How predictive maintenance saves money

May 12, 2017 12:49 pm

Here’s a deeper look at how predictive maintenance can be essential in saving energy, time and money.

Predictive maintenance plays a very crucial role in today’s time. It uses the technologies to assess the state of equipment and forecast failures before they happen. In short, preventive maintenance helps the job strategy to be performed on a stipulated period of time.

Predictive maintenance is effective

Any capital equipment is purchased and installed to generate productive output for a defined period. “The equipment cost contains two parts – the fixed or acquisition cost, which includes the cost of the machine itself and the cost of commissioning it. The second part is the cost of running the machine – cost of consumables, wastage, bad products, cost of regular maintenance. The cost of production per piece has factors from both of the costs – the initial layout and the running costs. It is also strongly determined by the volume of production achieved. Higher the number of pieces produced, lower will be the cost-per-piece,” says P.V.Sivaram, Managing Director, B&R Industrial Automation.

More than just purchasing new machines, plant and factory operators even, evaluate the cost of purchasing, operation and the cumulative cost over the entire useful life. In addition to this, maximizing machine availability and minimizing time and money spent on maintenance is the best strategy to decrease production cost per piece.

Speaking about the old traditional way of maintaining machines, Sivaram says, “It is necessary to keep spare parts handy, and when a break-down happens quickly work to get back the machine on line. This obviously has downtime. So, over and above this, a cyclic periodic scheduled maintenance could be added. Here we catch the parts before they fail, because of a statistical average life assigned to the. Again, the disadvantages are, we may be replacing parts before they are due, and we are forcing downtime when not needed.”

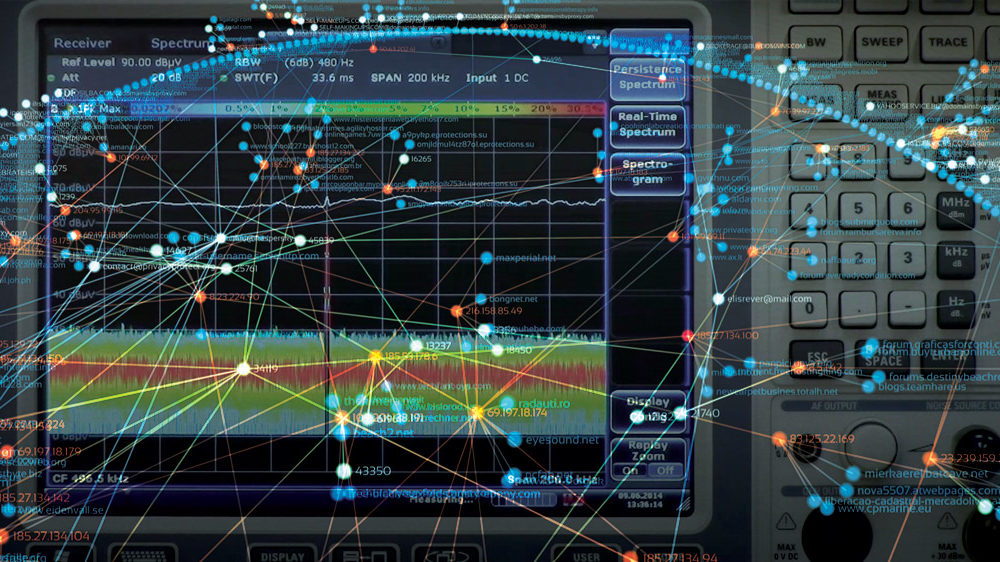

In today’s time, condition based predictive maintenance is effectively deployed by many machine operators to predict machine and system failures before they happen to reduces costs and increases availability. He further stated, “Condition monitoring system provides accurate information of wear and tear enabling plant operators and machine builders to use components under check to the fullest. Machine operators can also benefit from the integration of condition monitoring with a company’s internal logistics systems. When the machine identifies the need for maintenance, for example, it can automatically trigger a reminder to the maintenance or purchasing department for the required parts. This prevents orders from being overlooked or placed incorrectly and ensures that the right part is on hand when it is needed without having to maintain a large stock on site.”

While talking about the maintenance, it’s not the only area where having live, preprocessed condition data opens up new possibilities. Sivaram says, “Recorded condition data can also be fed into automation software to provide additional functionality such as adjusting the speed in order to extend the time before maintenance. This kind of adaptive operation can further contribute to increased availability and a longer service life – which in the end means more efficient resource utilization and lower unit costs.”

He further adds, “The best way to optimize the ratio of machine availability to maintenance costs is to replace the fixed maintenance intervals with condition-dependent, predictive maintenance. This involves scheduling maintenance when changes in monitored parameters indicate impending failure. The advantage of this is that components can continue to provide value until much closer to the actual end of their useful life, which is typically much later than the conservatively estimated maintenance interval. Yet there is no sacrifice in planned maintenance schedules since the required maintenance can be performed during regularly scheduled breaks in production. The risk of maintaining a stock of replacement parts is also minimized since only the affected components need to be replaced. This is also a way to reliably avoid failures that result from neglected maintenance.”

As per Sivaram, it is very important that such systems need not be standalone units as it will start increasing the machine & plant cost and could be a deterrent for installation of such systems. Thus, installations of such systems need to be integrated with energy monitoring and data acquisition systems. With B&R, customers are able to use a single system for process data acquisition, energy monitoring & condition monitoring and that too using standard component. Condition monitoring modules from B&R precisely detect cases when service work may be needed and are also extremely easy to configure. In a demanding market as the automotive industry, “All of these modules are part of the X20 control system series and can therefore be used in any control topology with no limitations. A special feature of these modules is that they perform vibration analysis locally, right on the module,” says Sivaram. Apart from this, the availability of fully processed results reduces the time and cost of integration to a minimum. These results also provide detailed insight into the system mechanics, allowing existing processes to be optimized with maximum efficiency.

Predict and rectify before it hurts

“A stitch in time saves nine – It’s always been a wise decision to go for a predictive solution for a situation before it becomes a problem. Predictive maintenance is widely anticipated in industrial applications as it not only reduces the maintenance costs by maintaining the process equipment before failure but also reduces the costly downtime,” says Mukesh Thakur, Assistant manager – Sales & Marketing, Finder India Pvt. Ltd.

He further adds, “The output quality time of the process and the workforce output gets prevented from being wasted. Keeping predictive theory in mind, most of the System Suppliers have started adapting to advanced warning systems i.e. Asset Management tools and on the other hand Component Suppliers have stated integrating diagnostic features i.e. development of new generation SMPS power supplies which are capable of predicting in advance the abnormal control system conditions which if not addressed give rise to system failure etc.”

To top it all, Thakur says, “The advent of IIoT has further taken the predictive maintenance to the next level, wherein conditions of various control and automation components including sensors and actuators are monitored remotely via the cloud and the maintenance teams get the timely inputs thereby providing ample reaction time to rectify the problem and reduce unexpected shut downs. These kinds of features are getting more popular in the applications where the Control Systems are not within a controlled environment.”

Thakur also belives that the role of predictive technology can be easily be integrated in the existing plant and machinery as well. Moreover, technologies are now available which can ease the life of maintenance engineers by incorporating simpler user-friendly components like voltage monitoring relays, thermostats, hygrostats, current sensing relays, thermistor relays, safety relays etc which can easily be installed and programmed to give advanced diagnostics for an existing control system against any kind of pre-mature failures.

Be proactive instead of reactive

“Preventive Maintenance is undertaken by a company to avoid any occurrence of unexpected failure at a product-life cycle. With intense worldwide competition and a risk of financial failure, companies are looking forward to ease the burden and strengthen their market position. Preventive Maintenance helps to boost the product availability for long term,” says Vipul Gupta, Manager – Application, Factory Automation & Industry Division, Mitsubishi Electric India Pvt Ltd.

Gupta says “It is better to be proactive instead of reactive. Effective measures should be taken for extending service life of the unit.” Expressing more about the following tasks like clean & dust, check-up for lubrication brushing and bearings, replacement of fuses…etc. should be done on a regular basis. In MEI product, VFD’s FRA 800 series, conformal coating is done to save equipment from moisture, dust, chemical and heat, if electronic equipment left uncoated it will result in failure.

When asked about the benefits of preventive maintenance, Gupta says, “It helps to increase production of the company. The cost of repairing or replacing the equipment falls down by applying regular checks-up. Checking for the resistors or capacitors working conditions on a regular basis, helps in saving the repairing cost. MEI product, Low voltage Circuit Breakers helps the machine against the unexpected break downs.”

Gupta firmly believes that, Measures should be undertaken to curb down the unnecessary power consumption, increase efficiency by shorter lead time, and provide optimum energy supply, introduction of high efficiency equipment and reducing idle operations time duration. For instance: Electric Motors should be prevented from dust particles as negligence can cause consumption of more current by the motors which will incur costs to the company.

He also observes that day to day operations can be made more effective by providing beforehand a complete data analysis, instructions, and procedures for the equipment.

Gupta further says, “Through this we have understood the importance of Preventive Maintenance and how it helps in consolidating an Industry.”

Investing in collaborative robots has a significant advantage

“Predictive maintenance is crucial to both large and small scale manufacturing units. Currently, industrial automation and robotics go hand in hand. Manufacturers who invest in Collaborative robots have a significant advantage in this regard. Traditional industrial robots require frequent and heavy maintenance. This is usually done every 6 months at an approximate cost of $1000 annually per robot.” says Pradeep David, Country Head – India & Sri Lanka, Universal Robots.

He further adds, “There is always the option of engaging in an annual maintenance contract (AMC) which excludes spare parts and allows only general servicing viz controller cleaning, battery check, power check, robot greasing and final product testing. An AMC is priced at approximately USD 2500 per robot.” On the other hand, there is a slow shift towards collaborative robotic technology which entails lower maintenance levels in comparison with industrial robots. At Universal Robots, the drive system has the inbuilt grease and it does not warrant a change for the life span of the harmonic gear. Hence, the need for an annual maintenance contract (AMC) does not feature.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.