Adiprene LF enables injection molding of cast PU elastomers

August 7, 2019 1:01 pm

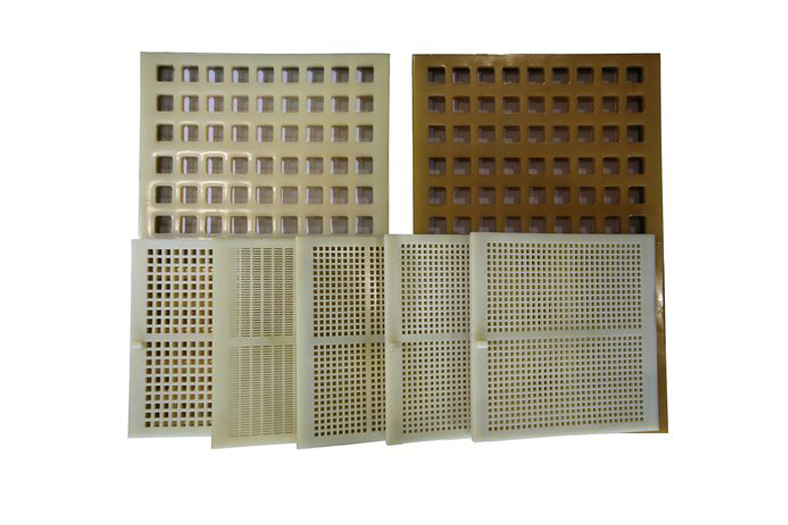

Adiprene C930, a unique Low Free MDI based cast urethane, from specialty chemicals company LANXESS, has just proven as an appropriate material for being processed via injection molding. The Korean company Autox, developed a production process that allows cast polyurethane to be injection molded. This innovation brings a new perspective to the cast polyurethane (CPU) world, as it combines the processing advantages of injection molding along with the properties of cast urethane. Autox has recently launched a new vibrating screen for the mining industry which is made from this Adiprene cast PU prepolymer by injection molding.

Advantages

One of the benefits in working with C930 injection molding, is the high production output rate that makes the process highly efficient and cost-effective. More parts can be manufactured in a limited amount of time and with a single mold. As an example, the current production time of an injection molded mesh screen is five minutes, while the pour casting process will normally take 35 minutes to manufacture the screen. Adiprene LF (low Free) prepolymer delivers improved industrial hygiene, along with ease of processing. It offers a perfect fit with the injection molding process, as the viscosity is lower than of a conventional prepolymer.

Increased life span and screening efficiency

Vibrating screen mesh is a highly demanding application, needed to withstand the challenging mining operation conditions. The Adiprene C930 allows less downtime in the mine operation, leading to maintenance savings. Results of this caprolactone based technology, have been supported by field testing and it has been proved that the lifetime of the screen can be up to three times longer than the market high quality reference.

s

The injection process answers one of the main concerns of the industry: waste management, as it also allows for better quality consistency, leading to less trimmings but also less waste from reduced scrap. While Autox and LANXESS with its Adiprene C930 source material have proven that great achievement can be made on injection molding polyurethane for mining screen, both companies are confident that others applications can also benefit from this development.

For more details, visit:

http://press.lanxess.com

http://globe360.net/broadcast.lanxess

http://webmagazine.lanxess.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi