The IIoT future is now!

June 12, 2018 3:46 pm

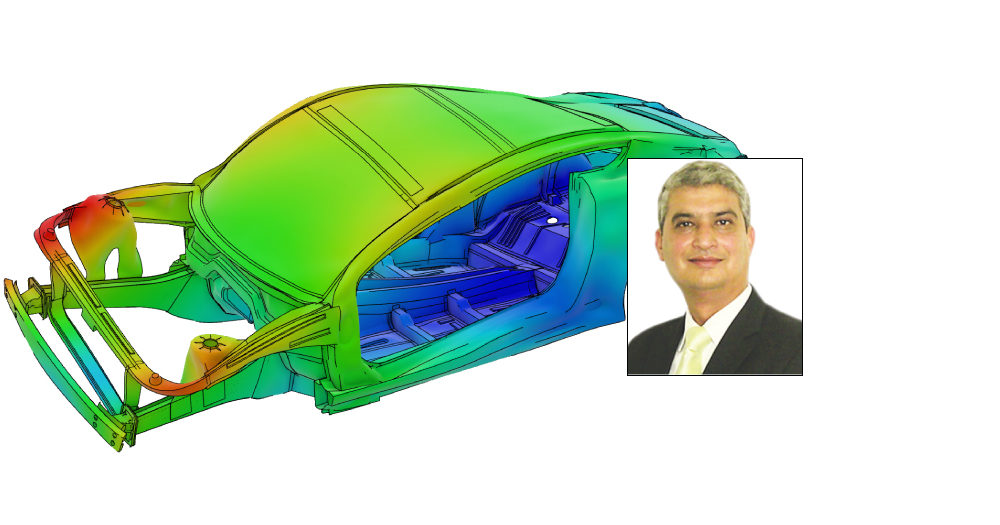

Arun Rao,

Director – Geo Strategic Operations & Alliances, Dassault Systèmes

With an integration of ‘digital continuity’, IIoT helps in creating a unique, authoritative and consistent source of data across the entire lifecycle as a product moves from concept to design, engineering, manufacturing, and post-sales service.

IIoT: Improving safety and efficiency

IIoT is considered as one of the primary trends affecting industrial businesses today. In order to be future ready, industries are pushing to modernise systems and equipment to meet new regulations, keep up with increasing market speed and volatility, and deal with disruptive technologies. Arun Rao, Director – Geo Strategic Operations & Alliances, Dassault Systèmes, informs, “Businesses that have embraced the IIoT have seen significant improvements in safety, efficiency, and profitability and this trend will continue as IIoT technologies are more widely adopted.”

IIoT elevates the making of informed business decisions by utilising the right concoction of planning, manufacturing and distribution information with higher degrees of intelligence, automation, and precision. Rao believes that the technology has strongly impacted the ‘global’ high-tech industry which has been facing rising demand variability and ever-shorter life cycles. He adds, “With an integration of ‘digital continuity’, IIoT helps in creating a unique, authoritative and consistent source of data across the entire lifecycle as a product moves from concept to design, engineering, manufacturing, and post-sales service.”

Dassault Systèmes is constantly working towards enabling high-tech companies with highly flexible manufacturing to achieve all the competitive benefits that IIoT has to offer through digitally integrating manufacturing planning, execution and demand planning on a single platform. The manufacturing industry will be able to accelerate the New Product Introduction (NPI) on a global scale with a very high quality initially and also a faster ramp up by eliminating delays for identification and containment of delays by 80 per cent.

This growth is clearly beneficial for manufacturers — it has been predicted that those businesses who do harness the power of IoT will be more profitable than those who don’t. In the near future, it is also estimated that majority of worldwide manufacturers will capture and analyse data using connected products. Rao explains, “As markets become increasingly competitive, such advantages of IIoT cannot be ignored and this is where the clear-cut advantages of using IIoT in a manufacturing business will come into the big picture.”

Industries that will drive IIoT adoption in 2018

Whether they call it Industry 4.0 or “smart” manufacturing today has changed the focus of experts on how to extract data from intelligent machines and then analyse it to improve both their products and processes used to create them. Organisations are looking into their repository of fixed data under the control of a specific department of theirs or ‘data silos’. Moreover, Digital continuity is the big story today in most industries. Organisations cannot ignore the machine-to-machine communication that might result in a major manufacturing failure. IIoT has been a cure for all of these. From hand dryers to aircraft engines, farmyards to office blocks, there has been a multitude of innovative uses of the IIoT. Yet, sectors such as healthcare, automotive and mining are conducting production-focused test cases and large-scale projects more so than others.

The increasing interest from pharmaceutical companies, a sector which is becoming more competitive, even for well-established mainstream products, is contributing a lot to the IIoT adoption these days. In this industry, if a manufacturing line stops or the product line needs a change, the entire line has to be completely re-certified from start to end, including the software, to comply with FDA regulations and this is where the IIoT comes into the picture.

In the mining industry, the efficiency of production can be improved by enhancing the interaction of its different processes by employing a business platform that bridges the gap between Information Technology (IT) and Operational Technologies (OT). Thus, to integrate information received from the OT and IT it is essential to deploy an enabling platform that collects data from across the operation, delivering it where and when it is needed to the decision makers, in the right context. IIoT helps in merging of these systems that further provides management with higher confidence in operational performance as critical decisions are made using real-time data.

As the Industry experts, the automotive industry recognises the challenges of legacy systems. Rao explains, “The role of IIoT comes in with the cost and investment factor to the constantly changing significant system. IIoT helps identify the real areas of opportunities that technologies today can deliver. However, the issue lies in the way uses the data coming in from the field not just for cost adjustment and accounting, but back into the component development process. This is where the story of IIoT adoption comes in, and it definitely is going to prove itself as a game-changer in 2018.”

Dassault’s preparedness in the area of IIoT

With IIoT now on the rise, Dassault Systèmes’ highly flexible manufacturing enables high-tech companies to fully integrate the IIoT opportunity through the digital amalgamation of manufacturing planning, execution and demand planning on a single platform. It delivers the production speed and agility required in today’s competitive and cost-sensitive markets.

Digital continuity provided by the 3DEXPERIENCE Platform integrates the information contained in all the phases right from product creation to product operation and support. Pairing the real world data with scientifically accurate 3D models of the product- with the help of IIoT, Dassault Systemes monitor the real-time environment and predict its future state before it can further go in for 3D printing, thereby reducing cost all the more.

Since the number of industries that Dassault Systèmes delves into is very major, IIoT will eventually imbibe the much needed digital continuity which will further accentuate all the benefits that IIoT has to offer.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.