DISA India celebrates its Customers’ Day 2016

December 14, 2016 12:55 pm

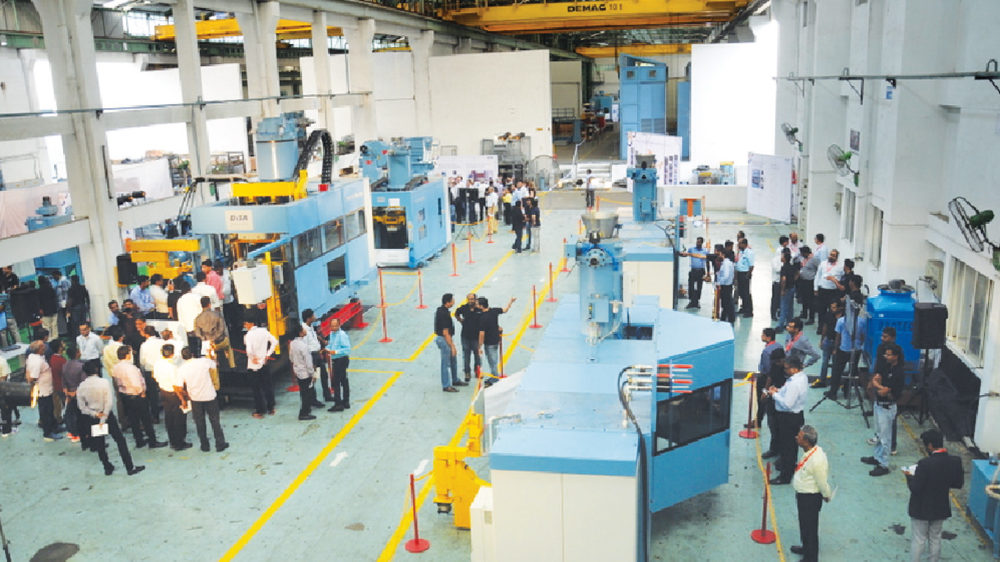

DISA India celebrated its Customers’ Day event on 25th October, with over 160 participants attending from more than 90 companies across India.

DISA’s international agents from 15 countries – who were in India for DISA’s Annual International Agents Meet – also joined for this event leading to a strong inter-cultural and across-boundaries networking amongst the 160 participants.

The profile of the participants included senior management and owners of the foundries and castings units.

Viraj Naidu, Managing Director, DISA India Limited during his welcome note to all delegates said “Our consistent focus has always been to ‘make the top end technology affordable’ for foundries in India – through strong engineering, localisation and unmatched service levels. We believe that this focus is the key to further accelerate the automation trend for Indian foundries.” He continued, “Our belief in our long term focus – on making the ‘high end technology affordable to Indian foundries, through increasing localisation’ – is continuously getting reinforced. The purpose of hosting a Customers’ Day 2016 is to showcase the widest range of foundry machineries and technologies, the unmatched manufacturing facility for foundry solutions in our country and the strength of our DISA and Wheelabrator colleagues – who are globally ‘United through Pride’.”

All green sand moulding solutions (DISAMATIC C3-150 MPH, DISAMATIC C3-250MPH, DISA MATCH 24/28, DISA MATCH 20/24, DISA FLEX 90, DISA FLEX 70HS, DISA ARPA 900) offered from DISA India, were on display along with sand plant equipment, TM-160 mixer, Wheelabrator VH 10/12 shot blast machine, filters for fettling and wide range of castings made on DISA moulding machines. These equipment offer the ideal technological stepping stones for the Indian foundries to upgrade.

The company presented next generation innovations as follows:

New Generation DISAMATIC C3 – 150 and 250 MPH: The company’s DISAMATIC offerings have been producing castings at the lowest cost per casting. Its innovative DISAMATIC C3 – the first DISAMATIC moulding machine ever produced in India – includes high-end hydraulics, and various TPM concepts like visibility while in operation with transparent doors.

DISA MATCH 24/28: Designed and manufactured to deliver high capacity of 120 uncored mould per hour; more precise or maximum machine related mismatch guarantee of 0.25 mm; repeatable and automatic core setting with Automatic Core Setter (CSE); easy and fast pattern change using Quick Match Plate Changer (QMC); high uptime with local availability of parts and service; lower capital investment cost as it is available for sale in rupees in India.

DISA FLEX 90: DISA India’s advanced horizontal flask turn-style moulding machine for foundries wanting a flexible solution for production of high quality, medium and heavy near net shape castings. DISA FLEX combines the unique DISA high pressure, double-blow and hydraulic squeeze moulding techniques with a rigid machine design, giving the best conditions for the profitable production of high quality castings. The FLEX 90 machine comes with flask size of 1300x1000mm and can produce 80MPH.

DISA ARPA 900: DISA ARPA is a jolt squeeze moulding machine suitable for smaller foundries requiring flexibility, good quality production of short run castings. DISA ARPA 900 comes with flask size of 1000x800mm and can produce up to 30 MPH with semi-automatic mould handling system. The ARPA moulding machine comes in 4 different variants 300, 450, 900 and 1300 covering a complete mould range from 500x600mm to 1050x1400mm.

DISA TM 160 Mixer: Delivers unbeatable reliability, precision, durability and cost-efficient operation. Robust design, precision engineering and quality components combine with the latest process control technology to make the DISA Turbine Mixer superior in every way. TM mixers comes in 4 different variants based on their batch sizes and per hour output (TM 160, TM-190, TM-240 and TM-285).

Wheelabrator VH-10/12: Wheelabrator offers a new hanger type solution for foundries. Hanger type blast machines are very flexible solutions and meet jobbing foundry/forging company requirement cost effectively. The only variable factor is the fixture design, which gets modified with respective parts. DISA India continued to focus on these machines and tried to optimize solutions to give customers increased added value. Its key features include: small foot print; pit-less machine; load carrying capacity of 800kgs/hook; high performing wheel (SATURN HD); its safety door is operated through electromagnetic motor, etc. Further, it can install, connect and blast with quick installation time; it is easy to move the machine if the production process changes and has a magnetic separator (optional).

DISA Cartridge Filter: DISA India displayed cartridge filters developed specially for the fettling and grinding applications. The eS range of filters are made with special cartridge design to handle fine metal dust, high energy savings by automatic damper control, VFD controlled fan to save energy, inbuilt spark arrestor to ensure safety, etc. DISA’s state-of-the-art pleated cartridge filters offer global emission standards with very low energy consumption.

Contact:

DISA India Limited

Tele: +91 80 40201400-13

Bangalore@noricangroup.com

www.disagroup.com

www.wheelabratorgroup.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.