Eliminating the wastewater

February 10, 2020 11:40 am

Depleting water reserves combined with the surge in demand for water has led to increased focus on wastewater management, particularly in industrial manufacturing plants. We look at the current state of industrial wastewater management and what can be done to improve it.

As India’s need for water is increasing with the growth of its population and economy, the requirement for sustainable water and wastewater management has come to the forefront. Also, with depleting freshwater resources and the widening gap between the current water demand-supply gap, there is an urgent need for improving water use efficiency and encouraging wastewater recycling and reuse.

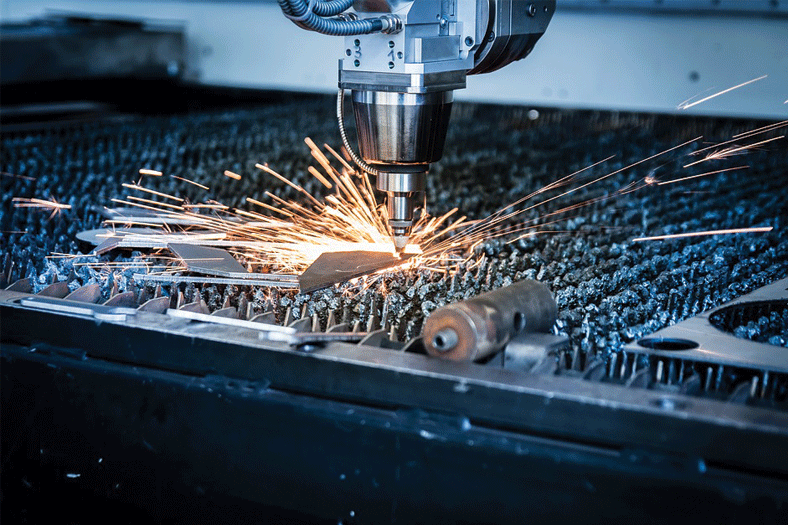

India’s manufacturing sector has seen a rapid growth, and this has resulted in increased industrial wastewater which has become one of the major sources of pollution. Industrial wastewater contains harsh effluents that negatively impact the environment and needs to be treated and reused. Since most of the manufacturing plants are in tier II and III cities, it is necessary to encourage them to opt for wastewater effluent treatment plant solutions that can treat and reuse wastewater.

Measures to recycle wastewater generated in manufacturing plants

The world is witnessing a gradual shift toward responsible manufacturing, encouraging methods to treat the wastewater generated as a by-product of their processes. They are setting up smaller wastewater treatment plants or processes within the facility to treat and reuse this water for other purposes. Ajit Jainath Singh, Sr. Vice President – Sales (CBS & IND), Grundfos India says, “The recycled water can be used to cool down machines and lubricate parts and other processes. Besides this, wastewater from industrial areas can also be treated to be reused in nearby agricultural lands and vice versa. Companies have also been moving towards achieving “Zero Liquid Discharge”status by reusing all the water they consume.”

He adds, “Grundfos India’s headquarters in Chennai is India’s first gold-rated green building (LEED certification by USGBC in 2005). Since water efficiency is an integral part of our sustainability initiatives, special efforts have been taken to minimise water use by installing water-efficient fixtures, effective rainwater harvesting and sewage treatment plant to treat 100 percent of onsite wastewater for reuse. The non-process wastewater is treated onsite and is reused for landscaping, thereby minimising the use of potable water for these applications.”

Meenu Singhal, Vice President – Industry Business, Schneider Electric India says, “It is estimated that the world population is going to double in the next 35 years. As per a World Bank report, India is among the world’s most water-stressed countries. With further increase in population, we will witness rise in water consumption levels, water scarcity, and the need for sustainable infrastructure. Since a large portion of water runs back into the ecosystem as wastewater, it can pose great environmental and health hazard if not treated. Among the multiple means for addressing water problems, one top-of-the-line option is the IoT-enabled EcoStruxure for Water and Wastewater from Schneider Electric. Based on an open, interoperable platform, it offers enhanced value revolving around safety, efficiency, reliability, connectivity, and sustainability.”

Manufacturing plants today are taking several measures to remove impurities and recycle wastewater that is generated during manufacturing processes such as dissolved air flotation, biological treatment using natural bacteria to break down carbon-based impurities, filtration through filters, carbon filters and micro filters, softening, disinfection, and deionisation.

Current scenario of wastewater management in smart factories

Singh says, “Smart factories are leveraging new technologies to boost the efficiency of their manufacturing facilities. Like manufacturing processes, wastewater treatment has also been positively impacted by these technologies. Wastewater treatment in smart factories is integrated with IoT, decentralised, and modular in nature. Grundfos, a global leader in pump solutions, uses future-forward technologies to improve wastewater management. Grundfos’ ISOLUTIONS can optimise treatment processes by using sensors to monitor flow, analyse data, and predict possible downtime. It also provides real-time monitoring at remote locations, thereby reducing the need for direct human intervention.”

Singhal comments, “The fourth industrial revolution has ushered in the era of smart factories through digitisation of processes and systems, including wastewater treatment systems. Alternatively, the stringent water quality standards, an ever-aging infrastructure, and rising operating cost have led to a greater investment in new treatment technologies and processes. There is a need for predictive analysis and decision support systems in order to operate and maintain the water and wastewater management infrastructure in smart factories.”

Digitisation brings the capability to gather operational information from all corners of water networks. Digitising the water network technology through smart water management system offers the possibility to run them more reliably and efficiently. However, it is imperative that the smart water technologies are also energy-efficient.

Singhal adds, “Water has been a strategic segment of Schneider Electric. In the Smart Water area, Schneider Electric’s technology helps to manage and optimise the operation of wastewater treatment plants. The solutions cover the entire energy cycle, from purchase, management and savings to its most efficient use, in water treatment plants, wastewater treatment plants or desalination plants along with the supply and sanitation networks.”

Technologies for wastewater management at manufacturing plant level

According to Singh, besides technologies such as IoT and automation to improve processes, next-generation pumps are available to augment wastewater treatment. He says, “Innovative technologies from Grundfos bring together intelligence, motors, hydraulics, and functionality to meet the challenges of modern wastewater, maximising the hydraulic, electrical and mechanical efficiency of pumps. These solutions can be used for end-to-end processes, from water procurement to the final stage of the water treatment.”

He further explains, “Grundfos Dedicated Controls system is delivered either as complete control cabinets or as control components for local panel assembly. Designed for the transfer of wastewater away from a wastewater pit, they can be used with standard functionality for normal needs, and also support more advanced functions for wastewater transport. It is a perfect partner in any storm water installation or flood control installation. When used with frequency converters for the pumps, it can optimise energy consumption. It can also be used for commercial buildings, as well as municipal systems.”

Besides these solutions, Singh says that Grundfos also offers iSOLUTIONS CLOUD for Wastewater Networks, which is a cloud-based solution to optimise operation and ease expansion or repair of the wastewater network.

Need for decentralised industrial wastewater treatment

The depleting water reserves and increasing water costs have encouraged the reuse of wastewater, which also includes industrial wastewater. This has further compelled the industries to re-evaluate their wastewater management techniques. A decentralised wastewater treatment involves a variety of approaches for collection, treatment, and reuse of wastewater. Singhal details, “As part of permanent infrastructure, the decentralised system provides a range of treatment options from simple to complex approaches. Sustainable and cost-effective, a decentralised wastewater treatment system is apt for India as it works well in rural, suburban and urban settings. This also offers long-term solution for water management if properly planned, operated and maintained.”

Singh adds, “For a country like India with landlocked areas, a decentralised system of wastewater provides the most logical and efficient way to treat water. Industries will be able to set up the infrastructure with minimum capital if it is properly designed, maintained and operated optimally. These are typically installed near the wastewater generation site and can be used to treat the water efficiently. They are a popular alternative as they are quite flexible and can be changed according to requirements of customers. In the long run, they are expected to cut costs and improve the bottom line on sustainability for industrial organisations.”

Current sewage treatment system used by industries

Though awareness about sewage treatment is rising, only one-third of India’s wastewater is currently treated, leading to the high burden of water-borne diseases and acute water shortage. States generating large amount of wastewater should consider treating 65-100 percent of their urban wastewater.

Singhal comments, “Treatment methods are often specific to the material being treated. Methods include advanced oxidation processing, distillation, adsorption, vitrification, incineration, chemical immobilisation or landfill disposal. Thousands of small-scale and bigger industrial units simply dump their waste, more often toxic and hazardous, in open spaces and nearby water sources. Over the last three decades, many cases of serious and permanent damage to environment by these industries have come to the fore.”

Singh says, “It is essential to create comprehensive sewage systems spread across the city to collect, convey and intercept waste of all to control pollution of water bodies. The conventional wastewater treatment processes are quite expensive and involve complex operations and maintenance. Due to improper design, poor maintenance, frequent electricity breakdowns and lack of technical manpower, the wastewater treatment facilities do not function regularly and properly. Apart from domestic sewage, only 60 percent of the wastewater generated by industries is treated. Considering current scenarios, effective sewage treatment has become a necessity in industries.”

Friendly government policies and Sustainable Development Goals (SDGs) oriented strategies will further help empower Indian industries to strengthen their sewage treatment processes. In the last couple of years, the government has launched various schemes to develop the sewage treatment and collection infrastructure in the country. Industries also have witnessed fresh investments and new players in the form of start-ups that are entering this space. This should provide the right impetus for industries to be more responsible for the waste generated and setup necessary steps and processes to tackle the same.

Companies have been moving towards achieving “Zero Liquid Discharge” status by reusing all the water they consume.

Ajit Jainath Singh, Sr. Vice President – Sales (CBS & IND), Grundfos India

Sustainable and cost-effective, a decentralised wastewater treatment system is apt for India as it works well in rural, suburban and urban settings.

Meenu Singhal, Vice President – Industry Business, Schneider Electric India

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

English

English Hindi

Hindi