Online configurator for lead screw modules fulfils millions of design variations

January 15, 2018 4:57 pm

A few clicks will take you to the custom-made lead screw module with the new configurator from igus

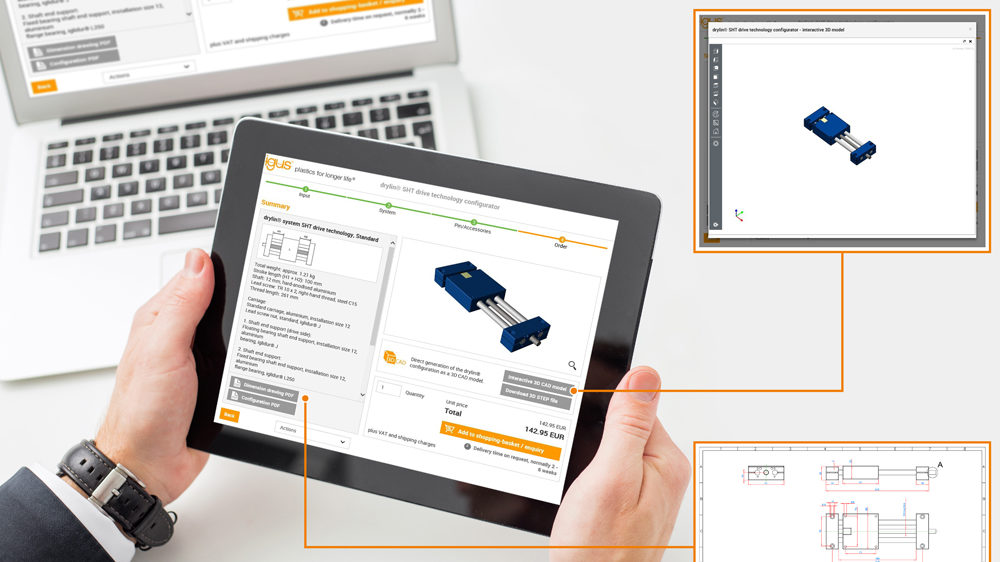

The motion plastics specialist igus has developed a completely new online configurator for drylin lead screw modules. This allows the customer to easily design and process millions of different variations of lubrication-free drylin lead screw modules according to one’s requirements. As user, you will receive, among other things, a 3D view of the unit and a dimensioned technical PDF drawing as well as a 3D CAD model with which you can immediately plan the implementation of your project before receiving the product. With a click, you can order the unit at igus. The weight, the delivery time and the price of the assembled parts are displayed automatically.

The design and configuration of a lead screw module (SHT) often takes a lot of time and effort for project managers. In order to optimise this process, igus has developed the new lead screw module configurator for its customers. With this, all ready-to-install lead screw modules from installation size 08 to 30, including the new SHT series made entirely of stainless steel, can now be designed quickly and above all easily, including the preparation of the technical drawing. Just a few clicks are enough for placing the online order for the individual product. “Step one, the user determines his/her environmental parameters, the desired lead screw and thread type as well as the material of the components,” explains Stefan Niermann, head of the drylin linear and drive technology division at igus. “In the next steps, it is possible to configure the carriage type as well as multiple slide systems as well as the drive shaft as desired. The customer can modulate these shafts according to their requirements. Spanner flats and grooves in different tolerance classes and desired lengths are quickly designed.” After the design, the user is presented with an overview page showing the unit price, the weight and the delivery time of his/her table, and a summarised list of the installed components. Here

an automatically generated 3D model and a 2D dimension drawing can be displayed and downloaded free of charge.

Process optimisation through online configuration

With the technical drawing and the CAD model, the customer can continue to work immediately on his/her project and digitally share the plans of the lead screw module with other project participants quickly and easily. After completing the configuration, the individual lead screw module can also be transferred to the shopping-basket and ordered without minimum order quantity or a request about the products can be sent to igus. It is also possible for the user to save, load or completely reset the configurations. For example, revisions to the lead screw module can be undertaken quickly and easily due to project alterations. Following an order, all specifications on the product will be sent to igus. Thanks to the digital data transmission of this information and drawings, the order is directly sent to the factory and can be processed, assembled and often delivered within 48 hours even for complex configurations. The personalised product thus becomes a simple standard. The use of the configurator not only optimises the ordering process for the customer, but also for the internal production processes, which results in a shorter delivery time.

The new drylin SHT configurator can also be easily operated via the iPad and can be found at: www.igus.eu/drylin-sht-configurator

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.