linear guides, thanks to the new lubrication-free linear plain bearings made of iglidur A160.

The blue material complies with the FDA and EU Regulation 10/2011 EC and is, therefore, suited for the special requirements of the food industry. The iglidur A160 has a high and online-calculable service life on stainless steel shafts, even in wet areas. The high-performance plastic is also characterised by its high media resistance. Another advantage is that the liner is impervious to contamination thanks to the integrated dirt channels, and is easy to clean and

replace. The new linear bearing component is currently available in eight dimensions for all drylin W housing bearings and carriages as well as for all drylin R round guides.

In the company’s own 2,750 square-metre test laboratory, igus has tested the new liner on various stainless steel shafts vis-a-vis plastic liners that are already in the igus range made of iglidur J200, iglidur J, iglidur A180, iglidur E7 and iglidur X. The iglidur J200 is an established standard material on aluminium shafts, while iglidur J is suitable for all shaft surfaces. For users who rely on drylin linear systems with steel shafts, igus has, with the iglidur E7, an endurance runner in its product range, while the use of iglidur X liners is particularly suitable for applications requiring high temperature resistance and high chemical resistance. The wear test clearly showed that the new iglidur A160 liner has the best wear values on various stainless steel shafts. Therefore, the new liner is an ideal sliding partner for stainless steel linear guides used in the food industry.

For more details, visit, www.igus.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.