Digitisation is key to higher profitability

June 29, 2017 5:29 pm

There is urgent need for top and middle level management to consider and focus on digitising their products, processes and manufacturing technology aggressively.

Today, information is the key to business success and profitability will come through digitisation of manufacturing processes and enhanced manufacturing efficiencies, said Ajey Phatak, Marketing Manager, Beckhoff Automation Pvt Ltd. However, he observes, implementing Industry 4.0 or digitisation requires standardisation and CAPEX provisions.

Importance of digitisation in manufacturing process

Digitisation and vertical and horizontal integration of machines and systems, digitisation of products, services, supply chains and integration of customers and vendors are at the core Industry 4.0.

The contributing technologies like OPC UA, real time Ethernet Fieldbus communication, PC based control and automation systems, smart sensors, smart HMIs, cloud computing IT solutions, Mobile devices, networking technologies, machine learning, condition monitoring and big data analytics are thoroughly integrating the industrial manufacturing activity. In today’s complex economy, information is the key to business success and profitability will come through digitisation of manufacturing processes and enhanced manufacturing efficiencies.

Strategic initiatives

The Indian industries are no doubt extremely enthused about the buzzword IIoT or Industry 4.0 and are initiating projects. But majority of Indian industries especially local manufacturers and SMEs need to view and understand the core of this technology concept and attempt to increase efficiencies of their manufacturing activities plants and businesses.

Implementing Industry 4.0 or digitisation requires standardisation and CAPEX provisions. Projects need to bring all machines and assets and its vendors on board the horizontal communication platform and invest in IT solutions for analytics. This calls for proactive support from all machine vendors and system integrators.

Industry 4.0 is all about connectivity. Understanding networked machines, real time Ethernet Fieldbus communication and its direct relevance to Industry 4.0 is essential. There is urgent need for top and middle level management to consider and focus on digitising their products, processes and manufacturing technology aggressively. Further IT department have to play a very important role in future of manufacturing and cannot remain isolated. Moreover boardrooms have to take a strategic CAPEX investment call for implementing Industry 4.0.

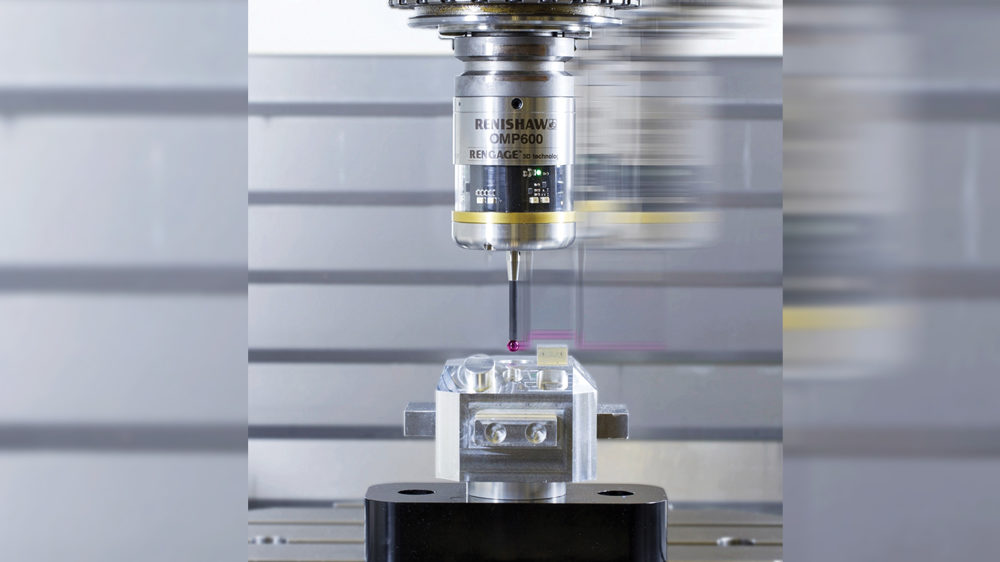

PC-based control adds value

On the one hand with Beckhoff offers all basic technologies and components available for PC-based control systems – from PLC to robotics through to measurement technology and on the other hand with the comprehensive product portfolio designed for “Integrated Industry” Beckhoff PC based control technology benefits increased production efficiency as well as machine and system optimisation through advanced functionality. The new universal Industrial PC for automation, visualisation and communication tasks, new Embedded PCs of the CX20x2 series Beckhoff provides many-core processing power on the DIN rail, the EtherCAT measurement modules all are designed for building control and network infrastructure for smart factories.

Focus on seamless integration

In order to realise Industry 4.0 following a genuinely holistic approach, three aspects have to be implemented: horizontal integration across company boundaries, vertical integration through networked production systems, and integrated engineering throughout the product lifecycle. PC control offers the right solution for all of that, especially since it can be adapted very flexibly to varying application requirements: intelligence can be arranged in a hierarchically modular fashion under the central controller, but also decentralised, i.e. with equal rights if necessary.

In addition, there are hardly any technical systems today that cannot be operated by PC or at least be connected to a PC via software. Considering the great variety of manufacturing systems and technologies that are used in industrial enterprises, the key role of PC technology as an open platform and de facto industry standard for automation is obvious. The openness and universality of PC control can also be seen – entirely in the sense of Industry 4.0 – in current research work for the seamless integration of information areas.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.