DMG MORI Solutions for the Aerospace Sector

July 14, 2018 10:19 am

Average growth rates of over seven percent makes aerospace one of the global growth branches. DMG MORI supports OEMs and suppliers with productive manufacturing processes; thus, participating on a disproportionally high degree in the growth of this sector. In order to meet the high requirements of demanding users, DMG MORI concentrates its entire expertise in the DMG MORI Aerospace Excellence Center and offers its customers far more than simply excellent high-tech machines and outstanding technological performance. Their experts are being involved in the future projects of customers at an ever earlier stage, resulting in the development of optimum manufacturing processes and complete turnkey solutions.

“DMG MORI Aerospace Excellence Center supports its customers from the feasibility analysis to profitability assessments and on to machine installation including customised application technology and an extensive after-sales service. The time scale here, from the first enquiry until acceptance of the project, can take anything up to two or even three years. Our service commitment applies equally for the entire DMG MORI portfolio; of course – from turning and milling to the integration of technologies and on through to include ultrasonic, lasertec and additive manufacturing,” informs Michael Kirbach, Head of the DMG MORI Aerospace Excellence Center.

DMG MORI’s ambitious growth targets require a dynamic market. But air traffic is booming and so, is the sale of aircraft. Leading aircraft manufacturers such as Airbus and Boeing, for example, expect the aircraft fleet to more than double by 2036. A large passenger plane is made up of over three million components. Capacities must, therefore, be expanded enormously if this demand is to be met. In contrast to its competitors, DMG MORI covers by far the majority of the different workpieces with its manufacturing solutions.

The machine tool manufacturer also benefits from the work in the DMG MORI Aerospace Excellence Center on a technological level. “Due to the fact that our experts are involved very early on in the development of customer products, we gain a lot of important experience as well as extensive knowledge. Both are incorporated directly in the development of new machines and components in close dialogue with the design engineers in the DMG MORI production plants – for instance where it is a question of efficient machining of special aerospace materials. We have been pursuing this strategy consistently for over 20 years,” explains Michael Kirbach.

Lightweight construction is the dominating topic

Aircraft are getting lighter and more efficient, particularly due to new materials. New materials, in turn, open up undreamt freedoms in the design of components. The structural parts of aircraft contribute greatly to the total mass, so there is an increasing tendency to use CRP and titanium for such parts in addition to aluminium. The low density of the materials plus their high degree of stability enables advanced geometries such as thin-walled components, for example. This also applies in the construction of engines, where titanium alloys and especially increasingly heat-resistant nickel alloys play a key role.

Aerospace speedMASTER 30,000

The topics speed, acceleration und jolting are decisive for aluminium. The machines in the DMC H linear series for horizontal machining with their steeply angled interior covers and open-bottom machine beds enable direct chip fall. Combined with high-pressure cooling and the right machining strategy, this results in a high level process stability, longer tool lives as well as optimum heat dissipation and surface qualities of the machined parts. Michael Kirbach sums up “In a nutshell, we offer an ideal complete package for the machining of structural components made of aluminium: highly dynamic linear drives with 1 g acceleration for more complex geometries, our swivel rotary table and our newly developed aerospace speedMASTER 30,000 for up to 8 l/min metal removal rate for aluminium.

Gantry series expanded

DMG MORI has developed the Gantry series for the dynamic machining of larger components. The DMU 200 Gantry impressively combines the machining of large parts with maximum dynamics with workpiece weights up to 10,000 kg and 0.5 g acceleration. The DMU 600 G linear has a work area of 6,000 x 4,500 x 2,000 mm making it predestined for large integral components. With regard to component size, the DMU 340 Gantry operates with a work area of 3,400 × 2,800 × 1,250 mm between the two sister machines – whereby, the machine can be expanded to up to 6,000 mm in the X-axis and 1,500 mm in the Z-axis.

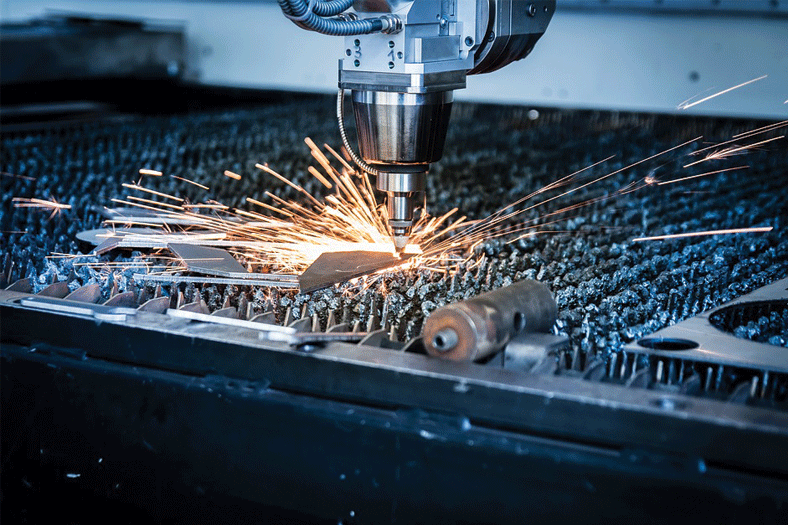

Efficient milling with ultrasonic

The fibre structure and hard-brittle property of CRP materials present a challenge for every type of conventional machining. That is why ultrasonic-supported milling is the answer here. The additional oscillation of the tool with up to 10 µm and 20 to 50 kHz mean higher cutting speeds can be achieved with lower temperature impact. At the same time the fibres are cut better and this adds up to a reduction in fibre splitting and delamination. The formation of built-up edges on the tool due to the adherence of carbon fibre powder is also prevented.

Sturdy machine design for the machining of titanium

The machining of titanium requires maximum rigidity and performance. DMG MORI relies on its duoBLOCK machining centres for high-speed milling with five axes when it comes to the production of complex titanium components, such as landing gear components of aircraft. “For over 18 years now, this concept has been used mainly by our customers in the aerospace industry for hard to machine materials and has been consistently further developed in line with the continuously rising demands”, says Michael Kirbach. “Customers even speak of today’s 4th generation as the benchmark, which of course makes us as machine builders especially proud.” From the DMU 60 P duoBLOCK to the DMU 160 P duoBLOCK, the series offers space for a multitude of different component sizes. Their travel paths range from 600 × 700 × 600 mm to 1,600 × 1,600 × 1,100 mm. Added to these are the DMC U models with pallet changers for higher productivity and increased spindle efficiency.

The duoBLOCK concept combines machining performance, precision and dynamics to a unique overall picture. Its rigidity is supported by extensive cooling measures ensuring that the high demands on accuracy required by aerospace customers can be fulfilled in the long term. The spindles available guarantee perfect performance: both the 1,000 Nm and 77 kW powerMASTER 1000 motor spindle and the 5X torqueMASTER with its 1,800 Nm and 52 kW meet the demands of the aerospace industry to the full.

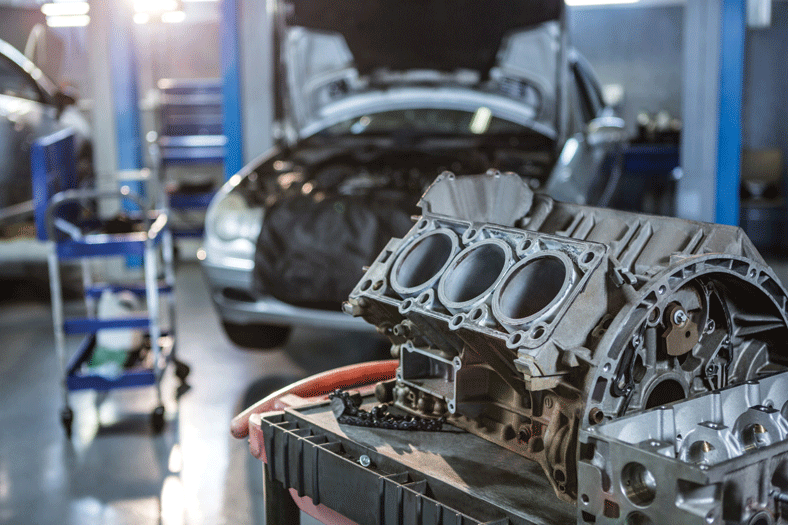

Complete manufacturing in engine construction

“The technology integration of our mill-turn or turn-mill machines opens up the path to the process-stable complete machining of rotational symmetrical engine parts made of titanium or nickel alloys”, explains Michael Kirbach. Leading manufacturers of engines such as GE Aviation, Rolls-Royce, Pratt and Whitney or MTU Aero Engines have in fact been using the FD machines of the monoBLOCK, duoBLOCK and Portal series successfully for milling and turning in only a few setups for 18 years now.

Nowadays, high-precision components can be produced even more productively, thanks to further technology integrations. Even grinding wheels with internal and external cooling can be changed over automatically with the FDS machines. Special DMG MORI technology cycles and structure-borne sound sensing help users with handling the technology. In addition, systems for in-process measurement and integrated process monitoring support the operator on the path to the perfect process.

Michael Kirbach points out a trend towards the use of materials that are extremely difficult to machine, such as ceramic matrix composites (CMC), especially in the field of engine construction. “We have been working on these advanced materials for years. For such applications DMG MORI offers its lasertec and ultrasonic technology.” The focus here is always on expanding and improving conventional manufacturing processes. “It is not only important to be better and faster, but more cost-effective as well, for example, by using ultrasonic to machine even materials such as CMC reliably and productively.”

Digitisation in the aerospace industry

The overall trend in the aerospace industry is towards the integral networking of machines, products and services to digital process chains. DMG MORI is also actively advancing the topic of digitisation with its ’Path of Digitisation’. All high-tech machines, for example, are equipped with the APP-based control and user interface CELOS. CELOS enables consistent management, documentation and planning of orders. In addition, CELOS APPs such as condition analyser or performance monitor provide customers with a detailed view of the machining processes and the status of machines as the basis for a continuous improvement process. CELOS also functions to an ever greater extent as an IoT interface; thus, creating the basis for cross-company interaction in the production networks of the future.

For more details, visit www.dmgmori.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi