E-coating increases efficiency of coating process

December 16, 2019 12:34 pm

Powder coating, E-coating and the criteria to determine what works best for the manufacturing operations

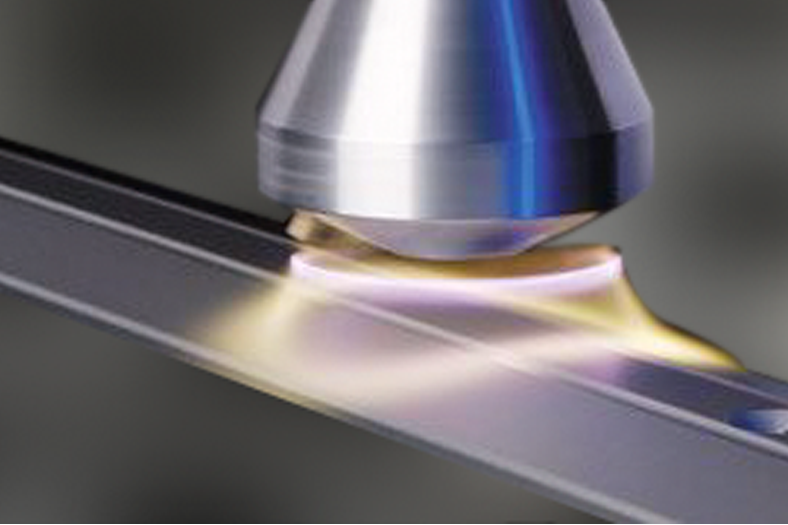

Powder coating is a dry finishing process that uses finely ground particles of pigment and resin that are electro statically charged and sprayed onto electrically grounded parts. The charged powder particles adhere to the part and are held there until melted and fused into a uniform coating in a curing oven.

Since its introduction more than 40 years ago, powder coating has grown in popularity and is now used by many manufacturers of common household and industrial products. In North America, it is estimated that more than 5,000 finishers apply powder to produce high-quality, durable finishes on a wide variety of products. Powder coated finishes resist scratches, corrosion, abrasion, chemicals and detergents, and the process can cut costs, improve efficiency and facilitate compliance with environmental regulations

Because powder coating materials contain no solvents, the process emits negligible, if any, volatile organic compounds (VOCs) into the atmosphere. It requires no venting, filtering or solvent recovery systems such as those needed for liquid finishing operations. Exhaust air from the powder booth can be safely returned to the coating room, and less oven air is exhausted to the outside, making powder coating a safe, clean finishing alternative and saving considerable energy and cost.

E-coating is an immersion wet paint finishing process that uses electrical current to attract the paint product to a metal surface. This process is also referred to as paint deposition. The E-coat process is a dipping (immersion) system very similar to what is used in metal plating except the finish uses organic paint particles not metal particles in the immersion baths.

Electro coating applications use paint particles suspended in a fluid bath. An opposite charged part is lowered into the paint bath and the paint particles are drawn to the metal part. The paint particles build up on all surfaces of the metal part to form an even, continuous, low-profile film over the entire surface. This process continues until the desired film thickness is reached. Film thickness is regulated by the amount of voltage differential applied. The higher the voltage, the thicker the film builds.

Working on the principle that opposites attract, an e-coat system applies an electrical charge to either the metal part, or the fluid in the immersion tank. The paint is than attracted by one or the other being grounded. The process can be performed either way, however there are benefits of having the part grounded (-) and a charge applied to the solution (+) vs. having the parts (+) positively charged and the tank solution holding a (-) negative charge. Depending on the polarity of the charge, either a anodic or a cathode method can be used for e-coating.

“E-coating a process best described as a cross between plating and painting, requires a metal piece to be immersed in a water based solution and powder coating which is a type of coating that is applied as a free flowing, dry powder are coating methods whereas masking is the process of isolating a specific area from the coating/painting. Irrespective of the method being used, masking, wherever required, is a vital part of the process. However, it is well known that e-coating is more apt in terms of the coverage that it offers and the fine coat that it gives due to nature of its application.” Explains Ajit, Ajit industries Pvt Ltd (AIPL).

What are the benefits of having automotive paint masking tapes?

Automotive paint masking tapes, as the name suggests are specifically used and hence designed for automotive manufacturers during paint jobs in a manufacturing unit. Now, the key benefit of having an automotive tape is to protect the surface from undesirable painting, wax, sealants etc at the assembly line.

This eradicates the need for a lot of post assembly line tasks like priming and cleaning and brings out the beauty of the paint job through precise application.

There are die-cut masking tapes that provide the benefit of application with pin point accuracy to give our precise results and an extremely professional finish.

There are also various grades of masking tape with varying temperature resistance to suit the need of different manufacturers that are suitable for oven baking & for body under seal protection.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.