Small, strong, smart ejectors

August 25, 2015 3:08 pm

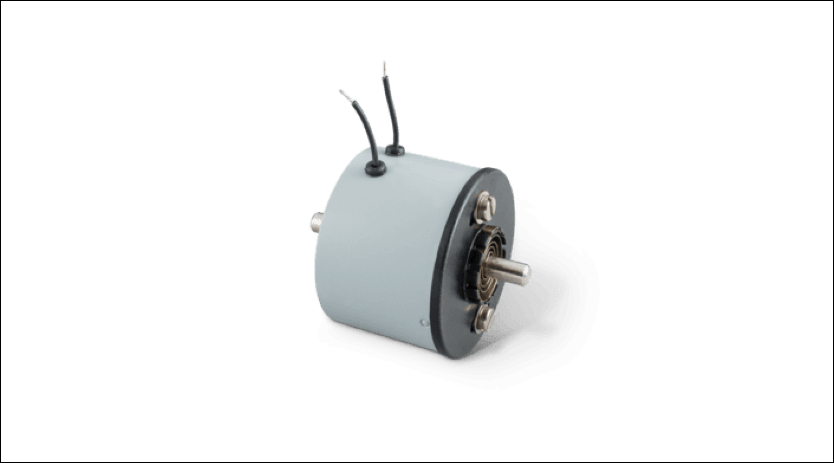

Compact design, strong performance, intelligent integrated functions – the new ejector series SCPS/SCPSi with nozzle sizes from 0.7 to 1.5 mm raises the bar for efficiency in automation. The ejectors, introduced by Schmalz, are used in different industries including packaging, metal, plastics, glass and solar power.

At just 18 x 105 x 99 mm and with a suction rate of 65 litres per minute and a pressure range from two to six bar, these compact solutions are ideally suited for handling suction-tight and slightly porous workpieces. This makes them perfect for use in systems with limited space and highly dynamic processes with demanding requirements.

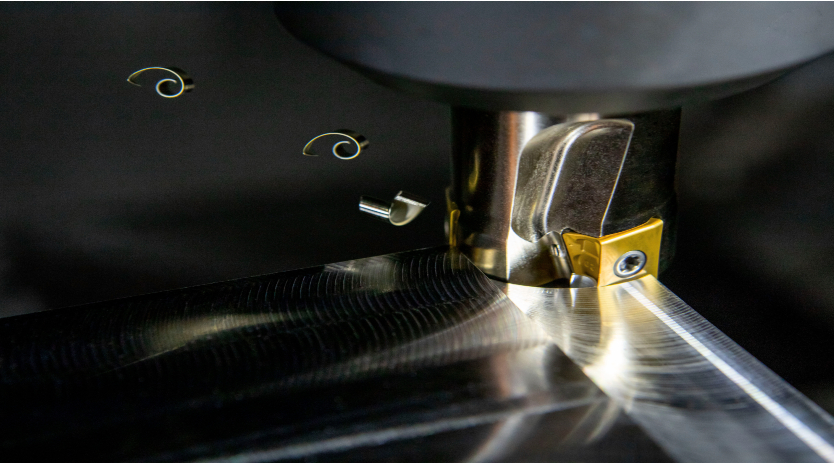

The SCPS and SCPSi compact ejectors are equipped with more functions. The series is also optimised in terms of fluid technology: high-performance nozzles ensure that the ejector can generate an extremely high vacuum in fractions of a second. Together with extremely fast valve switching times, the high-performance levels of the new series ensure extremely short cycle times for applications up to well over 200 cycles per minute. Furthermore, the ejectors are also equipped with an automatic air saving function for economic operation. This reduces the amount of compressed air consumption by up to 80 per cent compared to similar ejectors without controllers, which also reduces operating costs. If no vacuum is required at the moment, this function is simply switched off by the compressed air generator. At the same time, it permanently monitors the vacuum level and reacts immediately to extreme drops.

In order to adapt the ejectors optimally to the workpiece and to the process, Schmalz has equipped them with an automatic, strength-adjustable blow-off function. This allows for even quicker pickup of parts and increases the overall dynamics of the process. The particularly user-friendly display is another one of the features of the compact ejectors. It provides the operator with information about the most important vacuum parameters at a glance. At the same time, large buttons and a clear menu structure make it easy to operate. With the standard IO-Link interface, of the SCPSi, the operator can perform parameterisation and diagnostics on the ejector from the central system controller.

The SCPSi ejectors also feature an integrated condition monitoring function. This function continuously measures and monitors the leak-tightness and the vacuum level of the vacuum system. The operator can recognise errors early on and can fix them before they lead to system downtime. The vacuum generators measure all of the important energy and performance data and communicate it to the higher-level field bus systems via the existing IO-Link master. This allows the system operator to read out, monitor and optimise the data in his or her control system. This reduces energy consumption, increases system availability and makes it possible to design the system based on performance. Furthermore, the compact and durable unit can be installed directly on the handling system. This simplifies installation and opens up more space.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.