Pramet unravel turning dilemma with new ranges

January 6, 2016 11:43 am

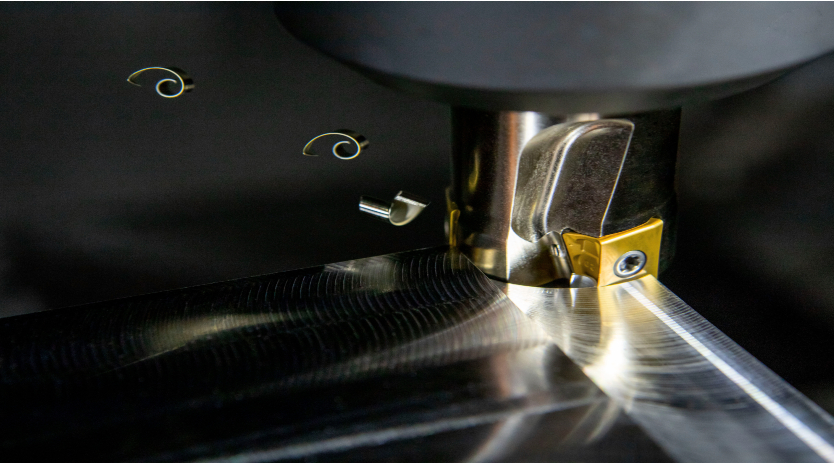

Pramet has introduced two new positive geometries and grades for turning applications in difficult to machine materials.

Suitable for a variety of turning applications, the SF and SM geometries have been launched to support the machining of materials such as high temperature alloys and stainless steel.

Part of Dormer Pramet’s second product launch of 2015, the SF geometry features a sharp, positive rake of 14.5 degree. It is suitable for finishing applications in continuous cut with very low forces. The SM geometry has a positive rake of 13 degree and is a wear-resistant, universal geometry for medium machining (finishing up to roughing) and suitable for continuous and interrupted cut.

Both geometries are available in a variety of grades and have been designed to promote low cutting forces and prevent work-hardening. This helps to reduce the risk of vibration when turning thin-walled components.

In addition to the new geometries, two new turning grades have been unveiled by the global cutting tool manufacturer.

The PVD coated T6310 grade features a special sintering process which enhances cutting edge reliability and strength. Its new substrate with intermediate Cobalt content provides additional hardness and increased abrasion resistance to offer greater reliability and prolonged tool life.

The T6310’s triple coating provides durability for higher cutting speeds used when machining stainless steel, heat-treated and hardened materials. It is suitable for use with the new SM and SF geometries, as well as Pramet’s existing NF and RM geometries, with a total of 89 inserts now available.

Josef Bittner, product manager for turning at Dormer Pramet, said, “The thermal conductivity of stainless steel, nickel and titanium tends to be low, but with high cutting speeds and feeds required during machining, the cutting edge can quickly become overheated, shortening tool life.”

Machining with coolant reduces these effects, but the constant change of temperature at the cutting area causes heat stresses, resulting in thermal cracks and, again, poor tool life.

“We therefore saw a need to create a new grade with the right combination of substrate and coating to enhance resistance to thermal cracking. Our new T6310 grade achieves that objective,” said Josef.

Meanwhile, Pramet’s new H07 uncoated grade offers good heat conductivity and high wear resistance required for turning titanium and alloys. Its fine grain substrate with low Cobalt content offers resistance to pitting as well as plastic deformation. It is available in the new SF geometry.

Josef added, “These latest products will be of use in extreme environments where they are subjected to tremendous heat and corrosion, for example in the general machining, oil and gas, automotive, medical industry, marine and power generation sectors.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.