Yamada AODD pump ensures safety in API manufacturing process

June 29, 2017 11:29 am

We found A.T.E. to be a very reliable flow technology solution provider. We are very happy for the solution provided in API process technology with Yamada AODD pump. We are going to replicate this solution in other units of Cipla.

Ajit Patil,

API manufacturing, Cipla Ltd

API manufacturing is one of the most critical processes in pharmaceutical industry. The first step in API process is the raw powder transfer to the API reactor. When raw powder is manually transferred, there is a risk of static generation, which may cause fire or explosion. For Cipla, however, this is no more a problem – thanks to the effective solution provided by A.T.E.

Background

Cipla Limited is an Indian multinational pharmaceutical and biotechnology company, headquartered in Mumbai, India. It is a pioneer in API manufacturing in India for over 5 decades. Cipla currently manufactures more than 200 generic and complex APIs and has a network of modern API manufacturing facilities; all approved by the USFDA and other major international regulatory agencies.

Challenge

The production process at Cipla involved transferring certain powders from the raw material storage into the API reactor. Earlier, the material was transferred manually at a rate of 50 kg/hr. However, the manual transfer of raw material is a hazardous process, posing the risk of static generation, leading to fire and explosion. Also, the time consumed for manual transfer of raw material from storage to API reactor is long.

Solution

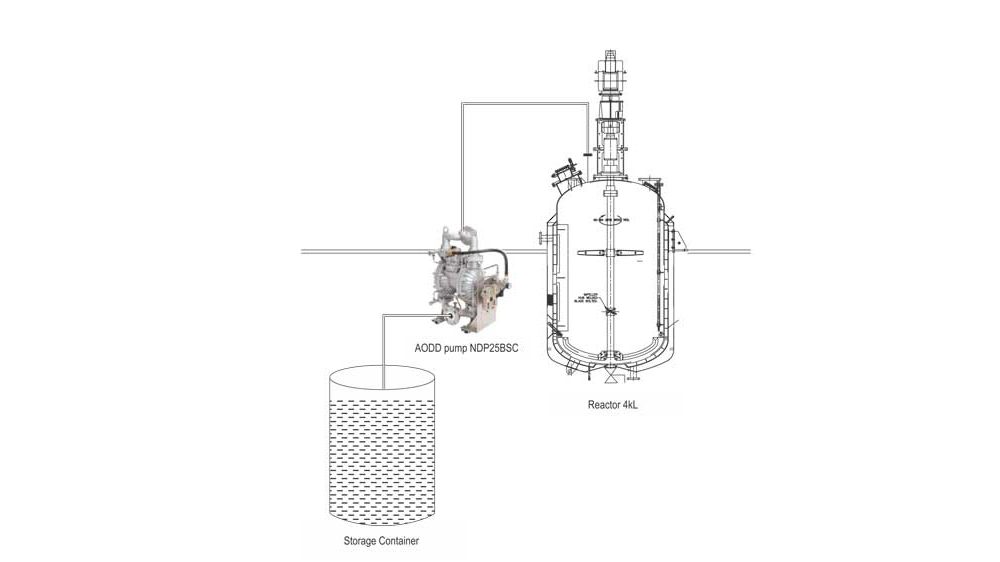

After understanding clearly the process of the customer and the problems faced, A.T.E. engineers visited the site and calculated the pump capacity and other parameters based on the operating conditions. Based on A.T.E.’s recommendation, a specially designed Yamada AODD pump was installed at one of the API rector for transferring up to 4 different types of chemicals in powder form from the storage to the reactor. In the trial that was carried out, the Yamada AODD pump transferred the material at a rate of 100 kg/hr (the pump is designed for transferring raw material at a rate of 200 kg/hr) at 3 kg air pressure, without any hindrance. After a batch was completed the pump was flushed and found to be clean, without any internal deposits, which showed that all the powder was successfully transferred. Also, with Yamada AODD pump the raw powder transfer happens in a closed operation under nitrogen blanket and hence there is less exposure to environment and thereby lower risk of fire or explosion.

Result

• Safety: Closed operation under nitrogen blanket, hence, no chance of fire or explosion

• Trouble-free operation: Works smoothly for powder transfer application without any choke up, and hence, less maintenance

• Saves time: Up to 50 per cent reduction in powder transfer process time.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.