Interstellar Lab unveils ‘BioPod’- created off Dassault Systèmes’ 3DEXPERIENCE Platform

July 2, 2021 3:54 pm

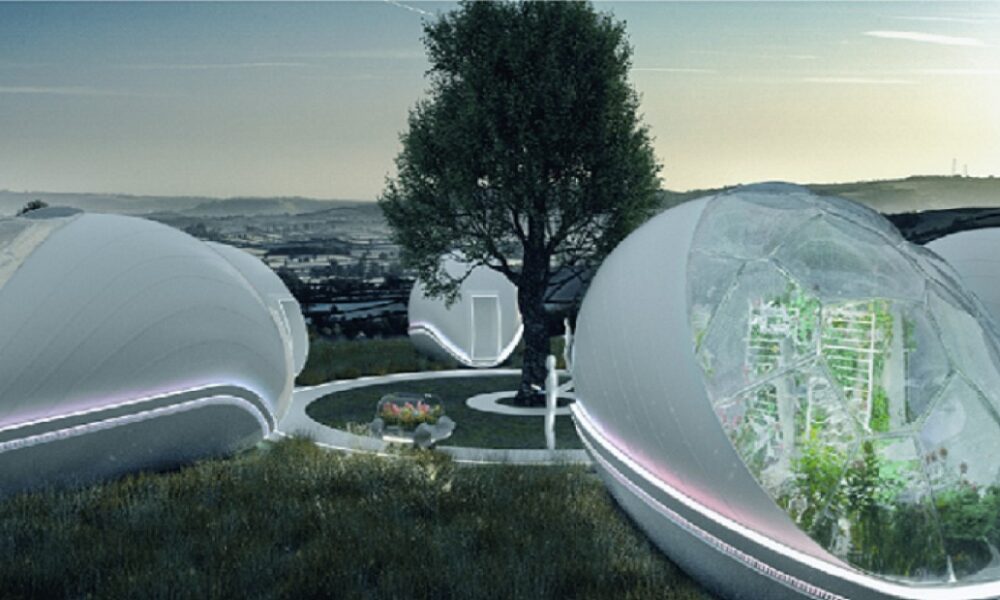

Interstellar Lab used a virtual twin experience to simulate, test and optimise the performance of BioPod’s dome and biological systems.

Taking one step closer to life on Mars, Dassault Systèmes recently announced that Interstellar Lab, a research company creating closed-loop controlled environment habitats and biospheres generating and recycling food, water and air. It used the 3DEXPERIENCE platform on the cloud to efficiently design and develop its first prototype, BioPod. This controlled environment food production system advances its mission to build space-ready stations containing the infrastructure and resources to support human life sustainably on Earth, the Moon and Mars.

Interstellar Lab used the “Reinvent the Sky” industry solution experience based on the 3DEXPERIENCE platform to seamlessly collaborate, and rapidly optimise and validate its designs. In one digital environment providing secure and instant access to the latest project data from anywhere at any time, team members in France and the U.S. combined their expertise and used a virtual twin to simulate and test the performance of BioPod’s structure in extreme climates, as well as that of its biological systems such as the optimal levels of oxygen, carbon dioxide and light levels for plants to grow.

“Climate change is a real emergency for Earth and we only have a small window to bring about positive change. We are developing a new framework for sustainable living on Earth and a testbed for future space missions,” said Barbara Belvisi, Founder and CEO, Interstellar Lab. “The 3DEXPERIENCE platform enables us to have the most efficient working processes and avoid reworking designs from scratch. As we progress to the next stage, the platform’s program and project management capabilities will be invaluable to us for storing and retrieving design knowledge and managing the product lifecycle effectively.”

As BioPod evolves, Interstellar Lab will use the virtual twin to experience and monitor the dome’s operations and maintenance, and gather data around food production and the environment. The 3DEXPERIENCE platform will also facilitate communication with suppliers as the company designs future modules and scales up manufacturing and outsourcing, and enable Interstellar Lab to create photo-realistic renderings from BioPod’s 3D model, to communicate its vision.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.