Dimensionally interchangeable gear boxes

December 16, 2019 12:34 pm

“Vijay Gears” is one of the leading manufacturers of industrial gearbox and industrial gears. Vijay Gears is an ISO 9001:2015 certified company. The company is a proud member of AGMA. Vijay gears is also into gear manufacturing business for more than 20 years and started the manufacturing of various types of gear boxes with brand name of Vijay Gears since 2015. Our operation base is running in MIDC, Waluj, Aurangabad, and Maharashtra.

Product profile walk through

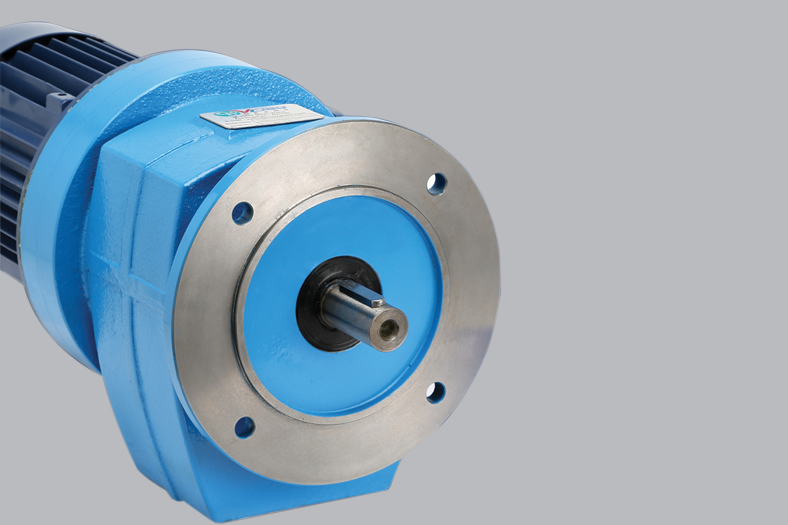

Now the Vijay group of industries is having three large units, engaged in manufacturing. The major share of our business is from Inline Helical Gear Boxes. These Gear Boxes are dimensionally interchangeable with the Gear Boxes of other major manufacturers. These Gear Boxes are suitable to be coupled with three phase induction motors of any make.

Our ranges of Inline Helical Gear Boxes are suitable for electric motors with capacity of 0.37kW to 7.5kW with IEC frame sizes 71, 80, 90, 100, 112 and 132. We can offer various gear ratios. Also, for all our gear boxes we offer one year complete replacement warranty.

The vertically served industries with these gear boxes are automobile, bulk material handling, web- offset printing, pharmaceutical, sewage treatment, textiles, cranes, hoist, agitators / mixers, conveyors, compressor, solar trackers, automised gates, agriculture equipment, oil industries food processing etc.

We also manufacture automobile components, gears and miniature Planetary Gear Boxes up to a Torque capacity of 50Nm. We are expert to supply custom build PMDC motors along with these planetary gear box.

Forging blanks and round bars sourced from reputed forging companies in India. The material under goes series of quality check to ensure high reliability of the gearbox. The gearbox housing is provided in cast iron. Sturdy and robust housings give the gear box high tolerance to absorb high shock load. Other bought out material such as bearings and oil seals are directly procured from reputed manufacturers.

Our manufacturing units are equipped with modern state of the art CNC and VMC machines and other infrastructural equipment’s to produce precision gears so as to meet the best quality standards. In- house manufacturing includes Shaft and Blank Turning as well as CNC Gear Hobbing, Gear Shaping, Gear Shaving, Cylindrical Grinding, Gear Teeth Profile Grinding all under one Roof. We also have Lead profile Tester.

Now we are enhancing our production capacities along with the addition of new machines of cutting-edge technology. Also, we are in the process of setting up an in-house heat treatment facility.

Our team includes experienced technocrats and engineers who are continuously developing gearbox to best suit the end user application. Vijay Gears Products are distributed throughout the India through more than 50+ dealers appointed in various regions in India. Now our main mission is to focus on International Market and spread the business in International market by year 2020.

We would be pleased to receive the enquiries giving us the technical specification such as power capacity, output speed, mounting options (i.e. foot or flange) and application etc. to advice a most suitable offer. Our strength is quality, timely delivery and prompt service to the customer.

Environmental safety steps taken by Vijay gears

- We do not use Thermocole or plastic for packing.

- Water Harvesting is done in factory building

- We have planted about 1300 plants and also taking care of all the plants. Separate agency for watering these plant are hired.

- Managing Director Digambar Muley is now Vice Precedent of Marathwada Environment Cluster – Chapter Waluj.

Ensuring ease of operation, durability, reliability, energy efficiency and productivity for a gearbox

Design optimisation for streamlining raw material consumption per gear box without affecting strength. All department functions are controlled and eased through ERP System. Close controls on Production processes. We are in process of implementing 4.0 Industries software. Usages of efficient Machines, right Toolings and users friendly Jig fixtures for better productivity. Trained work force.

Authored by :

Digambar R. Deshpande,

0CEO, Vijay Gears

Email: ceo@vijaygears.com

website: http://www.vijaygears.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi