Stage set to boost manufacturing prowess

June 30, 2016 2:34 pm

With the government encouraging and arranging various B2B meeting forums, at least the initial ground-work in terms of sector visibility, potential assessment, etc has been done.G.K. Pillai, Managing Director and CEO, Walchandnagar Industries Ltd

Procedural and operational reforms have been a positive outcome of “Make in India” campaign. However, G.K. Pillai, Managing Director and CEO, Walchandnagar Industries Ltd believes that the ultimate success of the manufacturing sector depends not just on how proactive the government is but also how industry both public and private responds.

Change is in the wind“Make in India” has been a flagship initiative of the current government and in a way reflects the primacy and thrust that they want to give to the manufacturing sector in India. Over a period of almost two years that the initiative was launched, a lot of changes have happened notably:• A positive climate about manufacturing per se has been created within the country. It is for the first time in decades that manufacturing has been given the importance that it deserves especially considering India’s current phase of economic development, the need to create more employment and to ensure that the fruits of liberalisation do not remain restricted.• The past two years have definitely created more and more interest globally about investing in India in a variety of sectors – especially in strategic sectors like defence and aerospace as well as in core infrastructure sectors like power and roads. With the government encouraging and arranging various B2B meeting forums, at least the initial ground-work in terms of sector visibility, potential assessment, etc has been done. This has laid the platform for actual investments to follow in the coming years. An example of this can be seen in the announcement of various JVs, MOUs signed between Indian and foreign players in the area of defence.• Procedural and operational reforms have been a positive outcome of this campaign. An example cited could be that of significant streamlining of licensing procedures, requisite DIPP approvals and environmental clearances in getting industrial licenses. Also the right intent that has been signalled in making Goods and Services Tax (GST) a reality along with more freedom to states to decide their own land acquisition and usage policies have made state governments more proactive in attracting manufacturing related investments.

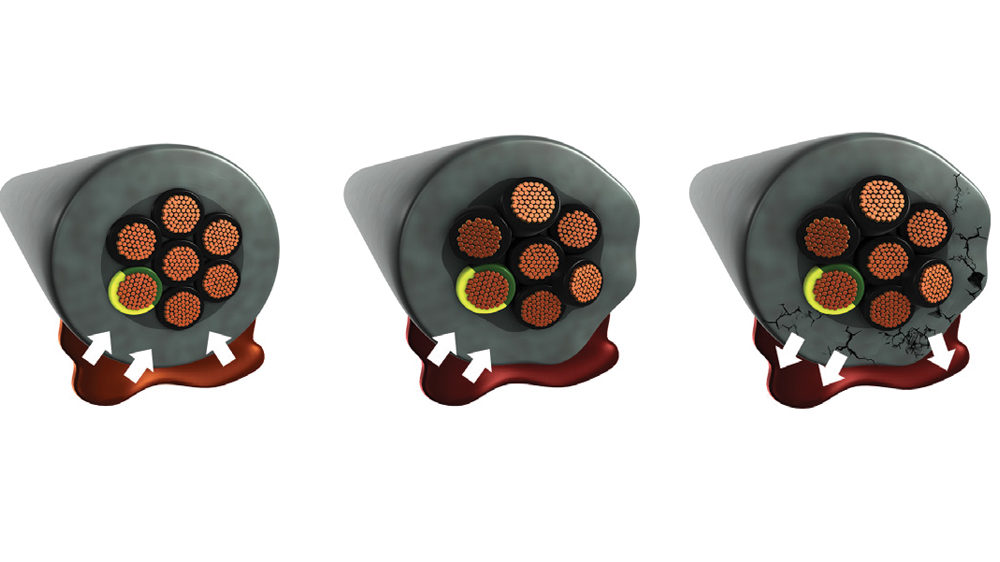

Roadmap for Indian manufacturersIt is true that the ultimate success of the manufacturing sector depends not just on how proactive the government is but also how industry both public and private responds. Indian manufacturers can leverage this initiative in the following ways:• Focus on skill development: “Make in India” does not necessarily mean low end, mass manufacturing; rather it will increasingly involve high-tech manufacturing for which the necessary skills would have to be built up by industry.• Invest in research and development (R&D), technology assimilation and constant skill upgradation (e.g. critical skills like welding, machining which are very critical to the industry like engineering).• Leverage the forums currently available (industry bodies, B2B forums, exhibitions and seminars, delegate visits to foreign countries) to seek the right partnerships with both domestic and global players in their respective areas.• Align business plans with thrust areas indicated by the government.• Participation in programs which involve public-private partnerships which are being increasingly encouraged.

India remains a stand-out economyIn the present global context, there are several factors that go in India’s favour especially as far as manufacturing is concerned:• Favourable demographics – especially in terms of adequate numbers of skilled blue collared workers with a medium to low range of labour cost as compared to other countries.• Evolved managerial and technical talent, many established industrial houses and a tradition of manufacturing across a broad spectrum of industries – for both industrial as well as commercial goods.• Centres of excellence in education – especially technical education (professional and vocational) which assures a steady stream of technically qualified engineers, technicians, etc.• Political stability at the centre and across states, proactive government policies.• Huge domestic demand – with an aspiring middle-class.• Upcoming infrastructure in terms of roads, ports, airports and associated logistics.• Stable macro-economic factors like inflation, exchange rate, fiscal deficit, interest rates and a balanced budget.

In fact all this comes at a time when globally there are very few instances of large economies showing robust and sustainable growth. With recovery in US being tepid, Euro Zone not having come out fully from its stupor (and faced with the impending threat of Brexit), political instability and terror threat in West Asia and slowing down of China, India remains a stand-out economy in the present context

Major roadblocksThere are two major roadblocks to “Make in India”:• Lack of substantial pick-up in new investments: A hang-over of additional capacities built up over the earlier years and a concomitant lack of corresponding demand has led to creation of stress in the balance sheets of corporates and also of lenders (banks). This has become a major roadblock in today’s context. The answer to this is two sided – on the government’s part, it has to lay down appropriate policies which are consistent in their application e.g. flexibility of labour markets, bankruptcy law reforms, better visibility to industry regarding government’s thrust areas going ahead (so that the right investments can happen). On the industry’s side, it is essential that there is faster liquidation of non-core businesses and re-deployment of freed up resources (financial, manpower, land, etc) in core areas.• Infrastructure: No amount of intent can help if supporting infrastructure in terms of power, railways, roads, ports, airports, highways, urban infrastructure, etc doesn’t keep pace with the growth aspirations of the nation. Stringent monitoring of critical infrastructure projects, adequate budgetary support, right implementation of public-private partnerships, more reforms in areas like land acquisition and usage would go a long way in creating bedrock for economic development to follow.

Walchandnagar Industries and “Make in India”Walchandnagar Industries (WIL) has lived by the paradigm of “Make in India” since its inception 108 years ago:• WIL has been one of the foremost players in private Indian industry to support the Government of India in its strategic and core needs in the domains of energy, nuclear power, defence and aerospace.• Through its expertise in engineering and niche manufacturing, WIL has been successful in delivering products of immense technological sophistication – nuclear power plant equipments, marine gearboxes, weapon systems, components of space launch vehicles, etc to various customers like NPCIL, Indian Navy, ISRO, Bharat Dynamics Ltd, DRDO/DRDL, etc.• The focus of the organisation (which was founded by the patriotic industrialist Seth Walchand Hirachand) has always been on India becoming self-sufficient in core sectors of the economy. This has been the guiding principle during our evolution as an organisation.• WIL has created an ecosystem around its plant at Walchandnagar (130 km from Pune). With a township for its managers and skilled workers and a base of ancillary industries around the area in which it is located, WIL has one of the earliest exponents of the public-private partnership in a thought process like “Make in India”.• With a presence today in many core sectors of the economy with a particular focus on strategic areas like defence and nuclear, WIL is well poised to contribute to the “Make in India” paradigm in a big way.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi