Han Docking Frame: A connector for modular energy storage

August 5, 2016 5:13 pm

Supplying power from renewable energies requires electrical storage capability to balance out peaks and troughs in the mains voltage caused by fluctuations in wind and solar generation. Current storage systems provide greater flexibility. They absorb surplus generation and relieve the mains network. The charge they hold also helps to cover short-term peaks in demand. This means that the capacity of (decentralised) generation systems is better used and the network is more reliable.

The storage systems are integrated into intelligent network management systems (smart grid) via a powerful communications structure. They are of a modular construction so that: They can adjust flexibly to different generation capacities Can be configured redundantly. This means that when individual modules fail they can be replaced without interrupting the operation of the system as a whole.

Efficient storage systems generally consist of several storage cabinets which are grouped as modules into containers and which hold storage units in a drawer-like arrangement. HARTING connectors provide the interfaces required for this modular structure: They are easy to assemble and facilitate servicing, thus making a contribution to keeping downtime within limits.

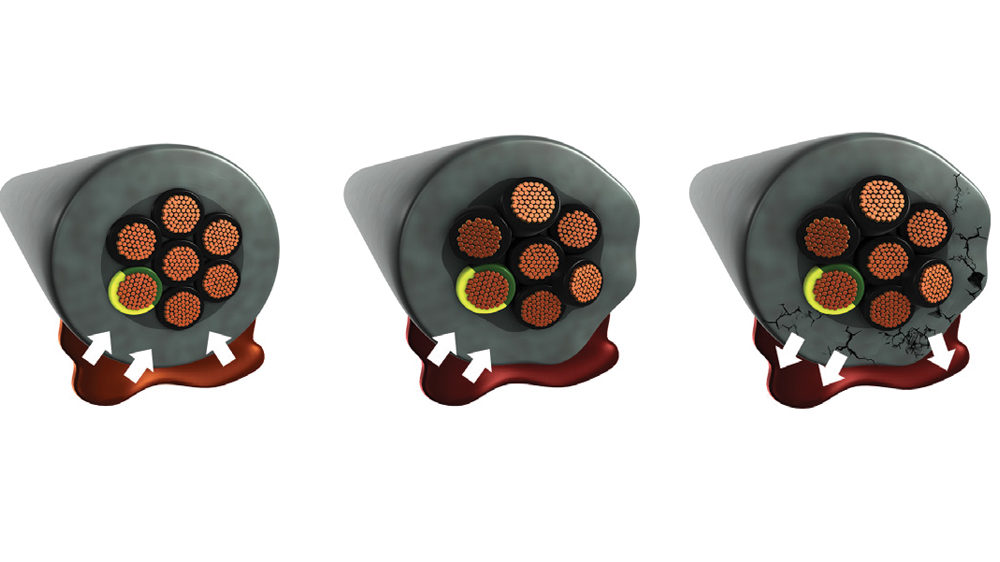

At the heart of the solution is the Han Docking Frame used with the Han-Modular connector series. The docking frame ensures that the push-in contact between the storage units is close and reliable. The solution manufactured by Rittal is a good example. The drawers of the storage cabinets are fitted with two Han 200 A modules for power transmission, supplemented by two Han Megabit modules for data exchange. The Han Docking Frame floats between the drawer and the busbar. It offers sufficient tolerance compensation to allow accurate and frictionless guided insertion of the pins on the drawers into the sockets of the Han 200 A module. The sockets are screwed directly to the busbar on the back wall of the cabinet, which reduces the amount of cabling required.

The Han Docking Frame qualifies as a standard for energy storage systems. In addition to the heavy current module, more than 50 other useful interfaces are available in the Han-Modular range. The different versions of the docking frame offer space for 2 to 6 modules. Grouped in a Han-Modular hinged frame the modules can be integrated in the storage unit’s drawer system to meet the requirements of an application. The modular range includes modules for up to 200 A, high density signal modules, every commonly known Ethernet interface and other robust communications interfaces.

Thanks to their modular design, the size of battery storage systems can easily be scaled up or down. Using the Han Docking Frame standardises the construction of the battery storage cabinet. Pre-assembled storage modules can quickly be combined into storage cabinets and much less cabling is required. There are also benefits for installation in the field. Fixed cabling is still a frequently deployed alternative to a docking frame, but particularly for large numbers of cabinets it is time-consuming and costly. As a rule, modular battery storage delivers from 1 to 3 MW. Each Mwh of storage capacity requires around 80 drawers. The Plug and Play solutions with the Han Docking Frame cut the amount of effort required. The Frame even helps to save time after installation, making it easier to replace and maintain the storage units. Staff without electrical expertise can replace the storage elements easily as there is no actual installation required.

Energy storage units are a key element in the strategy to reduce and avoid CO2 emissions. Furthermore, there are observable trends towards modularisation and decentralisation in all the sectors involved in energy generation. The feasibility of storage in technical and financial terms will be decisive for its acceptance on the market. The scalability of the systems on the basis of suitable interfaces is therefore an important component in their commercialisation.

Battery storage systems are linked to energy generation systems. To be as efficient as possible, they must be able to communicate freely with the other components in these and with distribution systems. HARTING offers a portfolio of other components which can play a part in an integrated solution: Switches used with pre-assembled patch cables from HARTING provide the energy management system with the means to communicate externally. Current sensors allow the quality of the current to be monitored, at the inverters for example. PCBs which guarantee communication with other components are used to manage inverters and storage. Reliable options for connecting the internal controller of a battery storage system in this way are offered by PCB connectors in the har-flexicon and har-flex range. Authored by__Ingo Siebering, Industry Segment Manager Energy, Global Business Unit Electric

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi