Ways to deal with challenges in automatic screw driving system arena

April 12, 2021 5:39 pm

We are faced with challenges, finding a solution becomes a necessity. In the automatic screw feeder machine world, there are different challenges.

Space is a great challenge when it comes to automatic screw driving. An auto-feed screwdriver needs adequate space to effectively fasten in every location. Space should be enough to accommodate the tool accepting the screws. You find that fastening locations located in vertical walls and deep recesses can pose a significant issue. There are cases where the obstructions cannot be designed from the assembly. In such a case, special tools can be created to enter such areas.

Fasteners can cause a lot of issues associated with automatic screw driving systems. The screws that have internal drive recesses are great for automation purposes. When you use the best fasteners, you avoid issues related to feeding and driving. The length to diameter ratio matters a lot. We cannot avoid the wide fasteners, but we can fix screws using extended tubing that bears the very same profile like the fastener.

When you are vacuuming screws in the vibratory bowl, it is normal to generate particulates. The driving process can bring the same issue as well. With products like automatic sensors and medical devices, the generation of particulate can be an issue. Most automatic screw dispenser manufacturers have come up with great methods of cleaning the feeders. Innovations have been made to ensure that the feeder does not generate as much particulate as the drum feeders and vibratory bowls. To make things even cleaner, vacuum lines may be attached to the nosepiece, the feed track, or the hoper to ensure that the particulates are sucked up.

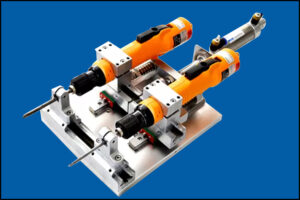

There is always a challenge involved in driving screws in tight spots. Such areas require an ideal automated screw driving system for it to be done right. There are conditions where screw presentation onto the target hole can be very challenging. Automatic screw dispenser manufacturers such as Calvin Dude have the know-how and capacity to custom make some of the automatic feeder machines to aid with your processes and guarantee an effective way of doing assemblies at all times.

For more info, Visit: https://www.calvindude.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.