We prioritise networking and automation to improve production performance

July 7, 2023 6:41 pm

According to Vishal Deore, Director at Kjellberg, the Kjellberg eService plays a crucial role in ensuring the reliability of the production process. The service provides remote diagnostic and monitoring capabilities, as well as regular updates that help maintain the overall reliability of the system.

Please provide information on the features and advancements of the new Q series plasma cutting system.

2022 was an excellent year for us as it marked the 100th anniversary of Kjellberg in Finsterwalde. The journey began in 1922 with a modest facility dedicated to the production of welding electrodes and welding generators. Fast forward a century, Kjellberg Finsterwalde has has developed into a major global player, with our products and technologies used all over the world. One aspect that fills us with immense pride is that everything we create is “Made in Germany,” specifically Finsterwalde. To mark this significant milestone, we celebrated with our valued customers and partners at the EuroBlech, acknowledging that we couldn’t have achieved the success we have today without their support.

Our new Q 4500 plasma power source is the most powerful plasma cutting system in our Q series, combining high-precision plasma cutting at the highest level with the complex requirements of Industry 4.0 standards.

How do you approach addressing significant concerns and priorities of your customers?

Our customers place great importance on reliability and efficiency, which we prioritise by delivering our renowned Kjellberg quality – we ensure this for our partners and customers. In today’s market, our customers have high expectations of plasma-cutting machines, seeking maximum availability and exceptional productivity. They understand that the variable costs associated with a cutting system play a vital role in achieving these goals.

What are the current trends in the plasma cutting and welding markets?

The key words are sustainability and digitalisation. Innovation has shaped the history of our company. We are constantly optimising our plasma-cutting machines for use in smart factories. Another important goal is, of course, the sustainable use of our machines. The latest developments in inverter power source concepts and torch technology developments ensure a consistent reduction in energy and gas consumption compared to other cutting technologies. We want to pay particular attention to low CO2 emissions. With our Q series we are making very good progress towards achieving these goals with our Q series.

What are the latest advancements in product solutions and technologies being introduced to the plasma cutting and welding market?

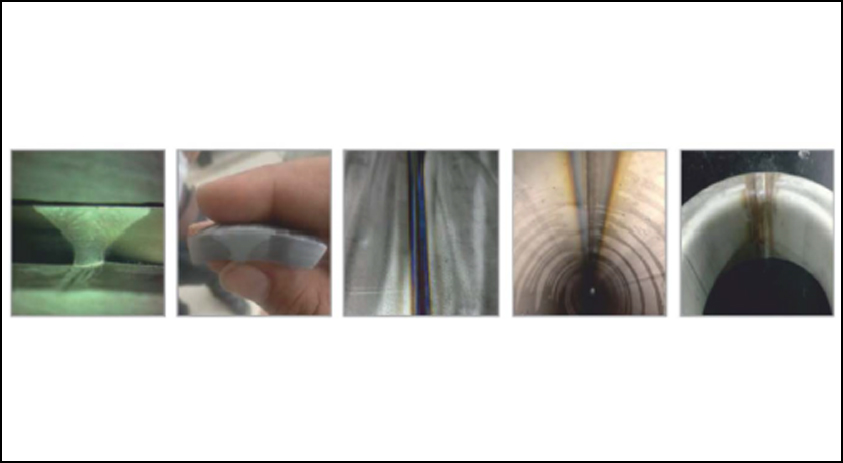

We are very proud of our latest addition to the plasma cutting , the Q 4500, which was launched at. Designed for digital production, this state-of-the-art machine boasts an impressive cutting capacity of up to 450A, efficiently cutting materials up to 120mm thick at high cutting speeds. The Q 4500 excels in precision plasma cutting and marking, offering users exceptional performance and flexibility. This machine effectively reduces costs and increases overall efficiency by achieving higher cutting speeds.

To improve operator convenience and accessibility, we have developed the browser-based HMI, the Q-Desk, which provides real-time process data and information on all system components. This feature can be accessed on standard devices such as smartphones and tablets, allowing users to monitor operations from anywhere. In addition, the Q-Desk supports data transfer and processing using the MQTT protocol via the Ethernet interface. This enables seamless integration and use of process data.

Furthermore, our Kjellberg eService ensures reliability throughout production by providing remote diagnostics, monitoring, and regular updates. This comprehensive service facilitates efficient maintenance and support, ultimately ensuring smooth operations for our customers.

How do you perceive the current global business climate for sheet metal working professionals?

Similar to companies around the world, our organisation has faced significant challenges due to the ongoing Covid pandemic, which continues to impact on global operations. In addition, the conflict in Ukraine and the Covid situation in China have introduced new complexities. Given the importance of international markets to our industry, ensuring the continued success of our products despite political fluctuations.

What challenges do you anticipate regarding delivery capability and supply chain issues?

Ensuring our delivery capability is a major challenge we are currently facing. However, we see this challenge as an opportunity for growth. Our significant advantage lies in our extensive production depth, covering assembly units and parts. This factor has proved crucial in maintaining our resilience, particularly in managing supply chain issues. In addition, our large inventories allow us to respond quickly to market fluctuations.

In the future, we plan to reduce our dependence on the public electricity grid by implementing our photovoltaic systems. This strategic decision will increase our energy self-sufficiency and contribute to cost savings.

What is your perspective on the impact of Industry 4.0, big data, and emerging technologies such as artificial intelligence, augmented reality, and Virtual reality?

Our new Q series power sources uses EtherCAT for efficient process communication, enabling seamless interaction between the power source, guiding system, and other production components. In addition, the manufacturer can perform remote updates and diagnostics via VPN connection, improving convenience and support. These advancements focus on networking and automating the production process, ultimately improving system availability.

Furthermore, we provide users with valuable tools for visualisation, operator assistance, preventive maintenance, and troubleshooting, that can be accessed from anywhere in the world on various devices such as smartphones and tablets in a secure environment.

As a member of the Industry Business Network 4.0 e.V. association, Kjellberg Finsterwalde is actively involved in the development of solutions for new products and existing plants. Our aim is to enable existing users of power source to benefit from the advantages of digitalisation, networking, and streamlined operation.

What is your strategic and technical vision for the future?

At Kjellberg we are committed to developing our technologies and providing innovative and high-quality products, even though the core product has changed over the years. Our current goal is to continue to develop the plasma cutting process. Our customers want more powerful machines that are as well equipped and flexible as possible for future tasks, always combined with digitalisation. This creates new user requirements and expectations that we have to meet with our technologies. On the other hand, digitalisation offers us with new opportunities to further develop our products, especially when it comes to linking complete production chains and systems. Another aim for the future is to expand our marketing activities. We want to establish representative offices around the world and use more digital tools in our marketing activities.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.