Good automation can generate productive environment

August 12, 2016 5:54 pm

India is increasingly recognising that in a competitive, globalised environment, investing in intelligent automation and control systems to optimise manufacturing.

In an exclusive interaction with OEM Update, Rajarshi Datta, Sales Director, Honeywell Process Solutions, India, talks about the emerging trends in automation technologies and how HPS is leveraging the right mix of technologies to ensure the success of automation projects. Edited excerpts:

Intelligent automation to optimise manufacturingIndia is increasingly recognising that in a competitive, globalised environment, investing in intelligent automation and control systems to optimise manufacturing, plant optimisation, and control and process monitoring systems, is the way ahead. Today, automation is a business strategy. Good automation systems with smart remote devices and data analytics built on it can generate a productive environment to ensure proactive decisions during or before a mishap. Honeywell Process Solutions (HPS) provides a comprehensive suite of solutions to make the process industry more productive, and its operations safer, more efficient and more reliable.

Market share and positionA business unit of Honeywell International, HPS has pioneered process automation control for more than 40 years with a continuous evolution from legacy process control systems to today’s leading innovations such as experion PKS, protecting customers’ investments in automation assets.

HPS helps industrial customers around the world operate safe, reliable, efficient, sustainable and more profitable facilities. With more than 12,000 employees around the world, HPS has the global expertise and breadth of resources to execute projects of every size and complexity in the oil and gas, refining, pulp and paper, industrial power generation, chemicals and petrochemicals, biofuels, life sciences, and metals, minerals and mining industries.

Prime offeringsBusinesses in India are increasingly opening up to the possibility of being future-ready. Honeywell has the right mix of emerging technologies that can be deployed at the right time – for businesses that recognise this, these technologies would be key in differentiation.

In India, Industrial Internet of Things (IIoT) will enable transformation of nearly all industries. HPS recently established a new business unit to help manufacturers harness the IIoT and more rapidly deploy technologies that will allow them to better manage and analyze data, making their operations safer, more reliable and more efficient. IIoT by Honeywell technologies involves bringing people, processes and assets together.

Plants and refineries use Honeywell’s safety instrumented system (SIS) platform, safety manager, to safeguard assets and share critical safety information with process control systems. This system helps prevent and mitigate safety incidents by protecting equipment, monitoring for fire and gas leaks, and maintaining critical control functions.

Among Honeywell’s leading technologies that help operators prioritise and manage a growing amount of operational data are DynAMo alarm and operations management; Industrial Cyber Security Risk Manager, which proactively monitors and manages cyber risk for industrial environments; assurance 360, a multi-year cooperative service arrangement to maintain, support and optimise the performance of Honeywell control systems.

Latest additionHPS has been providing solutions and technologies to help manufacturers leverage critical operational data on a site by site basis for years.

HPS recently announced the launch of Uniformance Suite, a new, fully integrated system of process software solutions that turn plant data into actionable information enabling smart operations. The software suite provides powerful data analytics capabilities to enable customers to capture the data they need, visualise trends, collaborate with other users, predict and prevent equipment failures, and act to make informed business decisions.

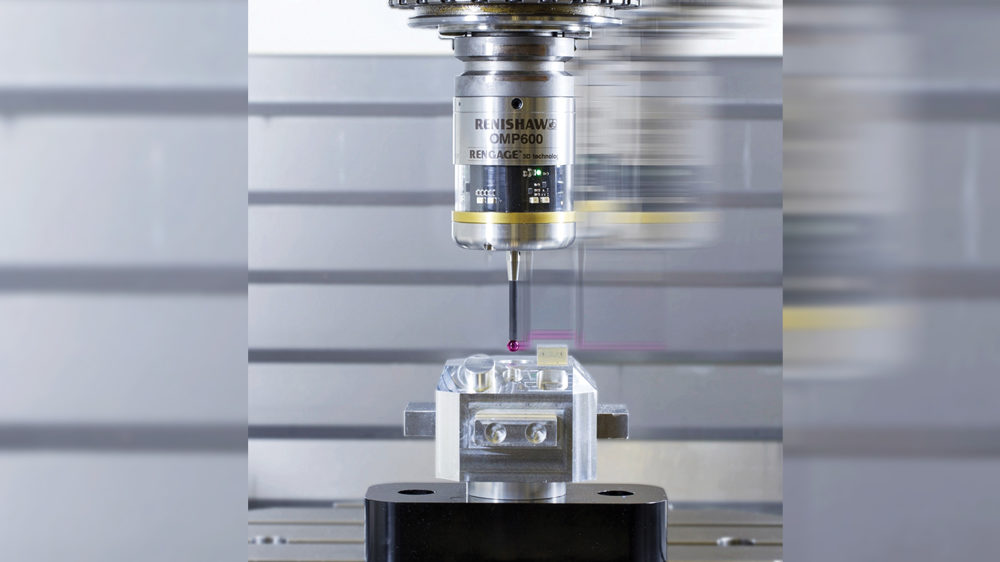

The company has also launched the newest version of Experion Process Knowledge System (PKS) Orion, featuring advanced IIoT capabilities. The new solution will help industrial plants further optimise automation project execution, reduce loop commissioning time, minimise operational risk and protect intellectual investments while keeping current with today’s technology.

Honeywell Pulse is a new mobile app used to remotely connect plant managers, supervisors and engineering staff to customised real-time plant performance notifications sent from HPS’ industrial automation software. It brings relevant metrics and the tools to resolve issues directly to mobile device.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.