AMF Zero-Point-Systems for set-up-time reduction in CNC metal cutting

February 3, 2023 2:12 pm

ZPS is also used in grinding, assembly, turning, EDM, additive manufacturing (3D printing), etc.

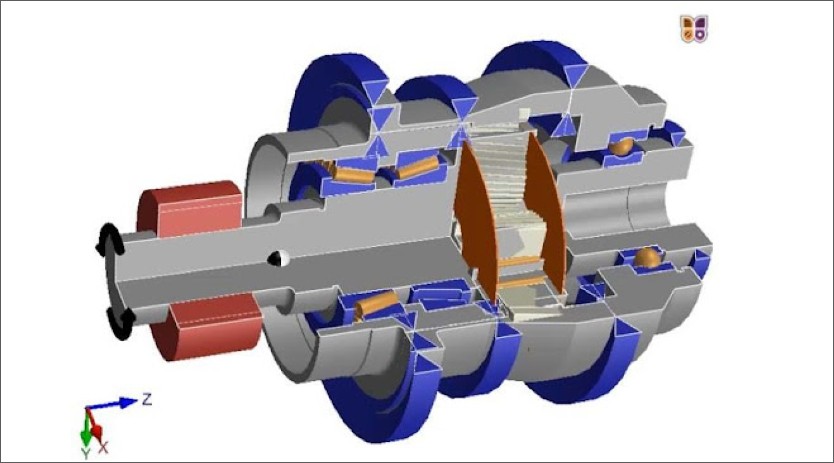

The patented and globally accepted AMF – Zero-Point- Systems are used for set-up- time reduction in CNC metal and non-metal cutting fixtures. Applications of using ZPS are numerous. Besides fixture clamping, direct clamping of massive workpieces with ZPS avoids additional fixturing and distortion-free machining of 5 sides in a single set-up, which also increases the quality of machining and saves a lot of setting/ clamping time. ZPS is also used in the grinding, assembly, turning, EDMs, additive manufacturing (3D printing), etc. Repeatability is within 0.005 mm. Clamping modules have high holding and pull-in/locking forces.

The module is opened pneumatically with 5 bar or hydraulically with 50 bar and mechanically self-locked. The clamping module connection can be disconnected once clamping is achieved. Mechanical clamping and mechanical de-clamping modules are also available.

Locating and clamping in one step.

Blowout is in-built and is a standard option in all modules to prevent heavy chips from falling on modules. A special conical pull stud screw helps load and unload fixtures quickly without collision beyond 45deg C. Multiple balls help clamp circumferentially to counter-cutting forces from 360 deg C.

ZPS characteristics include-

• High alloy, hardened tool steel- and no corrosion,

• Weight carrying capacity of modules up to 6 tons,

• Compact in design,

• Less number of parts, friction, less sliding of parts increase the life of the product,

• Easy to maintain and service. Extensive range of Clamping modules from dia18- 148 mm, pulling force from 0.1 kN-40kN and holding force from 1kN-105kN respectively.

AMF offers Zero point systems for automation where feedback on the function of modules is an absolute necessity.

For more information, visit: ANDREAS MAIER Workholding Technology Pvt. Ltd. Hall 2B/Stall A101B www.amf.de

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.