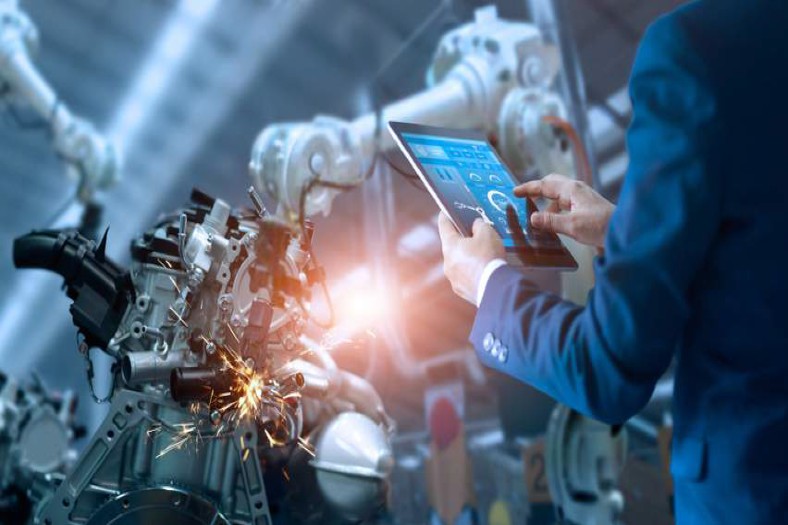

AI and IoT to speed up transformation of Indian manufacturing industry

June 9, 2022 6:26 pm

3D printing, drone tech, and AR are some technologies that will soon make a tangible impact in the automated Industry 4.0 era.

Talking about response to current trends such as IoT, Industry 4.0, and AI, Ajay Gurjar, COO & Director, YASKAWA India told OEM Update that Yaskawa is promoting i³-Mechatronics as a solution concept.

Trends and innovations that are impacting the robotics and automation industry?

Robotics & Automation will continue to transform manufacturing in numerous ways. But, there are few major trends and Innovations in robotic automation that are playing a key role with adoption of industry 4.0/5.0. Robots and automation will increasingly deploy smart sensors at the edge of production to collect data, previously inaccessible to manufacturers. Also, Industrial Cybersecurity, as robots become more connected to internal systems for data collection, the cybersecurity risks increase. Manufacturers will be forced to address vulnerabilities in their processes and invest heavily in cybersecurity to ensure safe, reliable production. Robots with industry 4.0 /5.0 now became a key source of information on the factory floor. The collection of data (BIG data Analysis), however, is just one piece of the puzzle. Manufacturers will have to implement systems to organize and analyze all this information in order to act on it. Virtual solutions have become an integral part of industrial robotics. One current growing application is the virtual representation of robotic systems for proof of concept, offline programming and AR/VR System. Also, the receding global pandemic has certainly crippled many industries. Also there exists the need to reduce manufacturing downtime and speedup product development lifestyle while keeping observation & Control through industry 4.0/5.0 Solution.

With all the disruptions due to Covid-19, now, New India also is all about change, I feel manufacturing giants including MSMEs should be proactive and not reactive with Industry 4.0 to tap their plants running to full capacity without any disruptions. First step that must be taken by companies is to be open for change, safe network, digitization & Implementing Robotic automation system. Yaskawa can provide the solution with all our products like Robot, servo & Drives with most adoptable Yaskawa cockpit best OPUA based industry 4.0 solution from which customer can make strong base for Smart factory.

What are your products and solutions?

Yaskawa India has emerged as a central hub for the future goals which is headed by a dynamic sale, service, training, and technical support team. To satisfy the current requirements Yaskawa Product like Robot, Servo & Motion controller helping customers to obtain their solution. Our current Robot Product range gives customer flexibility to choose product payload 0.3kg to 800 kg payload with the reach of 0.5 m to 4m for Arc, Spot, Handling, Press, Painting & working with Collaborative requirement YRC1000 Controller. Our products and solutions have been supporting automation in a wide variety of industrial fields including automotive, machine tools, FMCG, Electronics, Packaging, textile, crane, ceramics, and life sciences. We as a pioneer in these sectors, always strive to optimize the productivity and efficiency of machines and industrial systems with our innovations.

In response to current trends such as IoT, Industry 4.0, and artificial intelligence (AI), Yaskawa is promoting i³-Mechatronics as a solution concept. Yaskawa’s industrial robots are the core products to actualize this concept. Our state of the art medium voltage AC drives, system-use AC drives, and system controllers have many use cases, including iron and steel systems, water waste management, etc. 30 million inverters, 20 million servo axes and 500,000 robots in the field are proof positive that Yaskawa has the engineering expertise, innovative technology, and unsurpassed quality to inspire complete customer confidence.

Manufacturing with Industry 4.0/ 5.0 to optimize production

The way India has embraced digital adoption has played a critical role in shaping the roadmap for Industry 4.0. From analytics for incisive insights to creating sophisticated virtual designs, the Indian manufacturing industry in the 4.0 era can benefit from digital adoption at all stages. Digital technology is the basis on which we can even talk about the 4th great industrial revolution. It supercharges all aspects of manufacturing with radical improvements in speed, quality, productivity, and flexibility. Take the combination of big data and IIoT as an example. The combo unlocks a whole new level of understanding of how the various product assembly line processes can be improved using quality data insights in real-time.

Yaskawa is amongst the top 100 innovative companies who has established its footprint in AI with the help of automation techniques developed by the company over more than half a century like Servo Motor, Drives, Robot, Yaskawa Cockpit & Smart factory solution which help industry to maximize their productivity. It implies to AI in robotics with exposure of current industrial development of industry 4.0 where Yaskawa has developed “i3- mechatronics” solution concept bringing together classical mechatronics, information and communication technology with digital solutions such as AI, Big-data and IoT which demonstrated in Yaskawa Solution factory, Iruma.

The “Yaskawa Solution Factory” (Smart Factory) that was prepared at the Iruma Plant (Iruma City, Saitama Prefecture) was completed in July 2018 and began fullfledged operations in December. The concept of the plant is a” next-generation production plant that will change manufacturing and business.” Dramatic productivity enhancement was achieved at the plant.

PLI leverage AI and IIoT in manufacturing to ramp up production

The end-to-end visibility that AI provides, is a game-changer for the global manufacturing industry. By employing artificial intelligence manufacturers can track core KPIs like OEE, production rate, or scrap rates. Troubleshoot production bottlenecks and Ven forecast accurate delivery dates, leading to increase trust .

The PLI scheme comes at the right time when global geopolitical sentiment is somewhat hostile, but on the contrary, there is a growing dependency on cross-country imports. And, so here lies an opportunity to satiate the global demand and take in substantial profits in return. AI and IoT are two technologies that can help speed up the transformation of the Indian manufacturing industry. While IIoT helps collect data from equipment or ‘Things’, AI can help us analyze and find the best steps to make the necessary changes. We are talking about tons of data generated in real-time on the production floor from machines. It makes detecting anomalies, analyzing patterns, and predicting user behavior a more calculable decision.

When married to advanced machine learning algorithms, we have a selflearning, adaptive intelligence working out millions of computations working toward improving production. Not only does it ramp up the overall production but reduces manufacturing cost per unit and improves quality by some distance.

Smart factories evolving with AR and autonomous robotics implementation

When Smart-factories come into play – a hybrid workplace where you will see everything automated, with robust robots working in collaboration with humans. The new-gen robotics and automation ride on the back of advanced AI and machine learning, along with advancements in more flexible and IoT-responsive Servos that allow fluid motor movements. It seems soon the word ‘smart-factories’ will go redundant as almost all manufacturing units will be at least semi-automated. Robotic arms, Cobots, or AI-driven Robotic Process Automation (RPAs) in supply chain assembly lines will become a usual sight. Not to forget, 3D printing, drone tech, and AR are some technologies that look promising and will soon make a tangible impact in the automated Industry 4.0 era.

Apart from investment, a substantial downtime happens during training recruits or upskilling existing technicians. But with AR and VR in the mix, this would not be an issue anymore. Now the “model-based digital twin” offers immense flexibility and risk-free training using virtual avatars of machines. The VR headsets make learning an immersive experience that is easy to recall when confronted with real-job scenarios. Whereas AR-enabled devices allow accessing superimposed details as you hover over the machinery, ensuring accurate restoration or maintenance while mitigating errors exceptionally. To summarize, AR can help smart factories reduce training costs, minimize human errors, and help employees grasp concepts better. As fast as autonomous bots are concerned, they can further reduce human error and improve the speed and accuracy of routine manufacturing operations. Especially on warehousing and manufacturing floors, Cobots work alongside humans reducing accidents and replacing humans in more hostile work environments.

Market for drives and motion controls

There is no doubt that drives and motion controls technology will be at the center, for R&D engineers owing to its inevitability in robotics. As SMEs globally go all-in on automation, Robots are replacing people for many mundane and repetitive tasks in manufacturing. We like to call them – Robotic Process Automation or RPA’s. Robots are helping humans push the boundaries of research and testing by facilitating engagement with hostile environments without risking lives. And since machines are taking up the heavy chunk of lifting, scientists can now focus on high-value innovations and research. So, it is only a matter of time before we will see a sharp rise in demand for the motion and control market, which is directly proportional to the mass adoption of Cobots in the smart factories.

Growth expansion plans the company has with respect to automation

Yaskawa India has planned for its future endeavors on YASKAWA’s 100th anniversary in 2015. Our Vision 2025 is to contribute to solve customer needs and issues. Also, adding evolution of core business and expansion into the new fields by applying mechatronics technology. Yaskawa India’s future road map’s main aim to set Factory Automation/Optimization and Applications of Mechatronics Technology. We are trying to focus our efforts in particular areas. Few of them are: Humatronics, Food & Agri, Energy Saving, Clean Power, Skill Development. Yaskawa has identified the challenges that are faced by the robotics industries and with deep thoughtfulness and our vision 2025, we would solve all the customer requirements and develop more ideas

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.