Automation and digitisation in drives to match market potentials

May 1, 2021 5:20 pm

Global Industrial Automation market size is valued at $168.81 Bn as per 2019 results and projected CAGR are about 9 percent for the next 5 years.

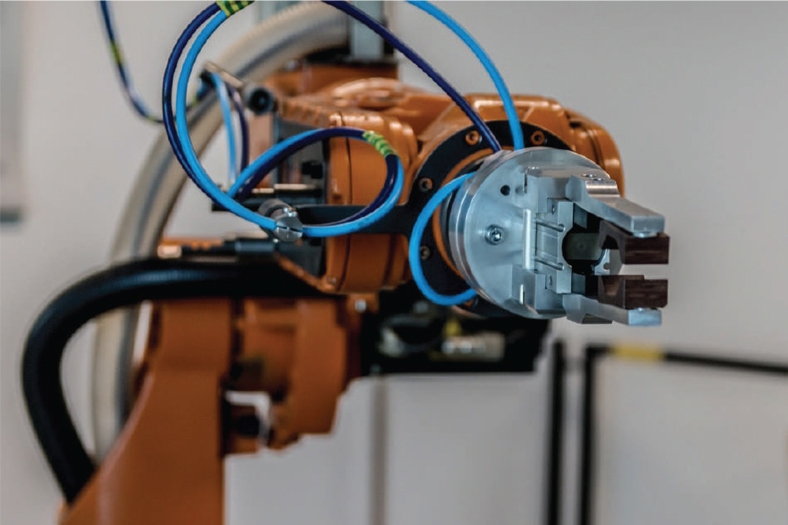

Increasing adoption of Industry 4.0 and the advent of 5G wireless technology is propelling the demand for Automation across several Industries. Impacts of global automation market trends Talking about the aspects impacting the demand for automated drives, PL Muthusekkar, Managing Director, Nord Drive Systems, says “By expediting processes and minimising human errors, the advent of automation and connected devices allow industries to innovate and grow fairly, and rapidly.” Automation consists of a control system that performs tasks for its users, thereby, reducing the need for manual intervention. Automation market size is also experiencing disruptive trends. Today, India tries to raise its bar in each and every aspect, a new project deliverables can be seen where we are benchmarked with international standards. Aspects of energy-efficiency and savings are central to every new upcoming project.

Here, on this note, Vaibhav Pitale, Managing Director – India and, South West Asia, Belimo says, “Even the old installations are being upgraded on these fronts as it brings along a considerable savings in operating costs.” At Belimo, we follow the CESIM philosophy which makes sure our products add value in terms of –

C – Comfort and wellbeing of occupants

E – Efficiency

S – Safety which is uncompromised when it comes to human life and assets

I – ease in Installation

M – Peace of mind during the maintenance phase

So, we make sure our products have a great impact on efficiency. We call it small devices-big impact.

Dealing with the challenges amid pandemic restrictions

All industries have been impacted by the COVID-19 crisis, with varying degrees of severity. Some of them have stronger defences, while others will struggle to return to a constantly shifting “normal.” “Consumer demand patterns are shifting, global supply chains are disrupted and remains to be under pressure and different regions, markets and governments are responding uniquely to the COVID-19 crisis,” says Muthusekkar.

Even the companies should incessantly adapt to new and uncertain market conditions and be prepared for such uncertainties. Travel restrictions and restricted customer visits are biggest challenges we face being an Engineering Industry; but thanks to the digital era that our sales team could have daily conversation with our customers via VCs etc. Employee safety and precautions is another difficult yet vital task to embark upon. Luckily, we do not have any manpower issues in general and the same situation in our sector too.

Discussing the same, Pitale says, “We were very fortunate enough that we could open up our customising centre by end of April 2020, we were positioned and were ready to serve our customers during such trying times.” This step was highly regarded and appreciated by our entire clientele that we were in a position to not only supply our products for many of the initiatives taken by the government but for also being able to present and provide the service support whenever and wherever required. All this would not have been possible without the support and commitment of our workforce.

“In a way, I feel our presence brought an ease to many during the toughest period”, adds Pitale. Opportunities under Skill India for skilled manpower The Skill India scheme is a smart initiative that works towards the development of Country as a whole. This initiative was launched by Government to train over 40 crore Indians to create an empowered workforce. “We at Nord have implemented few programs successfully. One of the initiative to highlight is Gear Guru Campaign designed to improve the product awareness, basic technical knowledge and know-how for our customers and Chanel partners which would definitely help them in better product selection and customisation. We are also taking efforts for skill enhancement of our employees by arranging technical and soft skill trainings”, says Muthusekkar. One more initiative is to connect with engineering colleges and interact with students to sculpt the raw talent and make them Industry ready. We have entered MOUs with 13 engineering colleges, RCC Institute of Information Technology, Kolkata being latest added.

In the interest of Industry collaborating with institutions, we started this initiative in year 2012. Pitale is on the same line with Muthusekkar. According to him, skill India Initiative is a highly significant step needed to make sure we our nation has the right manpower to produce quality Make in India products. “This initiative will make sure we have a pool of skilled people to bank on and will serve as the backbone for the success of Make in India. Digitalisation and Automation gives you great opportunity to map the skill sets based on AI and machine learning to unleash the potential and map right skills for a particular role”, adds Pitale.

Catering to demands of automated control systems Muthusekkar here highlights their products and services and says that NORD DRIVESYSTEMS produces geared motors which can be adapted and customised for almost every application. We work closely with our customers to find the optimum solution for their requirements. Millions of NORD geared motors are already in use throughout the world and provide ultimate performance in various industries every day. “Our geared motors provide superior performance in addition to high axial and radial load capacity.

Thanks to NORD’s modular design concept, customers also benefit from industry leading delivery times”, he adds. Nord Drive Systems offers customised combination of Mechanical (Gear Unit), Electrical (Motor) and Electrical (Inverters, motors starters and field distribution systems) products serving innovative drive solutions for more than hundred branches of industry. All NORD DRIVESYSTEMS geared motors are Industry 4.0 READY ex-works offering advantages like predictive maintenance, reduced downtimes, Reduction of service and material costs etc. Talking about the automated control systems, Pitale says that Belimo has carved a niche in providing innovative solutions, quality products and most importantly quick delivery. Briefing on Belimo’s products, he adds, “Our sensors, controls valves and actuators are used for automation and control of HVAC systems example NFC, some of our products can actually get connected to the cloud and data can be stored for future diagnosis.” The sectors showing promising growth potential are metros, airports, pharmaceuticals, healthcare and data centres which will go a long way consistently to boost the economy of our country.

The way forward

The term Industry 4.0 or Industrial Internet of Things (IIoT) includes the intelligent interlinking of digital data and processes with the physical world, i.e. with humans, machines, and smart objects. The industry expects expansion in Logistics, Warehouse Automation, textile industry, machine tools and material handling sectors.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi