Robotic process automation: Different means to the same end

August 13, 2018 2:17 pm

A report on how Robotic Process Automation (RPA) makes the traditional automation obsolete

Robots have been around since the 70s and in recent years have seen tremendous accelerated growth. According to research, global market for robots is expected to further increase. Asian market is seen as a major driver for this growth with usage of robots having a projected growth of tripling in coming years. Transitions are always difficult and challenging and it is important to adopt them with an open-mind. These transitions have to be looked at as evolutions and not revolutions. Similar to the previous witnessed transition, the advent of cobots serves as the next step in future evolutions to come. However, with new evolutions in technology the existing technology does not become obsolete.

Re-skilling of work force: An important aspect

Today, if one visits any factory anywhere across the globe; one would find decade old installations. Everyone wants to have smart factories but to change the entire setup overnight is not advisable and not logical. Thus, these systems have been operational and will continue to be operational; however, factories will look at making the existing setups smart with some add-ons. Ninad Deshpande, Head- Marketing, B&R Industrial Automation, says, “The robotics process automation does not render conventional automation obsolete. In addition, re-skilling of work force is an important aspect, which needs attention from the manufacturing units to effectively leverage these advancements.”

RPA: Another IT software, unlike the traditional tools

Meenu Singhal, VP Industry Business, Schneider Electric India, says, “The development of robotic process automation (RPA) technology has come a long way. RPA has become one of the potent technologies when deployed smartly, could lead to significant productivity enhancement and resultant reduction in costs.”

While RPA is yet another IT software, unlike the traditional tools which are deployed first and all exceptions are handled with human interventions, RPA has in-built Artificial Intelligence (AI) and machine learning capabilities. Thus, the repetitive, laborious, ‘no value adding’ tasks in functions such as finance, customer relationship management, procurement or insurance could be taken over by RPA by triggering actions, manipulating data and communicating with other software systems. RPA can turn huge volumes of structured and unstructured data and facilitate the management to take data-driven decisions. He adds, “With the help of RPA, organisations can also monitor the behaviour of personnel and software applications in their business or IT processes-like data extraction and data entry processes.”

Improves performance and reduces operational costs

RPA has evolved significantly over recent years. When applied with systematic planning, RPA substantially improves performance and reduces the cost of operations. Manish Walia, Head – Industrial Automation Business Group, Delta Electronics India Pvt Ltd, informs, “No doubt that RPA has an upper hand over the traditional automation as it can help carry out high volume processes, works on structured data and are human as well as system-triggered. RPA is a very much system agnostic, but traditional automation is not getting obsolete anytime soon in a developing country like India.”

RPA leads to easier crowd sourcing and faster design process

Manufacturing Industry 4.0 requires different skills than those of traditional manufacturing. Robotisation and automation change the nature of processes and procedures in industry and can result in jobs being eliminated. But contrary to conventional wisdom, moving to Industry 4.0 creates high-value-added jobs. Employees have more autonomy in quality control and managing complex manufacturing processes. In a word, innovative manufacturing employees are more qualified.

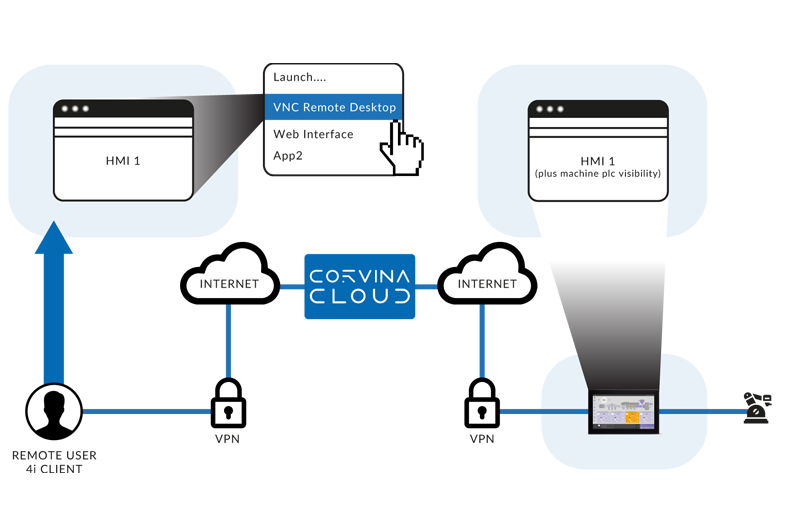

In a world of increasing market volatility, shorter product life cycles, higher product complexity, and global supply chains, companies are seeking to become more flexible and responsive to business trends. Varun Arora, National Sales Manager, Exor India Pvt Ltd, informs, “The Industry 4.0 vision provides recommendations how companies can ease these challenges: the RPA of the whole product lifecycle will allow companies to use data from production, service, and social media which will lead to faster product improvements. Smart items will bring stronger integration of top floor and shop floor; and thus, more intelligence and flexibility to production. With these technologies, companies can react faster to demand changes and implement new configurations easier or even re-plan production much faster.”

He added, “Today’s consumer’s demand individually made products and services (‘Made-for-Me’). smart items, products and machines will enable manufacturers to get down to lot size one and produce customised products without extra cost. RPA will lead to an easier crowd sourcing which will lead to a faster design process.”

RPA vs. Traditional automation

Sanjay Kulkarni, MD, Pilz India Pvt Ltd, says, “RPA is an emerging technology and market is still waking up to its potential where as traditional automation is decades old technology. Traditional automation is usually done to reduce repetitive tasks. It requires a long time to implement where as RPA is usually graphical and requires lesser time to implement.”

He adds, “Traditional automation is better suited for tasks such as simple calculations, linking one system to the other, to maintain low operating costs and simple handling. RPA might take over traditional automation in many tasks but it’s hard to make traditional automation obsolete completely because of these factors.”

Reskilling of work force is an important aspect, which needs attention from the manufacturing units to effectively leverage these advancements.

Ninad Deshpande, Head- Marketing, B&R Industrial Automation

RPA has become one of the potent technologies when deployed smartly, could lead to significant productivity enhancement and resultant reduction in costs.

Meenu Singhal, VP Industry Business, Schneider Electric India

RPA is very much system agnostic, but traditional automation is not getting obsolete anytime soon in a developing country like India.

Manish Walia, Head – Industrial Automation Business Group, Delta Electronics India Pvt Ltd

RPA will lead to an easier crowd sourcing which will lead to a faster design process.

Varun Arora, National Sales Manager, Exor India Pvt Ltd

RPA might take over traditional automation in many tasks but it’s hard to make traditional automation obsolete completely because of these factors.

Sanjay Kulkarni, MD, Pilz India Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.