Smart sensors, advanced analytics and machine learning optimise performance

June 9, 2023 1:55 pm

L. Krishnan, Managing Director, TaeguTec India, says we have adopted industry 4.0 practices, such as IoT, AI, robotics and automation, to optimise our manufacturing processes, improve quality and reliability, reduce costs and resultantly, environmental impact.

How does TaeguTec India’s range of tailor-made machining solutions and local capabilities enhance productivity and cost efficiency?

TaeguTec India is a prominent supplier of advanced machining solutions across various industries, including automotive, mould and die, aerospace, and power generation. Renowned as the preferred tooling partner in the industry, TaeguTec offers a comprehensive range of turnkey solutions tailored to meet the specific needs of its customers, enhancing productivity and cost efficiency on the shop floor. Founded in 2000 in Bangalore, TaeguTec India specialises in Tungsten Carbide cutting tools, including inserts and holder bodies for turning, milling, drilling, grooving, and parting applications. Additionally, they provide solid carbide tools and tooling systems.

Working in tandem with TT Korea’s extensive research and development initiatives, TaeguTec India possesses local capabilities to address the unique requirements of Indian customers through customised products and innovative solutions, earning widespread acclaim.

What methods do you use to assess the effectiveness of your company’s sustainable manufacturing initiatives?

TaeguTec India has always been firmly committed to environmental, health and safety (EHS) management and has implemented effective EHS systems aligned with ISO 14001:2015 and ISO 45001:2018 standards. We have employed several approaches to evaluate the effectiveness of TaeguTec India’s sustainable manufacturing initiatives.

Evaluating the EHS performance indicators such as energy consumption, greenhouse gas emissions, waste generation, water usage, occupational injuries and illnesses, etc. These indicators can be compared with the EHS objectives and targets set by the organisation and with the industry benchmarks to assess the progress and improvement of EHS performance.

Conducting regular audits and reviews of the EHS management system to ensure its continuing suitability, adequacy and effectiveness. The audits and reviews can identify the strengths and weaknesses of the EHS system and the opportunities for improvement and corrective actions. The audits and reviews can verify compliance with the EHS legal and other requirements applicable to TaeguTec India.

Engaging with stakeholders such as customers, employees, suppliers, regulators, community members, etc., to obtain feedback and suggestions on the EHS aspects of TaeguTec India’s products and processes. The stakeholder engagement can help understand their expectations and needs and communicate the EHS achievements and challenges of TaeguTec India.

Please elaborate on the technological advancements your company has implemented in its business practices.

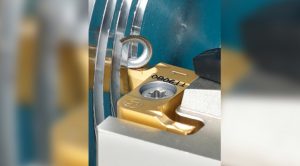

Our company has made significant advancements in technological innovation. We have been constantly developing and launching new and innovative products that offer high performance, efficiency, and productivity for different machining applications. TaeguTec recently unveiled its new line of technologically advanced cutting tools, WinSFeed, to its business partners. These products include new grades, geometries, and coatings that handle various materials and extreme working conditions.

We have also transformed into a digital-led company, leveraging cloud capabilities to enhance our productivity, efficiency and innovation. We use cloud-based platforms and tools to manage our operations, collaborate with our partners and customers, and access real-time data and insights.

Furthermore, we have adopted industry 4.0 practices like IoT, AI, robotics and automation to optimise our manufacturing processes, improve our quality and reliability, and reduce our costs and environmental impact. We use smart sensors and devices to monitor and control our machines and equipment, and we use advanced analytics and machine learning to optimise our performance and outcomes.

These technological advancements empower us to deliver superior products and services to our customers and to stay ahead of the competition in the dynamic and challenging market. We are committed to continuous improvement and innovation and look forward to exploring new opportunities and possibilities leveraging technology for further growth.

What are the challenges the manufacturing sector encounters while implementing sustainable manufacturing practices?

As a company committed to sustainability, TaeguTec India acknowledges the importance of implementing sustainable manufacturing practices. Sustainable manufacturing creates products or services that minimise environmental impact, conserve natural resources, and enhance social and economic value.

Balancing the economic, environmental and social aspects of sustainability

Implementing sustainable manufacturing practices involves:

• Reducing environmental impact.

• Improving social benefits of products and processes.

• Maintaining economic viability and competitiveness of the business.

This can be challenging as some sustainability initiatives may entail higher costs, lower productivity, or lower profitability in the short term. Manufacturers must find ways to optimise their trade-offs and align their sustainability goals with their business strategy and stakeholder expectations.

Adopting new technologies and innovations that enable sustainable manufacturing requires using advanced technologies and innovations that can improve the efficiency, performance, and quality of products and processes while reducing the consumption of energy and resources, the generation of waste and emissions, and the risk of accidents and hazards. However, adopting new technologies and innovations can be challenging as they may require significant investments, changes in infrastructure and equipment, skills development and training, and regulatory compliance.

Managing complex and diverse value chains that involve multiple stakeholders

Sustainable manufacturing requires collaborating and coordinating various stakeholders across the value chain, such as suppliers, customers, regulators, employees, communities, etc. These stakeholders may have different interests, needs, and expectations regarding sustainability. Manufacturers must manage their relationships with these stakeholders effectively and transparently while ensuring their products’ and processes’ quality, traceability, and security. By implementing these strategies, TaeguTec India aims to overcome the main challenges the manufacturing sector faces when implementing sustainable manufacturing practices. The company believes that sustainable manufacturing is not only good for the environment but also good for business.

What role is played by 3D printing in leveraging complex equipment part manufacturing?

Metal parts are increasingly being manufactured using 3D printing, especially not metallic ones. Some local machine tool makers are also producing 3D metal printers locally. This could enable faster production of MRO spares and integration into the OEM supply chain. 3D printing is expanding its applications beyond aerospace to sectors such as medical implants, general engineering and specific automotive areas. It also has great potential for creating tool bodies with complex coolant channels. The industry will eventually find a complementary niche along with traditional manufacturing.

Currently, this is in use in limited to small batch production and in future, we can see this adapted to medium to large-scale batch production.

Please detail us regarding your company’s approach to sustainable manufacturing and the specific practices you employ to mitigate environmental impact.

We have taken several proactive initiatives towards greening the environment, maximising resource conservation, and using green energy. The company has replicated a mini forest on its campus by deploying the Miyawaki technique of afforestation. It is a zero-discharge company, completely self-reliant regarding water usage, owing to reprocessing and rainwater harvesting. The factory has a half-a-million-litre storage capacity for rainwater, which has helped the company become self-sufficient and water positive. We are actively transitioning towards greater utilisation of green energy sources within our portfolio and have achieved a significant milestone.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.