Automation to complement key areas of hydraulics

December 16, 2019 12:09 pm

In spite of concerted efforts to improve its image in recent decades, hydraulics is still seen as a dinosaur by many users. As a result, it is not the first choice among young recruits. Graduates tend to be drawn to start-up environments with their digital business ideas and, in the figurative sense, to the object of desire—a golden unicorn.

Internationally, the unicorn symbolises innovation and creativity—ideas with a wow factor that make a lot of money. Regardless of how the outside world perceives hydraulics, the global economic importance of hydraulics is undisputed, with sales amounting to many tens of billions of dollars. Paradoxically, the economic importance of fluid power technology still contrasts sharply with the way it is perceived by users, the public, and the scientific community.

Smart industry solutions provided in hydraulics and pneumatics

Hydraulics and / or Pneumatics today are serving Industry as a backbone in contemplating, designing and applying to most intricate and complex motion and power control problems, which many times are found difficult to be handled by pure mechanical or electrical systems alone.

HYDRAULIC / PNEUMATIC Systems are broadly divided into INDUSTRIAL , MOBILE , DEFENCE , MARINE and AVIATION segments and the product selection for each is based on its environmental safety norms, noise and vibration control, Contamination control, risks and hazards and the technical capability of individual products that will answer the above to go into making systems for each of above segments.Thus the smart solutions for Industrial applications alone ,provided today in Hydraulic /Pneumatic systems are broadly based on following.

- The optimisation of control to provide for the correct application need.

- Product selection for ease of Maintenance, longer life span of equipment andbigger intervals in maintenance schedules.

- Light weight ,compact, highly integrated but sturdy designs for systemised power units and Control stands.

- Ergonomical design of system – based on manufacturable and acceptable quality norms, with/without data acquisition system embedded for diagnostic approach.

- System design even in its conceptual stage, based on low contamination generation techniques.

- Industrial Internet of Things, and integration with digital technology to give proper diagnosable and controllable system, with online and offline maintenance support,with periodic and predictive maintenance as a main driving element to give zero down time in productivity.

Monitoring the state of a hydraulic fluid

Hydraulic systems in today’ industry use many types of system fluids including Mineral oils, Phosphate esters, Water glycols, and even plain tap water. Hydraulic systems can be made extremely reliable and highly productive,if the fluid used to operate it, is kept in the best of its health and continuously monitored to stay that way throughout the life of equipment.

“Product’s capabilities today are enhanced by making them operate at elevated pressures like 350 bar instead of 210 bar as was 15 years ago. This pressure capability rise will further increase to say 400 bar in near future, by having appropriate materials available now in Industry to make hydraulic products. This high pressure capability calls for compact and lighter design and necessarily for tighter tolerances in manufacturing to give better result and longevity of product under continuous running at elevated pressures. Surface clearances like 3-5 microns are now becoming common in many products which are brought in market with higher capabilities. To cater for such fine tolerance zone and without damage to the productstructured design, the oil used must be very correctly selected ,monitoredand maintained with perfect contamination control.” Explains, Sagar Chadala- Executive Director, Concord Hydraulics.

Oil is tested by its manufacturer in many ways –namely for its viscosity, operable temp.range, solid, liquid and gaseous contamination available prior to dispatch, its anti-oxidation property, anti-foaming property.

But when it comes to support the hydraulic system at its end user’s equipment, the only way to control its health is to use a proper filter at proper location, of proper size, and of proper type and propermicronic filtration capability.

To monitor the health of oil following methods are used –

- The colour of oil is a direct visual information to user to indicate contamination. Darker the oil colour , higher is the contamination.

- The viscosity of oil can be checked sending the sample to manufacturer or laboratory.

- Amount of solid contamination available in the oil can be easily monitored by using Particle counter machines or patch kit sampling devises which are available in many designs or can be custom built or Taylor made for specific application.

Particle counter machines are the best solution to check, continously monitor and maintain proper oil condition to run the system for a long time without failure.Contamination to even 3 microns size can be detected in these machines and the values of actual solid contamination nos. obtained in 5 micron/10 micron/15 micron size from oil can be used to produce its ISO grade which is internationally accepted and implemented by all users, designers, manufacturers and consultants .In comaring results of oil samples taken and checked for its ISO grade from time to time, can maintain the system health to its best ,as it maintain the oil condition to required tolerance limit and grade.

90 per cent OF failures in hydraulic systems are attributed to contaminated oil ,and today’s industry has fine micronic graded, high pressure and advanced filters to safeguard oil,to reduce down time, reduce maintance costs and to get higher productivity from machines.

Proper sampling of oil from various locations in oil hydraulic system can give a proper health record of oil, viz-a-vizwell maintained overall hydraulic system health .

Automation technologies in place to tackle common service and maintenance tasks

Hydraulic system’s health and its continuous and smooth running is a completely predictive term today, and not like what happened in the past when the hydraulic system is considered to be leakage prone, unsafe and nonproductive operating system, with certainty of failure at any time and moment.

The same stands true even today, if some basic conditions of operation are not monitored and maintained .They are as follows:

- Common servicing and maintenance task in hydraulics is mainly related to cleanliness of system fluid – oil. Oil is kept clean in hydraulic systems by using proper filters. Once the filters are selected and properly place in the system, the next task is to check their health periodically so that they work diligently to keep oil clean.

- Automated particle counter system or online oil monitoring system is an answer to it.This system can be hooked to any hydraulic system and programmed to give periodic oil sampling tests and diagnostic records to see how the oil is contaminating and also kept clean. This reduces cost of maintenance drastically.

- Other Automation technologies employed are to monitor oil level in the tank, and on reaching the min. acceptable set level for min. oil in tank, the alarm is sent to operator as well as the control PLC or system to stop or trip the system to avoid further damages to important hydraulic products like pumps etc.

- Another technology employed is to monitor and take proper care of oil temperature. Systems are equipped with water or air to oil cooling circuits or are provided later once the rise in temp. is established and data record reveals that oil cooling is necessary. Many oil hydraulic systems have inbuilt programmed temperature signaling to start or stop water or air supply for cooling oil.

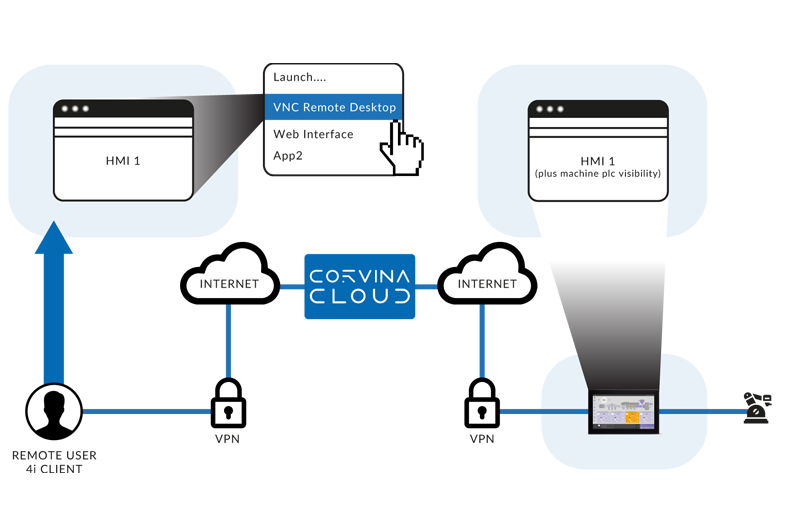

- Today Internet of things are coming in big way with digital technology platform to enhance the predictive and progressive maintenance mode for online monitoring of health of system to operate with zero downtime. This necessitates for the new products, sensors,bus systems to connect all the product for data logging techniques and using the appropriate data for maintaining and servicing of system.

- Many software driven systems are in market to pick up the data from hydraulic system like oil level, temp, pressure, noise etc. Which can be converted into electrical values and are transmitted to the mobile app. To reproduce the result in exact physical values of the entity measured to give the person or service station, who may be away from the system ,the exact nature of working parameters on his desktop or hand held mobile devise like phone or pad.

- Noise level in hydraulic system is also very annoying and safe and silent systems are always welcome to enhance environmental condition around the system where persons are working. Monitoring noise from 1 meter distance and recording the noise level of pump is also considered important to know health of it and to judge longevity of major maintenance breakdowns. Pump is the heart of any system and to safe guard its working and life, this small but important monitoring is an essential requirement and can be embedded into automation system for periodic maintainance.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.