CajoMakeBright: the sustainable product marking technology developed for the packaging industry

July 3, 2023 5:34 pm

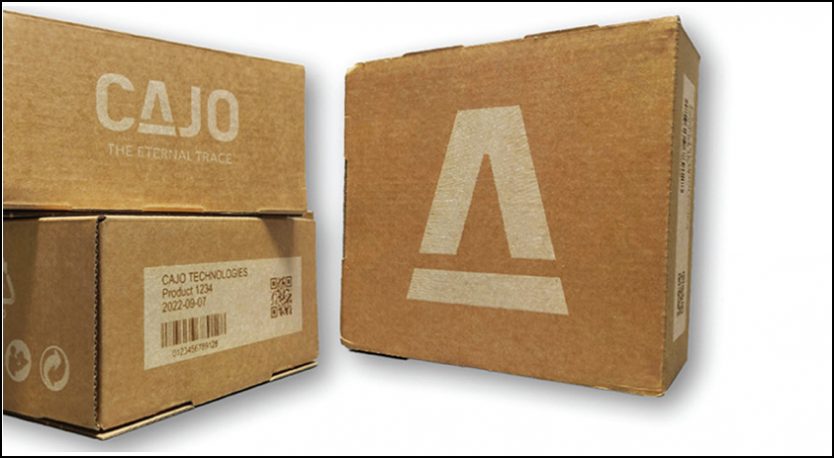

CajoMakeBright by Cajo Technologies is a revolutionary new way to produce precise and permanent product markings on cardboard more sustainably than ever before.

Cajo Technologies’ innovative, patent-pending new laser marking technology enables firms to enhance production procedures and reduce operating expenses drastically. Manufacturers now have the competitive advantage they’ve been looking for in a highly competitive industry due to CajoMakeBrightTM. Comprehensive laser marking systems and intelligent software is available for virtually any product marking purpose. With Cajo’s powerful control board, the laser marking system gives manufacturers complete control of the marking process.

CajoMakeBright is designed to replace the need for ink or labels for marking tertiary packaging. As proven by an insightful study by Macon Ltd., in 2020, replacing an inkjet marking method with a Cajo Laser provides manufacturers with a 90 percent carbon footprint reduction over industrial labelling. In addition, choosing Cajo Laser offers manufacturers numerous other benefits. CajoMakeBright lightens the surface for text and logos and then darkens modules or bars in 1d and 2d codes to ensure maximum readability, achieving A grade results against ISO 29158 (AIM-DPM). The patent-pending technology is the most sustainable marking solution in the world offered to Packaging Industry manufacturers and exclusive to Cajo.

Cajo’s patented technology and intelligent laser marking systems are designed to improve all possible production processes, replacing outdated and wasteful marking methods globally with cost-efficient automated solutions.

The company’s success has been built on recognising diverse customer challenges and developing superior solutions to overcome these obstacles. Cajo’s high-quality and environmentally friendly laser marking systems are already sold to and running in more than 60 countries worldwide. Among Cajo’s customers are many international market leaders, with more manufacturers choosing lasers every day.

Cajo’s remarkably cost-efficient lasers and flexible software solutions are available for all industrial marking purposes, covering the needs for traceability, identification, and product markings with an extremely short payback time. In addition, laser marking is the most cost-effective and sustainable way to mark virtually any material. Cajo lasers replace outdated and wasteful marking methods, helping manufacturers around the world improve their production processes and save not only costs but the environment as well.

Sustainable technology replaces inkjets and labels

Removing consumables, such as ink, ribbon, and labels, from the production process enables manufacturers to reduce operating costs and frees up cash in stocking these extra items. Laser is a reliable alternative with only a few moving parts. This means lasers do not require a significant stock of spares. This further increases the savings and convenience manufacturers gain by choosing a laser.

Laser is generally recognised as the most reliable coding and marking technology, which means fewer breakdowns and less maintenance, both planned and unplanned, required. Very few parts are susceptible to wear and tear in a laser with no pumps, gears or pulleys needed. A reliable laser allows manufacturers to improve line performance and OEE significantly. Manufacturers can complete their orders smoothly in line with schedules improving delivery performance.

High-quality, precise and permanent markings

Reliable Cajo lasers achieve high-quality marking results time and time again. The quality of laser-marked codes remains consistently the same, enabling vision applications to work best with lasermarked products. As a result, the number of rejects for unreadable codes will be significantly reduced. Reducing waste helps with costs and efficiency and boosts sustainability – fewer scrapped products mean fewer resources wasted.

Fast marking on the fly for mass production lines

Laser has a distinct advantage over print and apply labellers, as they require manufacturers to regularly stop the production line to replace rolls of labels and ribbons and then clean the rollers. This can add up to hours of lost production per month. Laser, on the other hand, is an extremely low-maintenance, cost-effective and fast modern solution for manufacturers who wish to improve their production processes.

Cajo offers several laser marking solutions that can be integrated smoothly into high-speed production lines or used as stand-alone workstations for manually loaded parts. Superior Cajo lasers ensure fast marking on the fly with precise and permanent markings made possible even for challenging materials.

In Cajo’s over a decade-old history, more than 4,000 materials have been tested and optimised for a comprehensive parameter library for easy use.

CajoMakeBright™ – The Brightest Technology of Tomorrow Here Today

Choose cajo MakeBright™ for a brighter tomorrow.

Manufacturers who want to improve line performance, reduce operational costs and money tied up in stock, whilst making a positive change for the planet can get the comprehensive marking and coding solution from Cajo. Choose Cajo for intelligent product marking.

(VIDEO https://www.youtube.com/watch?v=DfDMvLx2GTk)

To know more visit: cajotechnologies.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi